Product Description

|

Material |

metal |

|

Standard |

ASTM, ANSI, DIN, GB, NF, ISO, BS, JIS etc. |

|

Process |

CNC machining |

|

Weight range |

0.5-2000kg |

|

Surface treatment |

painting, polishing, heat treatment, plaining etc. |

|

Machining |

As per customers’ requirements Machining center, CNC, Lathe, Milling machine,drilling etc. |

|

Size and design |

As per the customer’s drawings and requirements |

|

As per the customer’s samples |

|

|

Packing |

carton box then on wooden crate |

|

As per customers’ requirements |

|

|

Inspection |

Foundry in-house |

|

Third Party inspection available upon customers requirements |

1.Q:Are you trading company or manufacturer?

A: We are factory with more then 15years experience

2.Q: How long is your delivery time?

A: Generally it is 15-30days as we are Customized service we confirm with Customer

when place order

3.Q:Do you provide samples? ls it free or extra?

A: Yes we provide samples .for sample charge as per sample condition to decide

free or charged ,usually for not too much time used consumed machining process are free

4.Q:What is your terms of payment?

30% T/T in advance balance before shipment .Or as per discussion

5.Q: Can we know the production process without visiting the factory?

A:We will offer detailed production schedule and send weekly reports with

digital pictures and videos which show the machining progress

6.Q:Available for customized design drawings?

A: YesDWG.DXF.DXW.IGES.STEP. PDF etc

7.Q:Available for customized design drawings?

A: Yes ,we can CHINAMFG the NDA before your send the drawing

8.Q:How do you guarantee the quality?

A:(1) Checking the raw material after they reach our factory——

Incoming quality control(IQC)

(2) Checking the details before the production line operated

(3) Have a full inspection and routing inspection during mass production—

In-process quality control(IPQC)

(4) Checking the goods after they are finished—- Final quality control(FQC)

(5) Checking the goods after they are finished—–Outgoing quality control(QC)

(6)100% inspection and delivery before shipment.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Certification: | ISO9001 |

| Standard: | DIN, ASTM, GB, JIS |

| Customized: | Customized |

| Material: | Stainless Steel |

| Application: | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Samples: |

US$ 60/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do trailer spindles contribute to the adaptability and versatility of trailers in various settings?

Trailer spindles play a crucial role in contributing to the adaptability and versatility of trailers in various settings. Here’s a detailed explanation:

Trailer spindles are the components that connect the wheels to the trailer frame and axle. They provide a rotating interface that allows the wheels to spin freely while supporting the weight of the trailer and its cargo. The design and features of trailer spindles enable them to enhance the adaptability and versatility of trailers in the following ways:

- Compatibility with Different Axles: Trailer spindles are designed to be compatible with various types of axles, including straight axles, torsion axles, and independent suspension systems. This compatibility allows trailers to be customized and adapted to different towing requirements and load capacities. Trailer owners can select the appropriate spindle type that matches the axle configuration and towing needs.

- Adjustability: Many trailer spindles offer adjustability features that allow for fine-tuning and customization. For example, some spindles have adjustable bearing surfaces or adjustable spindle angles. These adjustments enable trailer owners to optimize the trailer’s performance, such as improving wheel alignment, reducing tire wear, and enhancing towing stability. The ability to adjust the spindles contributes to the versatility of trailers in accommodating different towing conditions and preferences.

- Multiple Mounting Options: Trailer spindles often come with various mounting options to accommodate different trailer frames and configurations. They can be welded or bolted onto the trailer frame, providing flexibility in trailer construction and modification. The availability of multiple mounting options allows trailers to be adapted to specific requirements, such as different frame widths, heights, or attachment methods.

- Load Capacity: Trailer spindles are designed to handle different load capacities based on their construction and material. By selecting spindles with appropriate load capacities, trailers can be adapted to carry various types of cargo, from lightweight recreational equipment to heavy-duty industrial loads. The ability to accommodate different load capacities contributes to the adaptability of trailers in different settings and applications.

- Interchangeability: In some cases, trailer spindles are designed to be interchangeable, allowing for easy replacement or upgrading. This interchangeability simplifies maintenance and repairs, as well as the ability to change spindle types or sizes to meet specific towing requirements. Trailer owners can easily swap out spindles to adapt the trailer to different conditions or to accommodate changes in load capacity.

Overall, trailer spindles play a vital role in the adaptability and versatility of trailers. Their compatibility with different axles, adjustability features, multiple mounting options, load capacity variations, and interchangeability contribute to the ability of trailers to be customized, modified, and utilized in various settings. Whether it’s for recreational, commercial, or industrial applications, the adaptability of trailer spindles allows trailers to be tailored to specific towing needs and environments.

What advantages do certain types of trailer spindles offer compared to others?

Trailer spindles come in various types, and each type offers unique advantages compared to others. Here’s a detailed explanation:

- Straight Spindles:

Straight spindles are the most common type and offer several advantages:

- Cost-Effective: Straight spindles are relatively simple in design and construction, making them cost-effective compared to other types.

- Wide Availability: Straight spindles are widely available, making them easy to find and replace if needed.

- Easy Maintenance: Straight spindles are relatively easy to maintain and service, requiring fewer specialized tools or techniques.

- Tapered Spindles:

Tapered spindles provide their own set of advantages:

- Increased Load Capacity: Tapered spindles are designed to handle higher load capacities compared to straight spindles of similar size. The tapered shape enhances their strength and load-bearing capabilities.

- Better Alignment: Tapered spindles offer improved wheel alignment as they allow for precise fitment of the wheel hub assembly. This helps in maintaining proper tracking and reduces tire wear.

- Enhanced Stability: The taper design of these spindles contributes to enhanced stability during towing, reducing the risk of wheel wobbling or vibrations.

- Drop Spindles:

Drop spindles offer specific advantages for certain trailer applications:

- Lowered Trailer Height: Drop spindles are designed to lower the trailer’s ride height, allowing for easier loading and unloading of cargo or equipment.

- Improved Ground Clearance: By lowering the trailer height, drop spindles can also improve ground clearance, reducing the risk of bottoming out on uneven terrain.

- Enhanced Aerodynamics: The lower trailer height achieved with drop spindles can improve aerodynamics, leading to potential fuel efficiency gains.

- Brake Spindles:

Brake spindles offer advantages when used with trailer braking systems:

- Integrated Braking: Brake spindles are designed to accommodate brake assemblies and provide a mounting point for the brake components, allowing for integrated braking systems.

- Improved Stopping Power: Brake spindles, when used with appropriate brake systems, enhance the trailer’s stopping power, improving overall safety during towing.

- Controlled Braking: Brake spindles provide better control and modulation of braking forces, allowing for smoother and more controlled stops.

It’s important to note that the advantages of certain types of trailer spindles may be more relevant to specific trailer applications or towing requirements. Consideration should also be given to factors such as load capacity, compatibility with other trailer components, and manufacturer recommendations when selecting the appropriate spindle type for a given application.

In summary, certain types of trailer spindles offer advantages over others. Straight spindles are cost-effective, widely available, and easy to maintain. Tapered spindles provide increased load capacity, better alignment, and enhanced stability. Drop spindles lower the trailer height, improve ground clearance, and enhance aerodynamics. Brake spindles offer integrated braking, improved stopping power, and controlled braking. Understanding the advantages of different spindle types helps in selecting the most suitable option based on specific trailer requirements and towing needs.

Can you describe the factors to consider when selecting trailer spindles for specific applications?

When selecting trailer spindles for specific applications, several factors should be taken into consideration. Here’s a detailed explanation of the factors to consider:

- Trailer Type and Purpose:

The type of trailer and its intended purpose play a significant role in determining the appropriate spindles. Different trailers, such as utility trailers, boat trailers, RV trailers, or horse trailers, have varying weight capacities, load requirements, and operating conditions. Understanding the specific trailer type and purpose helps in selecting spindles that can handle the expected loads and provide optimal stability.

- Load Capacity:

The load capacity of the trailer is a crucial consideration when selecting spindles. It is important to determine the maximum weight the trailer will carry, including the weight of the cargo or equipment. Spindles must be chosen to accommodate the expected load capacity to ensure safe and reliable operation.

- Wheel Size and Configuration:

The size and configuration of the trailer wheels are important factors in spindle selection. The spindle should be compatible with the wheel hub assembly and match the wheel bolt pattern. Additionally, the spindle may need to accommodate specific wheel sizes or tire configurations, especially in trailers where different wheel sizes are used.

- Environmental Factors:

The operating environment of the trailer should be considered when selecting spindles. For trailers exposed to corrosive environments, such as boat trailers used in saltwater, spindles with corrosion-resistant coatings or materials should be chosen to ensure durability and longevity.

- Compatibility with Axle and Suspension:

The spindle should be compatible with the trailer’s axle and suspension system. Consideration should be given to the type of axle (leaf spring, torsion, etc.) and the suspension configuration to ensure proper fit and functionality. The spindle should work in conjunction with the axle and suspension system to provide optimal stability and performance.

- Manufacturer Recommendations:

It is important to consult the trailer manufacturer’s recommendations or specifications when selecting spindles. The manufacturer’s guidelines provide valuable information about the appropriate spindle type, size, and other factors specific to the trailer model. Following the manufacturer’s recommendations helps ensure compatibility and adherence to safety standards.

- Regulatory Requirements:

Depending on the region and specific trailer application, there may be regulatory requirements or standards that dictate the selection of spindles. It is essential to be aware of and comply with these regulations to ensure legal operation and safety compliance.

- Expert Advice:

When in doubt or faced with unique trailer requirements, seeking expert advice from trailer manufacturers, suppliers, or industry professionals is recommended. They can provide valuable insights and recommendations based on their expertise and experience.

In summary, when selecting trailer spindles for specific applications, it is important to consider factors such as the trailer type and purpose, load capacity, wheel size and configuration, environmental factors, compatibility with axle and suspension, manufacturer recommendations, regulatory requirements, and seek expert advice when needed. Taking these factors into account ensures the appropriate selection of spindles that can handle the load, provide stability, and meet the specific requirements of the trailer and its intended use.

editor by CX 2024-03-01

China Professional Utility Trailer Spindle Half Stub Axle Shaft with 4 / 5 / 6 / 8 Bolt Hub

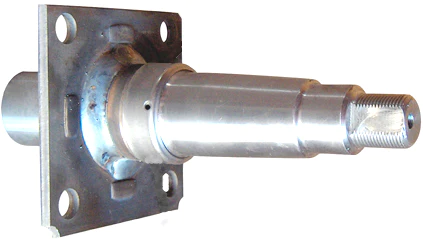

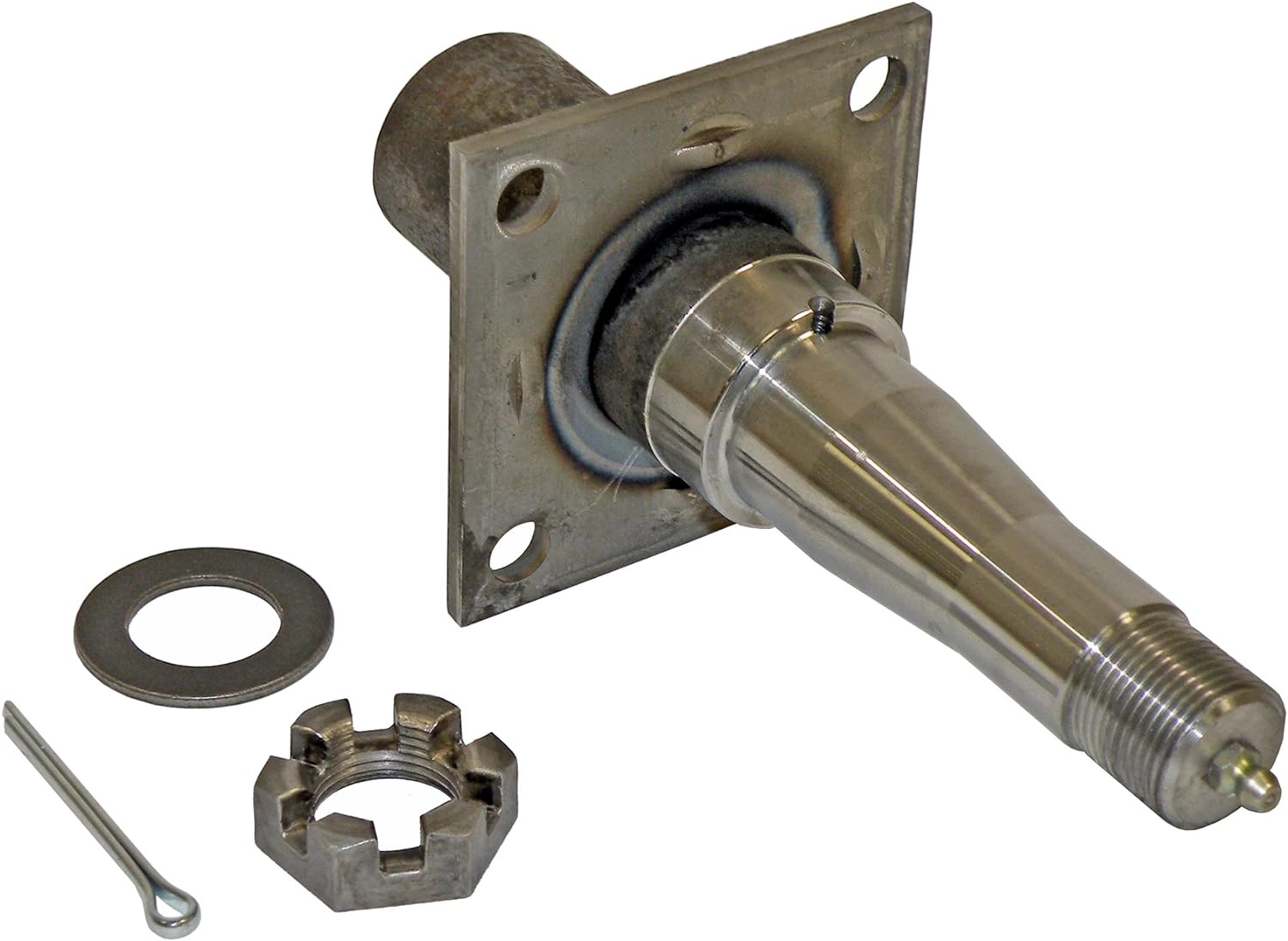

Product Description

Utility Trailer Spindle Half Stub Axle Shaft with 4 / 5 / 6 / 8 Bolt Hub

Specs:

1. Sizes: 4-4″, 5-4. 5″, 5-4. 75″, 5-5″, 5-5. 5″, 6-5. 5″, 8-6. 5″

2. surface treatment : Painted black, galvanized, e-coating, or dacromet

3. Brinell Hardness 187- 255

4. Material: SAE G3500 or as per your requests; Tensile 250MPa min.; Brinell Hardness 187-255

5. Stud: 1/2-20UNF-2A, SAE-Grade 8, Tensile 150, 000 CHINAMFG min, Proof 120, 000 CHINAMFG min.

6. Bearing: Race L-44610, L-68111, LM-67571, 15245, 14276.

Cone L-44643, L-44649, L-68149, LM-67047. LM-67048, 15123, 14125A, 25580.

Kits includes: 1. Seal | 2. Inner Bearing | 3. Inner Race | 4. Outer Bearing | 5. Outer Race | 6. Hub | 7. Dust Cap | 8. Spindle | 9. Lug nut

|

Dim(X) |

PCD(Y) |

Bolt |

Bearing |

|

192.4 |

139.7 |

6*1/2″ |

LM67048/LM11949 |

|

192.4 |

139.7 |

6*1/2″ |

L68149/LM12749 |

|

138.8 |

108 |

5*7/16″ |

LM67048/LM11949 |

|

152.4 |

108 |

5*7/16″ |

LM67048/LM11949 |

|

152.4 |

120.65 |

5*7/16″ |

LM67048/LM11949 |

|

152.4 |

114.3 |

5*1/2″ |

LM67048/LM11949 |

|

152.4 |

108 |

5*7/16″ |

L68149/LM12749 |

|

152.4 |

120.65 |

5*7/16″ |

L68149/LM12749 |

|

152.4 |

114.3 |

5*1/2″ |

L68149/LM12749 |

|

138.8 |

101.6 |

4*7/16″ |

LM67048/LM11949 |

|

183.5 |

139.7 |

6*1/2″ |

25580/15123 |

|

152.4 |

X |

5*1/2″ |

L68149/LM12749 |

101.6 mm=4 inch

108 mm=4.25 inch

114.3 mm=4.5 inch

120.65 mm=4.75 inch

139.7 mm=5.5 inch

* We have a large variety of trailer and boat trailer axles. The axles are available in leaf spring or torsion suspension from 2,000 lbs to 1,2000 lbs capacities. What’s more, we can produce it according to customer’s requests, drawings or samples.

Trailer short shaft size needs to be customized according to customer requirements

1. who are we?

We are based in ZheJiang , China, start from 2571,sell to North America(10.00%),South America(10.00%),Southeast

Asia(10.00%),Africa(10.00%),Mid East(10.00%),Eastern Asia(10.00%),Central America(10.00%),Northern Europe(10.00%),South

Asia(10.00%),Domestic Market(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

semi trailer axles, air suspensions , chamber,wheel ,slack adjuster and other related items.

4. why should you buy from us not from other suppliers?

We have a trailer parts production more than 10 years the supply chain

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese

6.what is the certificate

At present, the company can undertake CCS, ABS, BV, GL and other certification products /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Availiable |

|---|---|

| Condition: | New |

| Axle Number: | 2 |

| Application: | Trailer |

| Certification: | ISO |

| Material: | Steel |

| Customization: |

Available

|

|

|---|

Can you explain the role of bearings in conjunction with trailer spindles in towing systems?

Trailer bearings play a critical role in conjunction with trailer spindles in towing systems. Here’s an explanation of their role:

Trailer bearings are components that facilitate the smooth rotation of the trailer wheels around the spindles. They are located within the hub assembly and provide a low-friction interface between the stationary spindle and the rotating wheel. The bearings allow the trailer wheels to rotate freely while supporting the weight of the trailer and its cargo.

The primary functions of bearings in conjunction with trailer spindles are:

- Load Support: Bearings bear the weight of the trailer and its cargo, transferring the load from the axle to the wheels. They distribute the load evenly across the spindle, preventing excessive stress on any specific area and ensuring optimal load capacity.

- Reducing Friction: Bearings minimize friction between the stationary spindle and the rotating wheel hub. By providing a smooth, low-friction interface, they allow the wheels to rotate freely with minimal resistance. This reduces energy consumption and promotes efficient towing.

- Alignment and Stability: Bearings help maintain proper alignment and stability of the trailer wheels. They ensure that the wheels rotate in a straight line and prevent wobbling or uneven tire wear. This is crucial for safe and controlled towing, as improper wheel alignment can lead to handling issues and compromised stability.

- Shock Absorption: Bearings also play a role in absorbing shocks and vibrations encountered during towing. They provide a cushioning effect, reducing the impact of bumps and irregularities on the trailer wheels. This helps improve overall ride comfort and protects the trailer and its contents from excessive jolts or vibrations.

- Lubrication: Properly lubricated bearings reduce friction and heat generation. They also help prevent premature wear and damage to the bearing surfaces. Lubrication ensures smooth operation and extends the lifespan of the bearings and the overall functionality of the towing system.

It’s important to note that trailer bearings require regular maintenance, including inspection, cleaning, and lubrication, to ensure their optimal performance and longevity. Neglecting bearing maintenance can lead to overheating, premature wear, and ultimately, bearing failure, which can result in costly repairs and unsafe towing conditions.

When selecting bearings for trailer spindles, it’s crucial to choose high-quality bearings that are appropriate for the load capacity and towing conditions. It’s recommended to follow the manufacturer’s guidelines regarding bearing specifications, lubrication intervals, and maintenance procedures to ensure proper functioning of the bearings in conjunction with the trailer spindles.

In summary, trailer bearings are essential components in towing systems that work in conjunction with trailer spindles. They support the load, reduce friction, maintain alignment and stability, absorb shocks, and require regular maintenance to ensure optimal functionality and safe towing operations.

How do trailer spindles impact the performance and safety of a towing system?

Trailer spindles play a crucial role in influencing the performance and safety of a towing system. Here’s a detailed explanation of how trailer spindles impact towing system performance and safety:

- Wheel Attachment and Stability:

Trailer spindles provide the attachment point for the trailer wheels. They secure the wheels to the trailer and ensure proper alignment and stability during towing. A well-designed and properly installed spindle contributes to the overall stability of the trailer, minimizing the risk of wheel detachment, wobbling, or excessive vibrations. This enhances the towing system’s performance and improves safety on the road.

- Load Distribution:

Trailer spindles play a crucial role in distributing the weight of the load across the trailer axle. As the load is transferred from the trailer frame to the wheels through the spindles, they help maintain proper load distribution. Balanced load distribution is vital for safe towing, as it minimizes the risk of overloading certain wheels or axles, which could lead to instability and compromised handling.

- Strength and Durability:

The strength and durability of trailer spindles directly impact the towing system’s performance and safety. Spindles should be designed and manufactured to withstand the weight and forces exerted on the trailer during towing. High-quality spindles made from robust materials, such as steel, provide the necessary strength and durability to handle the load and maintain stability. Weak or compromised spindles can lead to failures, resulting in accidents or damage to the trailer and other vehicles.

- Wheel Alignment and Tracking:

Proper wheel alignment and tracking are critical for the safe operation of a towing system. Trailer spindles play a role in maintaining the correct alignment of the wheels. Misaligned wheels can cause uneven tire wear, reduced fuel efficiency, and compromised stability during towing. Well-designed spindles ensure that the wheels are aligned correctly, promoting smooth and predictable towing performance.

- Smooth and Controlled Towing:

Trailer spindles contribute to achieving smooth and controlled towing experiences. They facilitate smooth wheel rotation, allowing the wheels to spin freely and reduce friction. Smooth rotation enhances the overall performance of the towing system, promoting better fuel efficiency, reduced wear on trailer components, and improved handling and control.

- Compatibility with Suspension System:

Trailer spindles need to work in conjunction with the trailer’s suspension system. The spindle design and specifications should be compatible with the suspension components, such as leaf springs or torsion axles. Proper compatibility ensures that the spindles can handle the movement and forces generated by the suspension system, maintaining stability and minimizing the impact of uneven or rough road surfaces.

- Compliance with Safety Standards:

Trailer spindles must meet safety standards and regulations to ensure the overall safety of the towing system. Compliance with these standards ensures that the spindles are designed, manufactured, and installed to provide the necessary strength, stability, and reliability for safe towing operations.

In summary, trailer spindles have a significant impact on the performance and safety of a towing system. They contribute to wheel attachment and stability, facilitate load distribution, provide strength and durability, influence wheel alignment and tracking, enable smooth and controlled towing, ensure compatibility with the suspension system, and comply with safety standards. Choosing high-quality spindles and ensuring proper installation and maintenance are essential for a safe and reliable towing experience.

What is a trailer spindle, and what role does it play in a trailer’s construction?

A trailer spindle is a crucial component in the construction of a trailer. It serves a vital role in supporting and facilitating the movement of the trailer’s wheels. Here’s a detailed explanation of what a trailer spindle is and its significance in a trailer’s construction:

A trailer spindle is a shaft-like component that connects the trailer axle to the wheel hub. It is typically made of high-strength steel and is responsible for supporting the weight of the trailer and facilitating the rotation of the wheels. The spindle is mounted within the wheel hub assembly and allows the wheel to rotate smoothly and securely.

The trailer spindle performs several important functions:

- Wheel Attachment: The spindle provides a secure attachment point for the trailer wheels. It is designed to fit into the wheel hub assembly and is often tapered to ensure a tight and reliable connection. The wheel is typically mounted on the spindle using lug nuts or bolts, which secure it in place.

- Load Bearing: The trailer spindle bears the weight of the trailer and its cargo. It transfers the load from the trailer’s frame and axle to the wheels, distributing the weight evenly across the axle. The spindle must be strong enough to withstand the weight and forces exerted on the wheels during trailer operation.

- Wheel Rotation: The spindle allows the trailer wheels to rotate freely. As the trailer moves, the spindle transfers the rotational force from the axle to the wheel hub, enabling the wheels to spin. This rotation is essential for the trailer’s mobility and maneuverability.

- Lubrication and Heat Dissipation: Some trailer spindles incorporate grease or oil seals and fittings to allow for lubrication. Proper lubrication reduces friction and wear between the spindle and the wheel hub, enhancing the overall performance and lifespan of the trailer’s wheels. Additionally, the spindle’s design facilitates heat dissipation, helping to prevent excessive heat buildup that can lead to component failure.

In summary, a trailer spindle is a vital component in a trailer’s construction. It serves as the connection between the axle and the wheel hub, providing a secure attachment point for the wheels and supporting the weight of the trailer. The spindle enables the wheels to rotate freely, facilitating the trailer’s mobility. It may also incorporate features for lubrication and heat dissipation to ensure proper functioning and longevity of the trailer’s wheels. Overall, the trailer spindle plays a critical role in maintaining the stability, safety, and performance of the trailer during operation.

editor by CX 2024-03-01

China manufacturer Trailer Parts Rear Axle Shaft Factory Supply Cheap Price Agriculture Axle Trailer Spindle Trailer Hubs

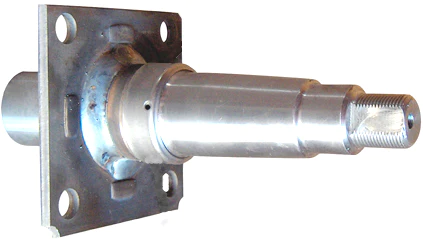

Product Description

trailer parts rear axle shaft Factory Supply Cheap Price agriculture axle Trailer spindle trailer hubs

|

item |

value |

|

Place of CHINAMFG |

China |

|

Province |

ZheJiang |

|

Model Number |

Customized Services |

|

Process |

Mainly Hot forging, Some parts with Cold forging ,die forging and Free forgin will be OK |

|

Material |

Carbon steel: CM490,A36,1045,1035 etc., Alloy steel: 40Cr, 20CrMnTi, 20CrNiMo, 42CrMo4 etc., Stainless steel, SS304,SS316 etc. |

|

Weight |

1kg – 120kg |

|

Applicable Machining Process |

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc. |

|

Machining Tolerance |

0.03mm-0.1mm |

|

Applicable Finish Surface Treatment |

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting, |

|

Testing equipment |

Supersonic inspection machine, Supersonic flaw detecting machine , physics and chemical analysis. |

|

MOQ of mass production |

1000-5000pcs |

|

Testing equipment |

Optical Spectrum Analyzer,tensile testing machine,impact testing machine,fluorescent magnetic particle detector,hardness tester,ultrasonic flaw detector..etc. |

|

Packing |

Wooden cases or according to customers’ needs |

1. who are we?

We are based in ZheJiang , China, start from 2571,sell to North America(10.00%),South America(10.00%),Southeast

Asia(10.00%),Africa(10.00%),Mid East(10.00%),Eastern Asia(10.00%),Central America(10.00%),Northern Europe(10.00%),South

Asia(10.00%),Domestic Market(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

semi trailer axles, air suspensions , chamber,wheel ,slack adjuster and other related items.

4. why should you buy from us not from other suppliers?

We have a trailer parts production more than 10 years the supply chain

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese

6.what is the certificate

At present, the company can undertake CCS, ABS, BV, GL and other certification products /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Available |

|---|---|

| Condition: | New |

| Application: | Trailer |

| Certification: | ASTM, CE, DIN, ISO |

| Material: | Steel |

| Transport Package: | Customized |

| Customization: |

Available

|

|

|---|

Can you provide insights into the importance of proper installation and alignment of trailer spindles?

Proper installation and alignment of trailer spindles are of utmost importance for the safe and efficient operation of trailers. Here’s a detailed explanation:

1. Safety: Ensuring the proper installation and alignment of trailer spindles is crucial for maintaining safe towing conditions. When spindles are installed correctly, they provide structural integrity and stability to the trailer. Proper alignment ensures that the wheels track straight and true, reducing the risk of swaying, fishtailing, or loss of control while towing. Incorrect installation or misalignment can lead to handling issues, increased risk of accidents, and compromised safety for both the driver and other road users.

2. Load Distribution: Properly installed and aligned trailer spindles contribute to effective load distribution. They help evenly distribute the weight of the trailer and its cargo across the axles and wheels. This balanced distribution minimizes excessive stress on specific components, such as tires, suspension, and bearings, ensuring their optimal performance and longevity. Improper installation or misalignment can lead to uneven weight distribution, which may result in premature wear, tire blowouts, or other mechanical failures.

3. Tire Wear: Correct spindle installation and alignment play a significant role in reducing tire wear. When the spindles are aligned properly, the trailer wheels track in a straight line, resulting in even tire wear. Misalignment, on the other hand, can cause irregular tire wear patterns, such as cupping or feathering, which decrease tire lifespan and performance. Proper alignment of spindles helps to maximize tire longevity and maintain optimal traction and handling characteristics.

4. Bearing Performance: Trailer spindles directly impact the performance and lifespan of the bearings. Proper installation ensures that the spindles are securely attached to the trailer frame, providing a stable platform for the bearings. Misalignment or inadequate installation can cause excessive stress on the bearings, leading to premature wear, overheating, and potential bearing failure. Proper alignment and installation of spindles help to maintain the bearings’ integrity, ensuring smooth rotation, reduced friction, and optimal load support.

5. Fuel Efficiency: Properly installed and aligned spindles can contribute to improved fuel efficiency. When the trailer wheels are properly aligned, they experience reduced rolling resistance, resulting in lower energy consumption and improved fuel economy. Misalignment can cause increased rolling resistance, leading to higher fuel consumption during towing.

6. Handling and Stability: Correct spindle installation and alignment contribute to the overall handling and stability of the trailer. Proper alignment ensures that the trailer tracks in a straight line, allowing for predictable and controlled towing. Misalignment can cause the trailer to pull to one side, leading to unstable towing conditions, reduced maneuverability, and potential loss of control.

7. Longevity and Cost Savings: Proper installation and alignment of trailer spindles contribute to the longevity of various trailer components, including tires, bearings, suspension systems, and axles. By minimizing excessive wear, stress, and premature failures, proper alignment and installation help to extend the lifespan of these components. This leads to cost savings in terms of reduced maintenance, repairs, and replacement of parts.

It’s important to follow the manufacturer’s guidelines and recommendations for the installation and alignment of trailer spindles. This may involve using proper tools, torque specifications, and alignment procedures. Seeking professional assistance or consulting with experienced professionals can also ensure accurate installation and alignment, especially when dealing with complex trailer configurations or modifications.

Overall, proper installation and alignment of trailer spindles are vital for safety, load distribution, tire wear, bearing performance, fuel efficiency, handling, stability, longevity, and cost savings. By paying attention to these critical aspects, trailer owners can optimize the performance and reliability of their towing systems.

What advantages do certain types of trailer spindles offer compared to others?

Trailer spindles come in various types, and each type offers unique advantages compared to others. Here’s a detailed explanation:

- Straight Spindles:

Straight spindles are the most common type and offer several advantages:

- Cost-Effective: Straight spindles are relatively simple in design and construction, making them cost-effective compared to other types.

- Wide Availability: Straight spindles are widely available, making them easy to find and replace if needed.

- Easy Maintenance: Straight spindles are relatively easy to maintain and service, requiring fewer specialized tools or techniques.

- Tapered Spindles:

Tapered spindles provide their own set of advantages:

- Increased Load Capacity: Tapered spindles are designed to handle higher load capacities compared to straight spindles of similar size. The tapered shape enhances their strength and load-bearing capabilities.

- Better Alignment: Tapered spindles offer improved wheel alignment as they allow for precise fitment of the wheel hub assembly. This helps in maintaining proper tracking and reduces tire wear.

- Enhanced Stability: The taper design of these spindles contributes to enhanced stability during towing, reducing the risk of wheel wobbling or vibrations.

- Drop Spindles:

Drop spindles offer specific advantages for certain trailer applications:

- Lowered Trailer Height: Drop spindles are designed to lower the trailer’s ride height, allowing for easier loading and unloading of cargo or equipment.

- Improved Ground Clearance: By lowering the trailer height, drop spindles can also improve ground clearance, reducing the risk of bottoming out on uneven terrain.

- Enhanced Aerodynamics: The lower trailer height achieved with drop spindles can improve aerodynamics, leading to potential fuel efficiency gains.

- Brake Spindles:

Brake spindles offer advantages when used with trailer braking systems:

- Integrated Braking: Brake spindles are designed to accommodate brake assemblies and provide a mounting point for the brake components, allowing for integrated braking systems.

- Improved Stopping Power: Brake spindles, when used with appropriate brake systems, enhance the trailer’s stopping power, improving overall safety during towing.

- Controlled Braking: Brake spindles provide better control and modulation of braking forces, allowing for smoother and more controlled stops.

It’s important to note that the advantages of certain types of trailer spindles may be more relevant to specific trailer applications or towing requirements. Consideration should also be given to factors such as load capacity, compatibility with other trailer components, and manufacturer recommendations when selecting the appropriate spindle type for a given application.

In summary, certain types of trailer spindles offer advantages over others. Straight spindles are cost-effective, widely available, and easy to maintain. Tapered spindles provide increased load capacity, better alignment, and enhanced stability. Drop spindles lower the trailer height, improve ground clearance, and enhance aerodynamics. Brake spindles offer integrated braking, improved stopping power, and controlled braking. Understanding the advantages of different spindle types helps in selecting the most suitable option based on specific trailer requirements and towing needs.

In what types of trailers are spindles commonly used, and how do they vary?

Trailer spindles are commonly used in various types of trailers, and their design can vary depending on the specific trailer application. Here’s a detailed explanation of the types of trailers where spindles are commonly used and how they can vary:

- Utility Trailers:

Utility trailers, including flatbed trailers, equipment trailers, and landscape trailers, often utilize spindles. These trailers are commonly used for transporting a wide range of goods and equipment. The spindles used in utility trailers can vary in size, load-bearing capacity, and configuration to accommodate different trailer sizes and weight requirements.

- Boat Trailers:

Boat trailers are designed to transport boats of various sizes and types. Spindles used in boat trailers are typically designed to withstand corrosive environments due to exposure to water and may incorporate special coatings or materials to enhance durability. They can also have unique features such as bearing buddies or seals to provide additional protection against water intrusion and lubrication.

- RV and Camper Trailers:

Recreational vehicles (RVs) and camper trailers often employ spindles to support the wheels and axles. These spindles are designed to handle the weight of the living quarters and amenities found in these trailers. They may have specific load-bearing capacities and configurations to meet the requirements of different RV and camper trailer sizes and designs.

- Horse Trailers:

Horse trailers are used for transporting horses and typically feature spindles to support the wheels. These spindles are designed to withstand the additional dynamic loads and stresses associated with transporting live animals. They may have features such as grease fittings or sealed bearings for ease of maintenance and durability.

- Cargo Trailers:

Cargo trailers are used for transporting goods and merchandise. They often incorporate spindles to support the wheels and accommodate the weight of the cargo. The design of spindles used in cargo trailers can vary depending on the trailer’s size, load capacity, and intended use.

- Travel Trailers and Caravans:

Travel trailers and caravans are towable living quarters designed for recreational travel. They utilize spindles to support the wheels and axles. The spindles used in travel trailers and caravans can vary depending on the trailer’s size, weight, and specific features. They may incorporate features for ease of maintenance and durability, such as grease fittings or sealed bearings.

In summary, spindles are commonly used in a wide range of trailers, including utility trailers, boat trailers, RV and camper trailers, horse trailers, cargo trailers, and travel trailers. The design of spindles can vary based on the specific trailer application, including size, weight capacity, load-bearing requirements, and environmental considerations. These variations ensure that the spindles are well-suited to the demands of different trailer types and provide reliable support for the wheels and axles during towing.

editor by CX 2024-02-29

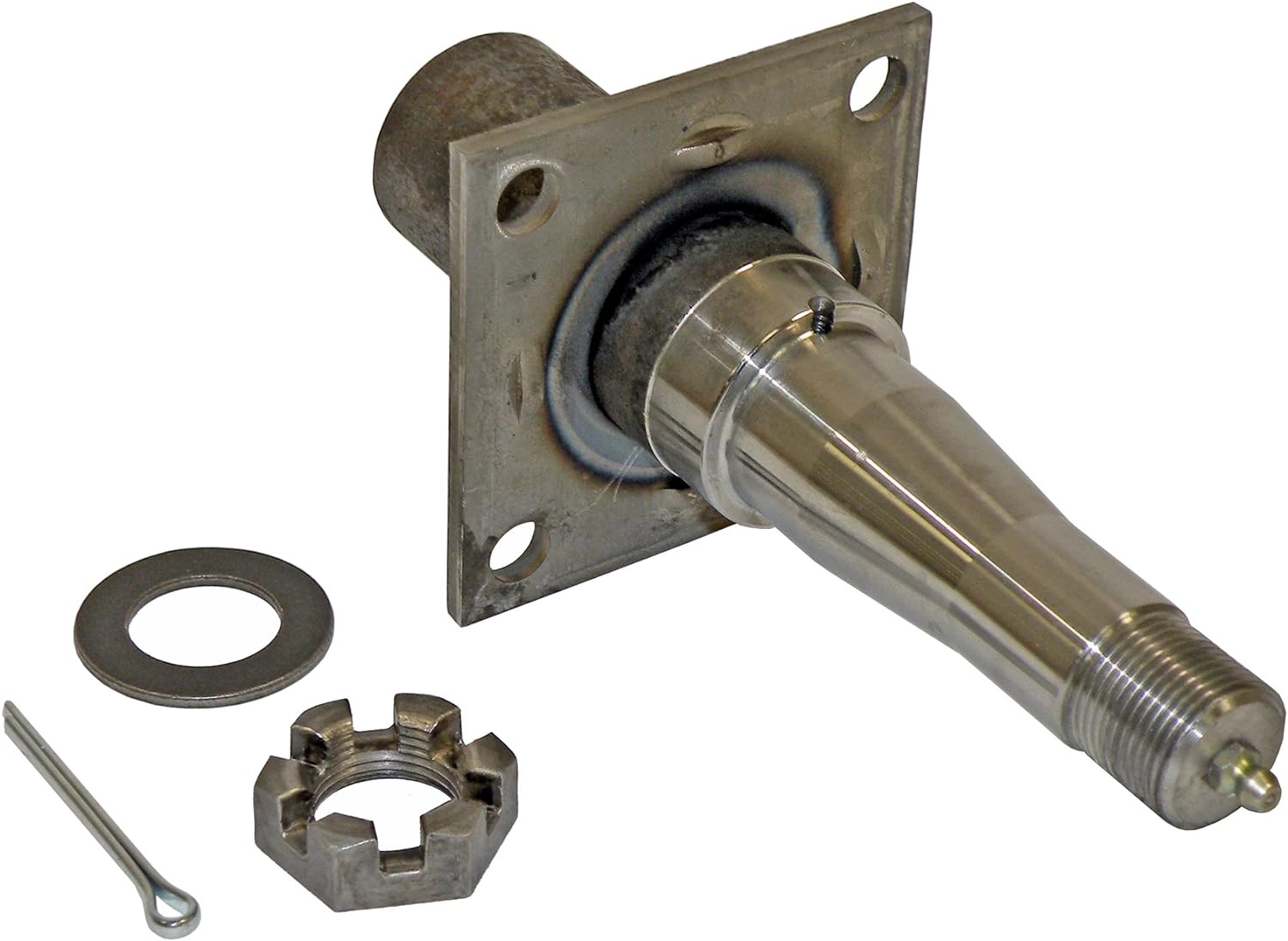

China OEM Custom Factory Forged Steel Trailer Shaft Axle Spindle

Product Description

Forging shaft/spindle/roll/roller/axle

Product Disply

Inspection

| Specification | customer’s drawings |

| Material | cast iron, Grey iron, ductile iron, carbon steel, low alloy steel, tool steel, steel, stainless steel, brass, copper, aluminum alloy, zinc etc |

| Process | Sand casting,Coated sand casting,Shell mold casting,Lost foam casting ,V- process,Centrifugal casting,Ceramic Casting,machining,free forging,die forging,pressure forming ,roll forging,precision forging,etc. |

| casting | sand casting,precision casting,centrifugal casting,lost foam casting,die casting,gravity casting |

| machine | lathe,CNC,drilling machine,milling machine,boring machine,planting machine,machining center etc |

| Application | Automobile, agricultural machinery, furniture, construction, home appliances, electronics. |

| surface treatment | powder coating,painting,spraying,electric galvanization,coating,zinc phosphide,impregnation,painting,spray paint,black and blue oxide coating, |

| Inspection equipment | Profile projector,Rockwell hardness tester,Vickers hardness tester roughness tester,air gage,concentricity tester,universial microscope,CMM,digital caliper and etc. |

| Production Usage | Auto parts,train parts,mining accessories,engineering machinery parts,valves,pipe fittings,construction machinery and furniture accessories,agricultural machinery parts |

| Remark | (1)Any RFQ, Please feel free to send your drawings(CAD/PDF)for your quotation. (2)All parts are not in stock, customized only! |

FAQ

Q: What do I need for offering a quote ?

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.) ,quantity, application or samples. Then we will quote the best price within 24h.

Q: What is your MOQ?

A: MOQ depends on our client’s needs, besides,we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to meet customers’ requirement by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A.: T/T, L/C, Escrow, Paypal, western union, etc.

Q: Is it possible to know how is my product going on without visiting your company?

A: We will offer a detailed products schedule and send weekly reports with digital pictures and videos which show the machining progress.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Processing Object: | Metal |

|---|---|

| Molding Style: | Forging |

| Molding Technics: | Gravity Casting |

| Application: | Machinery Parts |

| Material: | Steel |

| Heat Treatment: | Annealing |

| Customization: |

Available

|

|

|---|

Are there innovations or advancements in trailer spindle technology that have emerged recently?

Yes, there have been notable innovations and advancements in trailer spindle technology that have emerged recently. Here’s a detailed explanation:

Trailer spindle technology has continued to evolve to improve the performance, durability, and safety of trailers. Some of the recent innovations and advancements include:

- Sealed Bearing Systems: Sealed bearing systems have become increasingly popular in trailer spindle technology. These systems feature integrated seals that provide enhanced protection against contaminants such as dirt, water, and debris. The sealed design helps to prolong the life of the bearings by reducing the risk of premature wear and damage. It also minimizes maintenance requirements by eliminating the need for regular bearing re-greasing.

- Improved Bearing Materials: Recent advancements have led to the development of advanced bearing materials for trailer spindles. Materials such as ceramic and advanced polymers offer superior strength, corrosion resistance, and durability compared to traditional steel bearings. These advanced bearing materials contribute to extended bearing life, reduced friction, and improved overall performance of the trailer spindles.

- High-Strength Spindle Construction: Manufacturers have been focusing on improving the strength and durability of trailer spindles. This includes the use of high-strength materials such as forged steel or alloy steel in the construction of spindles. These materials provide increased load capacity, enhanced resistance to bending or deformation, and improved structural integrity, ensuring reliable and safe towing operations.

- Intelligent Monitoring Systems: Some advancements in trailer spindle technology have introduced intelligent monitoring systems. These systems utilize sensors and advanced electronics to monitor spindle performance in real-time. They can detect abnormalities such as excessive heat, vibration, or bearing wear and provide early warning alerts to the operator. Intelligent monitoring systems help prevent potential failures, reduce downtime, and enhance overall safety during towing.

- Enhanced Corrosion Resistance: With a focus on improving the longevity of trailer spindles, advancements have been made in enhancing corrosion resistance. This includes the use of specialized coatings, surface treatments, or materials that provide superior protection against corrosion caused by factors like moisture, salt, or harsh environmental conditions. Enhanced corrosion resistance helps to prolong the lifespan of the spindles and ensures their optimal functionality over an extended period.

These recent innovations and advancements in trailer spindle technology have contributed to improved performance, increased durability, and enhanced safety in towing systems. They address common challenges such as bearing maintenance, corrosion, load capacity, and monitoring, providing trailer owners with more reliable and efficient options for their towing needs.

It’s important to note that the availability and implementation of these advancements may vary among different manufacturers and models of trailers. When considering the latest innovations in trailer spindle technology, it’s advisable to consult with manufacturers, industry experts, or trusted suppliers to explore the specific features and benefits offered by different spindle systems.

How do trailer spindles impact the performance and safety of a towing system?

Trailer spindles play a crucial role in influencing the performance and safety of a towing system. Here’s a detailed explanation of how trailer spindles impact towing system performance and safety:

- Wheel Attachment and Stability:

Trailer spindles provide the attachment point for the trailer wheels. They secure the wheels to the trailer and ensure proper alignment and stability during towing. A well-designed and properly installed spindle contributes to the overall stability of the trailer, minimizing the risk of wheel detachment, wobbling, or excessive vibrations. This enhances the towing system’s performance and improves safety on the road.

- Load Distribution:

Trailer spindles play a crucial role in distributing the weight of the load across the trailer axle. As the load is transferred from the trailer frame to the wheels through the spindles, they help maintain proper load distribution. Balanced load distribution is vital for safe towing, as it minimizes the risk of overloading certain wheels or axles, which could lead to instability and compromised handling.

- Strength and Durability:

The strength and durability of trailer spindles directly impact the towing system’s performance and safety. Spindles should be designed and manufactured to withstand the weight and forces exerted on the trailer during towing. High-quality spindles made from robust materials, such as steel, provide the necessary strength and durability to handle the load and maintain stability. Weak or compromised spindles can lead to failures, resulting in accidents or damage to the trailer and other vehicles.

- Wheel Alignment and Tracking:

Proper wheel alignment and tracking are critical for the safe operation of a towing system. Trailer spindles play a role in maintaining the correct alignment of the wheels. Misaligned wheels can cause uneven tire wear, reduced fuel efficiency, and compromised stability during towing. Well-designed spindles ensure that the wheels are aligned correctly, promoting smooth and predictable towing performance.

- Smooth and Controlled Towing:

Trailer spindles contribute to achieving smooth and controlled towing experiences. They facilitate smooth wheel rotation, allowing the wheels to spin freely and reduce friction. Smooth rotation enhances the overall performance of the towing system, promoting better fuel efficiency, reduced wear on trailer components, and improved handling and control.

- Compatibility with Suspension System:

Trailer spindles need to work in conjunction with the trailer’s suspension system. The spindle design and specifications should be compatible with the suspension components, such as leaf springs or torsion axles. Proper compatibility ensures that the spindles can handle the movement and forces generated by the suspension system, maintaining stability and minimizing the impact of uneven or rough road surfaces.

- Compliance with Safety Standards:

Trailer spindles must meet safety standards and regulations to ensure the overall safety of the towing system. Compliance with these standards ensures that the spindles are designed, manufactured, and installed to provide the necessary strength, stability, and reliability for safe towing operations.

In summary, trailer spindles have a significant impact on the performance and safety of a towing system. They contribute to wheel attachment and stability, facilitate load distribution, provide strength and durability, influence wheel alignment and tracking, enable smooth and controlled towing, ensure compatibility with the suspension system, and comply with safety standards. Choosing high-quality spindles and ensuring proper installation and maintenance are essential for a safe and reliable towing experience.

What is a trailer spindle, and what role does it play in a trailer’s construction?

A trailer spindle is a crucial component in the construction of a trailer. It serves a vital role in supporting and facilitating the movement of the trailer’s wheels. Here’s a detailed explanation of what a trailer spindle is and its significance in a trailer’s construction:

A trailer spindle is a shaft-like component that connects the trailer axle to the wheel hub. It is typically made of high-strength steel and is responsible for supporting the weight of the trailer and facilitating the rotation of the wheels. The spindle is mounted within the wheel hub assembly and allows the wheel to rotate smoothly and securely.

The trailer spindle performs several important functions:

- Wheel Attachment: The spindle provides a secure attachment point for the trailer wheels. It is designed to fit into the wheel hub assembly and is often tapered to ensure a tight and reliable connection. The wheel is typically mounted on the spindle using lug nuts or bolts, which secure it in place.

- Load Bearing: The trailer spindle bears the weight of the trailer and its cargo. It transfers the load from the trailer’s frame and axle to the wheels, distributing the weight evenly across the axle. The spindle must be strong enough to withstand the weight and forces exerted on the wheels during trailer operation.

- Wheel Rotation: The spindle allows the trailer wheels to rotate freely. As the trailer moves, the spindle transfers the rotational force from the axle to the wheel hub, enabling the wheels to spin. This rotation is essential for the trailer’s mobility and maneuverability.

- Lubrication and Heat Dissipation: Some trailer spindles incorporate grease or oil seals and fittings to allow for lubrication. Proper lubrication reduces friction and wear between the spindle and the wheel hub, enhancing the overall performance and lifespan of the trailer’s wheels. Additionally, the spindle’s design facilitates heat dissipation, helping to prevent excessive heat buildup that can lead to component failure.

In summary, a trailer spindle is a vital component in a trailer’s construction. It serves as the connection between the axle and the wheel hub, providing a secure attachment point for the wheels and supporting the weight of the trailer. The spindle enables the wheels to rotate freely, facilitating the trailer’s mobility. It may also incorporate features for lubrication and heat dissipation to ensure proper functioning and longevity of the trailer’s wheels. Overall, the trailer spindle plays a critical role in maintaining the stability, safety, and performance of the trailer during operation.

editor by CX 2024-01-16

China Manufacturers undertake BT50BT40BT30 CNC spindle customized Spline shaft Power shaft ER extension rod shaft drive shaft coupler

Condition: New

Relevant Industries: Creating Material Retailers, Industrial 220V Oil-free of charge Movable Blowing Dust Air Pump Paint Spray Gun Little 6 175710015 935-501 Strength & Mining

Fat (KG): 1

Showroom Area: None

Video outgoing-inspection: Offered

Equipment Examination Report: Not Accessible

Advertising and marketing Type: Common Merchandise

Warranty: Unavailable

Main Components: Bearing

Packaging Specifics: Carton or foam wrapping

Port: HangZhou

Packaging & Delivery

Organization Information

FAQ

Types of Splines

There are four types of splines: Involute, Parallel key, helical, and ball. Learn about their characteristics. And, if you’re not sure what they are, you can always request a quotation. These splines are commonly used for building special machinery, repair jobs, and other applications. The CZPT Manufacturing Company manufactures these shafts. It is a specialty manufacturer and we welcome your business.

Involute splines

The involute spline provides a more rigid and durable structure, and is available in a variety of diameters and spline counts. Generally, steel, carbon steel, or titanium are used as raw materials. Other materials, such as carbon fiber, may be suitable. However, titanium can be difficult to produce, so some manufacturers make splines using other constituents.

When splines are used in shafts, they prevent parts from separating during operation. These features make them an ideal choice for securing mechanical assemblies. Splines with inward-curving grooves do not have sharp corners and are therefore less likely to break or separate while they are in operation. These properties help them to withstand high-speed operations, such as braking, accelerating, and reversing.

A male spline is fitted with an externally-oriented face, and a female spline is inserted through the center. The teeth of the male spline typically have chamfered tips to provide clearance with the transition area. The radii and width of the teeth of a male spline are typically larger than those of a female spline. These specifications are specified in ANSI or DIN design manuals.

The effective tooth thickness of a spline depends on the involute profile error and the lead error. Also, the spacing of the spline teeth and keyways can affect the effective tooth thickness. Involute splines in a splined shaft are designed so that at least 25 percent of the spline teeth engage during coupling, which results in a uniform distribution of load and wear on the spline.

Parallel key splines

A parallel splined shaft has a helix of equal-sized grooves around its circumference. These grooves are generally parallel or involute. Splines minimize stress concentrations in stationary joints and allow linear and rotary motion. Splines may be cut or cold-rolled. Cold-rolled splines have more strength than cut spines and are often used in applications that require high strength, accuracy, and a smooth surface.

A parallel key splined shaft features grooves and keys that are parallel to the axis of the shaft. This design is best suited for applications where load bearing is a primary concern and a smooth motion is needed. A parallel key splined shaft can be made from alloy steels, which are iron-based alloys that may also contain chromium, nickel, molybdenum, copper, or other alloying materials.

A splined shaft can be used to transmit torque and provide anti-rotation when operating as a linear guide. These shafts have square profiles that match up with grooves in a mating piece and transmit torque and rotation. They can also be easily changed in length, and are commonly used in aerospace. Its reliability and fatigue life make it an excellent choice for many applications.

The main difference between a parallel key splined shaft and a keyed shaft is that the former offers more flexibility. They lack slots, which reduce torque-transmitting capacity. Splines offer equal load distribution along the gear teeth, which translates into a longer fatigue life for the shaft. In agricultural applications, shaft life is essential. Agricultural equipment, for example, requires the ability to function at high speeds for extended periods of time.

Involute helical splines

Involute splines are a common design for splined shafts. They are the most commonly used type of splined shaft and feature equal spacing among their teeth. The teeth of this design are also shorter than those of the parallel spline shaft, reducing stress concentration. These splines can be used to transmit power to floating or permanently fixed gears, and reduce stress concentrations in the stationary joint. Involute splines are the most common type of splined shaft, and are widely used for a variety of applications in automotive, machine tools, and more.

Involute helical spline shafts are ideal for applications involving axial motion and rotation. They allow for face coupling engagement and disengagement. This design also allows for a larger diameter than a parallel spline shaft. The result is a highly efficient gearbox. Besides being durable, splines can also be used for other applications involving torque and energy transfer.

A new statistical model can be used to determine the number of teeth that engage for a given load. These splines are characterized by a tight fit at the major diameters, thereby transferring concentricity from the shaft to the female spline. A male spline has chamfered tips for clearance with the transition area. ANSI and DIN design manuals specify the different classes of fit.

The design of involute helical splines is similar to that of gears, and their ridges or teeth are matched with the corresponding grooves in a mating piece. It enables torque and rotation to be transferred to a mate piece while maintaining alignment of the two components. Different types of splines are used in different applications. Different splines can have different levels of tooth height.

Involute ball splines

When splines are used, they allow the shaft and hub to engage evenly over the shaft’s entire circumference. Because the teeth are evenly spaced, the load that they can transfer is uniform and their position is always the same regardless of shaft length. Whether the shaft is used to transmit torque or to transmit power, splines are a great choice. They provide maximum strength and allow for linear or rotary motion.

There are three basic types of splines: helical, crown, and ball. Crown splines feature equally spaced grooves. Crown splines feature involute sides and parallel sides. Helical splines use involute teeth and are often used in small diameter shafts. Ball splines contain a ball bearing inside the splined shaft to facilitate rotary motion and minimize stress concentration in stationary joints.

The two types of splines are classified under the ANSI classes of fit. Fillet root splines have teeth that mesh along the longitudinal axis of rotation. Flat root splines have similar teeth, but are intended to optimize strength for short-term use. Both types of splines are important for ensuring the shaft aligns properly and is not misaligned.

The friction coefficient of the hub is a complex process. When the hub is off-center, the center moves in predictable but irregular motion. Moreover, when the shaft is centered, the center may oscillate between being centered and being off-center. To compensate for this, the torque must be adequate to keep the shaft in its axis during all rotation angles. While straight-sided splines provide similar centering, they have lower misalignment load factors.

Keyed shafts

Essentially, splined shafts have teeth or ridges that fit together to transfer torque. Because splines are not as tall as involute gears, they offer uniform torque transfer. Additionally, they provide the opportunity for torque and rotational changes and improve wear resistance. In addition to their durability, splined shafts are popular in the aerospace industry and provide increased reliability and fatigue life.

Keyed shafts are available in different materials, lengths, and diameters. When used in high-power drive applications, they offer higher torque and rotational speeds. The higher torque they produce helps them deliver power to the gearbox. However, they are not as durable as splined shafts, which is why the latter is usually preferred in these applications. And while they’re more expensive, they’re equally effective when it comes to torque delivery.

Parallel keyed shafts have separate profiles and ridges and are used in applications requiring accuracy and precision. Keyed shafts with rolled splines are 35% stronger than cut splines and are used where precision is essential. These splines also have a smooth finish, which can make them a good choice for precision applications. They also work well with gears and other mechanical systems that require accurate torque transfer.

Carbon steel is another material used for splined shafts. Carbon steel is known for its malleability, and its shallow carbon content helps create reliable motion. However, if you’re looking for something more durable, consider ferrous steel. This type contains metals such as nickel, chromium, and molybdenum. And it’s important to remember that carbon steel is not the only material to consider.

editor by czh 2023-02-19

China Custom Precision Engine Shafts Supplier Machining Stainless Carbon Linear Flexible Spline Motor Spindle Axle Steel Shaft drive shaft coupler

Issue: New

Guarantee: 1.5 many years

Applicable Industries: Garment Stores, Developing Material Retailers, Production Plant, Machinery Mend Stores, Foods & Beverage Manufacturing facility, Farms, Retail, Printing Stores, Design works , Strength & Mining, Foodstuff & Beverage Retailers, Advertising and marketing Company, Other, Other

Fat (KG): 15

Showroom Area: None

Video clip outgoing-inspection: Presented

Machinery Check Report: Provided

Advertising and marketing Variety: New Product 2571

Warranty of main parts: Not Accessible

Main Components: bearing,shaft, bearing,shaft

Composition: Spline

Content: Steel or as customer’s demand from customers, Racing Motorbike Transmissions Motorcycle Sprocket and Chain Set for CFMOTO 250NK 250SR NK250 SR250(40T 14T 520H X-Ring) AISI 4140, 40Cr, Carbon Metal,Aluminium,Brass,forty five# Metal

Coatings: NICKEL

Torque Ability: 2385N.M, 2385N.M

Item title: Spline Shaft

Specification: according to customers’ drawings

Processing Sort: normalize,tempering,quenching,anneal,mood

Floor Treatment method: High Sharpening

Certificate: ISO9001

Package deal: Picket Box

Packaging Information: Picket box or as customer’s need

Port: HangZhou,HangZhou

Business Profile Specification

| item | Spline Shaft |

| Warranty | 1.5 several years |

| Applicable Industries | Hotels, Garment Retailers, Developing Materials Retailers, Producing Plant, Machinery Repair Retailers, Foods & Chicago pneumatic screw air compressor 7.5 kw 7 8 10 13 bar industrial rotary air-compressors machine for CPN 10 CPN 10 TM Beverage Manufacturing unit, Farms, Cafe, Home Use, Retail, Foods Store, Printing Stores, Design functions , Vitality & Mining, Foods & Beverage Outlets, Other, Advertising and marketing Company |

| Weight (KG) | 15 |

| Showroom Area | None |

| Video outgoing-inspection | Provided |

| Machinery Take a look at Report | Provided |

| Marketing Variety | New Merchandise 2571 |

| Warranty of main factors | Not Offered |

| Core Elements | bearing,shaft |

| Structure | Spline |

| Material | AISI 4140, 40Cr, Carbon Metal, ZL50 26B0571 puitre yut for CLG856 CZPT wheel loaderHigh top quality add-ons drive shaft help 26B0571 for loader CLG856 Aluminium,Brass,forty five# Steel |

| Coatings | NICKEL |

| Torque Capability | 2385N.M |

| Place of Origin | ZheJiang ,China |

| Brand Identify | HangZhoug |

| Product name | Spline Shaft |

| Specification | according to customers’ drawings |

| Material | AISI 4140, 40Cr, Carbon Steel,Aluminium,Brass,45# Steel |

| Core Components | bearing,shaft |

| Processing Variety | normalize,tempering,quenching,anneal,mood |

| Surface Treatment method | High Sharpening |

| Torque Capacity | 2385N.M |

| Certificate | ISO9001 |

| Package | Wooden Box |

| Place of Origin | ZheJiang ,China |

How to Calculate Stiffness, Centering Force, Wear and Fatigue Failure of Spline Couplings

There are various types of spline couplings. These couplings have several important properties. These properties are: Stiffness, Involute splines, Misalignment, Wear and fatigue failure. To understand how these characteristics relate to spline couplings, read this article. It will give you the necessary knowledge to determine which type of coupling best suits your needs. Keeping in mind that spline couplings are usually spherical in shape, they are made of steel.

Involute splines

An effective side interference condition minimizes gear misalignment. When two splines are coupled with no spline misalignment, the maximum tensile root stress shifts to the left by five mm. A linear lead variation, which results from multiple connections along the length of the spline contact, increases the effective clearance or interference by a given percentage. This type of misalignment is undesirable for coupling high-speed equipment.

Involute splines are often used in gearboxes. These splines transmit high torque, and are better able to distribute load among multiple teeth throughout the coupling circumference. The involute profile and lead errors are related to the spacing between spline teeth and keyways. For coupling applications, industry practices use splines with 25 to fifty-percent of spline teeth engaged. This load distribution is more uniform than that of conventional single-key couplings.

To determine the optimal tooth engagement for an involved spline coupling, Xiangzhen Xue and colleagues used a computer model to simulate the stress applied to the splines. The results from this study showed that a “permissible” Ruiz parameter should be used in coupling. By predicting the amount of wear and tear on a crowned spline, the researchers could accurately predict how much damage the components will sustain during the coupling process.

There are several ways to determine the optimal pressure angle for an involute spline. Involute splines are commonly measured using a pressure angle of 30 degrees. Similar to gears, involute splines are typically tested through a measurement over pins. This involves inserting specific-sized wires between gear teeth and measuring the distance between them. This method can tell whether the gear has a proper tooth profile.

The spline system shown in Figure 1 illustrates a vibration model. This simulation allows the user to understand how involute splines are used in coupling. The vibration model shows four concentrated mass blocks that represent the prime mover, the internal spline, and the load. It is important to note that the meshing deformation function represents the forces acting on these three components.

Stiffness of coupling

The calculation of stiffness of a spline coupling involves the measurement of its tooth engagement. In the following, we analyze the stiffness of a spline coupling with various types of teeth using two different methods. Direct inversion and blockwise inversion both reduce CPU time for stiffness calculation. However, they require evaluation submatrices. Here, we discuss the differences between these two methods.

The analytical model for spline couplings is derived in the second section. In the third section, the calculation process is explained in detail. We then validate this model against the FE method. Finally, we discuss the influence of stiffness nonlinearity on the rotor dynamics. Finally, we discuss the advantages and disadvantages of each method. We present a simple yet effective method for estimating the lateral stiffness of spline couplings.

The numerical calculation of the spline coupling is based on the semi-analytical spline load distribution model. This method involves refined contact grids and updating the compliance matrix at each iteration. Hence, it consumes significant computational time. Further, it is difficult to apply this method to the dynamic analysis of a rotor. This method has its own limitations and should be used only when the spline coupling is fully investigated.

The meshing force is the force generated by a misaligned spline coupling. It is related to the spline thickness and the transmitting torque of the rotor. The meshing force is also related to the dynamic vibration displacement. The result obtained from the meshing force analysis is given in Figures 7, 8, and 9.

The analysis presented in this paper aims to investigate the stiffness of spline couplings with a misaligned spline. Although the results of previous studies were accurate, some issues remained. For example, the misalignment of the spline may cause contact damages. The aim of this article is to investigate the problems associated with misaligned spline couplings and propose an analytical approach for estimating the contact pressure in a spline connection. We also compare our results to those obtained by pure numerical approaches.

Misalignment

To determine the centering force, the effective pressure angle must be known. Using the effective pressure angle, the centering force is calculated based on the maximum axial and radial loads and updated Dudley misalignment factors. The centering force is the maximum axial force that can be transmitted by friction. Several published misalignment factors are also included in the calculation. A new method is presented in this paper that considers the cam effect in the normal force.

In this new method, the stiffness along the spline joint can be integrated to obtain a global stiffness that is applicable to torsional vibration analysis. The stiffness of bearings can also be calculated at given levels of misalignment, allowing for accurate estimation of bearing dimensions. It is advisable to check the stiffness of bearings at all times to ensure that they are properly sized and aligned.

A misalignment in a spline coupling can result in wear or even failure. This is caused by an incorrectly aligned pitch profile. This problem is often overlooked, as the teeth are in contact throughout the involute profile. This causes the load to not be evenly distributed along the contact line. Consequently, it is important to consider the effect of misalignment on the contact force on the teeth of the spline coupling.

The centre of the male spline in Figure 2 is superposed on the female spline. The alignment meshing distances are also identical. Hence, the meshing force curves will change according to the dynamic vibration displacement. It is necessary to know the parameters of a spline coupling before implementing it. In this paper, the model for misalignment is presented for spline couplings and the related parameters.

Using a self-made spline coupling test rig, the effects of misalignment on a spline coupling are studied. In contrast to the typical spline coupling, misalignment in a spline coupling causes fretting wear at a specific position on the tooth surface. This is a leading cause of failure in these types of couplings.

Wear and fatigue failure

The failure of a spline coupling due to wear and fatigue is determined by the first occurrence of tooth wear and shaft misalignment. Standard design methods do not account for wear damage and assess the fatigue life with big approximations. Experimental investigations have been conducted to assess wear and fatigue damage in spline couplings. The tests were conducted on a dedicated test rig and special device connected to a standard fatigue machine. The working parameters such as torque, misalignment angle, and axial distance have been varied in order to measure fatigue damage. Over dimensioning has also been assessed.

During fatigue and wear, mechanical sliding takes place between the external and internal splines and results in catastrophic failure. The lack of literature on the wear and fatigue of spline couplings in aero-engines may be due to the lack of data on the coupling’s application. Wear and fatigue failure in splines depends on a number of factors, including the material pair, geometry, and lubrication conditions.

The analysis of spline couplings shows that over-dimensioning is common and leads to different damages in the system. Some of the major damages are wear, fretting, corrosion, and teeth fatigue. Noise problems have also been observed in industrial settings. However, it is difficult to evaluate the contact behavior of spline couplings, and numerical simulations are often hampered by the use of specific codes and the boundary element method.

The failure of a spline gear coupling was caused by fatigue, and the fracture initiated at the bottom corner radius of the keyway. The keyway and splines had been overloaded beyond their yield strength, and significant yielding was observed in the spline gear teeth. A fracture ring of non-standard alloy steel exhibited a sharp corner radius, which was a significant stress raiser.

Several components were studied to determine their life span. These components include the spline shaft, the sealing bolt, and the graphite ring. Each of these components has its own set of design parameters. However, there are similarities in the distributions of these components. Wear and fatigue failure of spline couplings can be attributed to a combination of the three factors. A failure mode is often defined as a non-linear distribution of stresses and strains.

editor by czh 2023-02-16

China OEM China Supplier Carbon Steel Spindle Shaft with Free Design Custom

Product Description

China supplier carbon steel spindle shaft

Product Description

stainless steel axle spindle,trailer axle spindle shaft,metal spindle

1. Product Description of shaft,axis, axle, spindle by cnc machining ,also which can be called CNC

Machining Parts,CNC Lathe Parts, CNC Machined Part, turning parts, milling parts.

Process:CNC turning,CNC milling,CNC grinding;CNC lathe machining,CNC boring;CNC drilling,surface

treatment

2. Manufacture Process

Design confirm ,samples purchase, material blanking ,machininig ,surface treatment, Inspection,

assemblying, products’ Packing

Material: Stainless steel, steel , tools steel , Aluminium and other metal round bar.

Surface treatment: Anodized, plated , polished, grinding, black oxidating, passivation and

other surface treatment.

3. Advantages of products

Competitive price with high quality. over 15 sets automatic lathe, drilling, cutting etc.

Customized size and spec /OEM available.

4. Applications of our products are used in auto parts, aerospace,railway

train ,communication, petroleum , marining, engineering and other machinery industries etc.

Products show

Types of Splines

There are 4 types of splines: Involute, Parallel key, helical, and ball. Learn about their characteristics. And, if you’re not sure what they are, you can always request a quotation. These splines are commonly used for building special machinery, repair jobs, and other applications. The CZPT Manufacturing Company manufactures these shafts. It is a specialty manufacturer and we welcome your business.

Involute splines

The involute spline provides a more rigid and durable structure, and is available in a variety of diameters and spline counts. Generally, steel, carbon steel, or titanium are used as raw materials. Other materials, such as carbon fiber, may be suitable. However, titanium can be difficult to produce, so some manufacturers make splines using other constituents.