Product Description

Our factory

Loading

FAQ:

Q1: How do you guarantee quality?

A: We take quality inspect records from raw material to finished product.

The former department bear 100% responsibility for next process to guarantee quality.

Q2: Can you produce if we have samples only?

A: Our technical ability is strong enough to deal with different types of spring.

Sample drawing and customers’ interests will be protected well.

Q3: Is it possible to have sample for quality testing?

A: Same or similar sample are available for free.

Q4: What is your MOQ?

A: For common material size, MOQ requires 30~50 pcs;

For special material size, Moq requires 3 ton or more;

Q5: What about the package of the product?

A:The goods will be packed according to your requirements and in well protection before delivery.

Q6: What is your terms of payment?

A: T/T, L/C at sight , Western Union.

Q7: What’s the delivery time ?

A: Most of parts are available in storage. For container delivery, 1 container can finish loading in 10 days.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 6 Month |

|---|---|

| Warranty: | 6 Month |

| Type: | Suspension |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

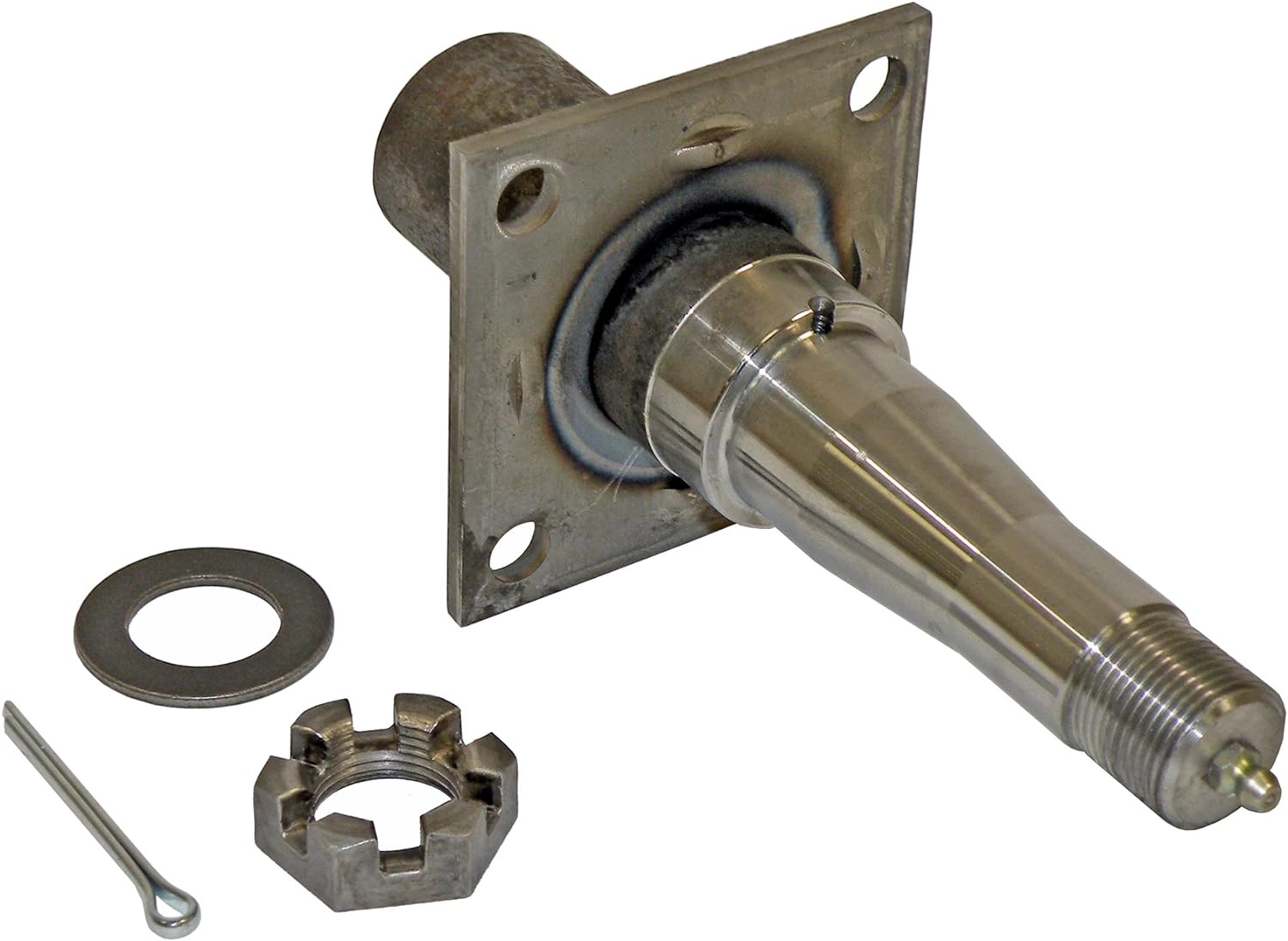

Can you explain the role of bearings in conjunction with trailer spindles in towing systems?

Trailer bearings play a critical role in conjunction with trailer spindles in towing systems. Here’s an explanation of their role:

Trailer bearings are components that facilitate the smooth rotation of the trailer wheels around the spindles. They are located within the hub assembly and provide a low-friction interface between the stationary spindle and the rotating wheel. The bearings allow the trailer wheels to rotate freely while supporting the weight of the trailer and its cargo.

The primary functions of bearings in conjunction with trailer spindles are:

- Load Support: Bearings bear the weight of the trailer and its cargo, transferring the load from the axle to the wheels. They distribute the load evenly across the spindle, preventing excessive stress on any specific area and ensuring optimal load capacity.

- Reducing Friction: Bearings minimize friction between the stationary spindle and the rotating wheel hub. By providing a smooth, low-friction interface, they allow the wheels to rotate freely with minimal resistance. This reduces energy consumption and promotes efficient towing.

- Alignment and Stability: Bearings help maintain proper alignment and stability of the trailer wheels. They ensure that the wheels rotate in a straight line and prevent wobbling or uneven tire wear. This is crucial for safe and controlled towing, as improper wheel alignment can lead to handling issues and compromised stability.

- Shock Absorption: Bearings also play a role in absorbing shocks and vibrations encountered during towing. They provide a cushioning effect, reducing the impact of bumps and irregularities on the trailer wheels. This helps improve overall ride comfort and protects the trailer and its contents from excessive jolts or vibrations.

- Lubrication: Properly lubricated bearings reduce friction and heat generation. They also help prevent premature wear and damage to the bearing surfaces. Lubrication ensures smooth operation and extends the lifespan of the bearings and the overall functionality of the towing system.

It’s important to note that trailer bearings require regular maintenance, including inspection, cleaning, and lubrication, to ensure their optimal performance and longevity. Neglecting bearing maintenance can lead to overheating, premature wear, and ultimately, bearing failure, which can result in costly repairs and unsafe towing conditions.

When selecting bearings for trailer spindles, it’s crucial to choose high-quality bearings that are appropriate for the load capacity and towing conditions. It’s recommended to follow the manufacturer’s guidelines regarding bearing specifications, lubrication intervals, and maintenance procedures to ensure proper functioning of the bearings in conjunction with the trailer spindles.

In summary, trailer bearings are essential components in towing systems that work in conjunction with trailer spindles. They support the load, reduce friction, maintain alignment and stability, absorb shocks, and require regular maintenance to ensure optimal functionality and safe towing operations.

How does the choice of materials impact the durability and reliability of trailer spindles?

The choice of materials for trailer spindles has a significant impact on their durability and reliability. Here’s a detailed explanation:

The materials used in the construction of trailer spindles play a crucial role in determining their strength, corrosion resistance, and overall performance. Different materials offer varying levels of durability and reliability in different operating conditions and environments.

- Steel:

Steel is a commonly used material for trailer spindles due to its excellent strength and durability. Steel spindles are known for their ability to withstand heavy loads and provide reliable performance. They are often preferred for applications that require high load capacities, such as commercial trailers or trailers used in demanding industries. Steel spindles can handle rough terrains, frequent use, and challenging towing conditions.

- Aluminum:

Aluminum spindles offer several advantages, including lightweight construction and corrosion resistance. They are commonly used in applications where weight reduction is important, such as recreational trailers or trailers that require improved fuel efficiency. Aluminum spindles provide good durability and reliability while reducing the overall weight of the trailer, which can result in improved towing performance.

- Ductile Iron:

Ductile iron spindles offer a combination of strength, durability, and cost-effectiveness. They are known for their ability to withstand heavy loads and provide reliable performance in various towing applications. Ductile iron spindles are often chosen for their high strength-to-weight ratio and resistance to wear and deformation.

- Composite Materials:

Composite materials, such as fiberglass-reinforced polymers, are gaining popularity in the manufacturing of trailer spindles. These materials offer advantages such as high strength-to-weight ratio, corrosion resistance, and reduced maintenance requirements. Composite spindles can provide excellent durability and reliability while being lighter in weight compared to traditional materials like steel or iron.

When selecting the material for trailer spindles, it’s important to consider the specific requirements of the towing application. Factors such as load capacity, operating conditions, and environmental factors should be taken into account. Additionally, it’s crucial to follow the manufacturer’s recommendations regarding material selection to ensure compatibility with other trailer components and adherence to safety standards.

In summary, the choice of materials significantly impacts the durability and reliability of trailer spindles. Steel spindles offer excellent strength and durability, while aluminum spindles provide lightweight construction and corrosion resistance. Ductile iron spindles offer a combination of strength and cost-effectiveness. Composite materials offer a lightweight alternative with high strength-to-weight ratios. By selecting the appropriate material based on the specific towing requirements, trailer owners can ensure the longevity, performance, and reliability of their trailer spindles.

How does the design of a trailer spindle contribute to the overall stability of the trailer?

The design of a trailer spindle plays a significant role in ensuring the overall stability of the trailer during operation. Here’s a detailed explanation of how the design of a trailer spindle contributes to trailer stability:

- Secure Wheel Attachment:

The design of the trailer spindle includes features that provide a secure attachment point for the trailer wheels. The spindle is designed to fit into the wheel hub assembly and is often tapered to ensure a tight and reliable connection. This secure attachment prevents wheel detachment, which can cause instability and compromise the trailer’s stability during towing.

- Load Distribution:

The design of the trailer spindle allows for proper load distribution across the axle. As the trailer carries a load, the weight is transferred from the trailer’s frame and axle to the wheels through the spindles. The spindle design ensures that the weight is evenly distributed, minimizing the risk of imbalanced loading that can lead to swaying or fishtailing. Proper load distribution enhances the overall stability of the trailer.

- Strength and Durability:

The design of the spindle takes into account the strength and durability requirements of the trailer. Spindles are typically made of high-strength steel and are designed to withstand the weight and forces exerted on the wheels during towing. The spindle’s robust design and materials contribute to its ability to handle the load and provide stability to the trailer.

- Wheel Alignment:

The design of the spindle also influences the alignment of the trailer wheels. Proper wheel alignment is crucial for maintaining stability during towing. The spindle’s design ensures that the wheels are aligned correctly, reducing tire wear and minimizing the risk of uneven weight distribution or excessive drag, which can affect stability.

- Smooth Wheel Rotation:

The design of the trailer spindle facilitates smooth wheel rotation. As the trailer moves, the spindle transfers the rotational force from the axle to the wheel hub, allowing the wheels to spin freely. Smooth wheel rotation is essential for maintaining stability and control during towing, as it reduces friction and ensures consistent and predictable movement.

- Compatibility with Suspension System:

The design of the spindle takes into consideration the trailer’s suspension system. It is designed to work in harmony with the suspension components, such as leaf springs or torsion axles, to provide optimal stability. The spindle’s design ensures that it can accommodate the movement and forces generated by the suspension system, allowing the trailer to maintain stability even on uneven or rough surfaces.

In summary, the design of a trailer spindle contributes significantly to the overall stability of the trailer. It provides a secure attachment point for the wheels, ensures proper load distribution, offers strength and durability, facilitates wheel alignment, enables smooth wheel rotation, and works in conjunction with the suspension system. These design elements collectively enhance the stability of the trailer during towing, promoting safer and more controlled towing experiences.

editor by CX 2024-02-25

China Custom Trailer Parts 12 Inch Brake Drum Trailer Axle Parts Hub Drum and Hydraulic Brake Hub Electric Drum Brakes near me supplier

Product Description

Product Description

- One piece unit includes hub drum,studs,bearing races(press in).

- Bearings,cap,seal,lug nuts,spindles,spindle washers,spindle nuts also available.

- Bolt hole,PCD and LOGO could be customised.

- Single-piece assembly makes installation a snap, whether you’re retrofitting or switching from drum brakes.

- Machined process minimizes runout and warping.

- Contaminants can’t get in between rotor and hub.

- Balanced unit provides smooth ride.

- Vented design effectively dissipates heat, preventing heat-related damage.

- 1/2″ ,7/16″wheel studs and industry-standard races are included.

- HT250/G3000 cast iron construction ensures a favorable friction coefficient for necessary stopping power.

Product Parameters

| Dia. | Model No. | PCD | Bearings Outer | Bearing Outside Cup Outer | Bearings Inner | Bearing Outside Cup Inner | Loading Capacity | Brake Size |

| 7″ | HD-54522 | 5×4.5″(5×114.3) | L44649 | L44610 | L44649 | L44610 | 2000lbs | 7″x1.25″ |

| 9″ | HD9X1.75 | 5×4.5″(5×114.3) | LM11949 | LM11910 | LM67048 | LM67571 | 3000lbs | 9″x1.75″ |

| 10″ | HD2-5425 | 5×4.25″(5×107.9) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 10″ | HD2-545 | 5×4.5″(5×114.3) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 10″ | HD3-545 | 5×4.5″(5×114.3) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 10″ | HD2-5475 | 5×4.75″(5×120.6) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 10″ | HD2-550 | 5×5″(5×127) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 10″ | HD2-555 | 5×5.5″(5×139.7) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 10″ | HD-65535 | 6×5.5″(6×139.7) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 12″ | HD-240 | 5X257.05 spoke UTG | LM67048 | LM67571 | L68149 | L68111 | 4000lbs | 12″x2″ |

| 12″ | HD-220 | 5×255.6 spoke UTG | LM67048 | LM67571 | L68149 | L68111 | 4000lbs | 12″x2″ |

| 12″ | HD-174 | 5X257 spoke UTG | 15123 | 15245 | 25580 | 25520 | 6000lbs | 12″x2″ |

| 12″ | HD2-655 | 6×5.5″(6×139.7) | 15123 | 15245 | 25580 | 25520 | 5200lbs | 12″x2″ |

| 12″ | HD9-136 | 6×5.5″(6×139.7) | 15123 | 15245 | 25580 | 25520 | 5200lbs | 12″x2″ |

| 12″ | HD2-865 | 8×6.5″(8×165.1) | 14125A | 14276 | 25580 | 25520 | 7000 lbs | 12″x2″ |

| 12″ | HD9-138 | 8×6.5″(8×165.1) | 14125A | 14276 | 25580 | 25520 | 7000 lbs | 12″x2″ |

| 12.25″ | HD-86580 | 8×6.5″(8×165.1) | 57175 | 57120 | 25580 | 25520 | 8000lbs | 12.25″x3.375″ |

| 12.25″ | HD-86510 | 8×6.5″(8×165.1) | 25580 | 25520 | 387A | 382A | 10000lbs | 12.25″x3.375″ |

| 12.25″ | HD-86512 | 8×6.5″(8×165.1) | 28682 | 28622 | 3984 | 3920 | 12000lbs | 12.25:x5″ |

| 12.25″ | HD-044 | 8×6.5″(8×165.1) | 25580 | 25520 | 387A | 382A | 12000lbs | 12.25″x4″ |

| 9″ | HT 5×4.25″ | 5×4.25″(5×107.95) | LM12749 | LM12710 | L68149 | L68110 | 3000lbs | 9″x1.75″ |

| 9″ | FORD 5×4.5″ | 5×4.5″(5×114.3) | LM12749 | LM12710 | L68149 | L68110 | 3000lbs | 9″x1.75″ |

| 9″ | HQ 5×4.75″ | 5×4.75″(5×120.65) | LM12749 | LM12710 | L68149 | L68110 | 3000lbs | 9″x1.75″ |

| 9″ | LANDCRUISER 6×5.5″ | 6×5.5″(6×139.7) | LM12749 | LM12710 | L68149 | L68110 | 3000lbs | 9″x1.75″ |

| 10″ | HT 5×4.25″ | 5×4.25″(5×107.95) | LM12749 | LM12710 | L68149 | L68110 | 3500lbs | 10″x2.25″ |

| 10″ | FORD 5×4.5″ | 5×4.5″(5 x114.3) | LM12749 | LM12710 | L68149 | L68110 | 3500lbs | 10″x2.25″ |

| 10″ | HQ 5×4.75″ | 5×4.75″(5×120.65) | LM12749 | LM12710 | L68149 | L68110 | 3500lbs | 10″x2.25″ |

| 10″ | LANDCRUISER 6×5.5″ | 6×5.5″(6×139.7) | LM12749 | LM12710 | L68149 | L68110 | 3500lbs | 10″x2.25″ |

Packaging & Shipping

Our Advantages

Company Profile

HangZhou Tsingleader Industry Co., Ltd. is located in the beautiful HangZhou city. We specialize in the production of trailer parts, axle and transmission of engineering machinery and special engineering and agricultural machinery.

Over the past years, Tsingleader Industry has invested 4 manufacturing plants in China. Following the principle of “quality assurance, abiding by the contract, reciprocity, mutual benefit and first-class services”, we have won the trust from our clients both at home and abroad.

Our annual sales amount reaches USD 5 million and our products have been exported to North and South America, Europe ,Africa,South Asia and the Middle East.

We sincerely hope to become your earnest business partner and your contact will be warmly welcomed.

Axle Spindle Types and Features

The axle spindle is an integral part of your vehicle’s suspension. There are several different types and features, including mounting methods, bearings, and functions. Read on for some basic information on axle spindles. The next part of the article will cover how to choose the correct axle spindle for your vehicle. This article will also discuss the different types of spindles available, including the differences between the rear and front bearings.

Features

The improved axle spindle nut assembly is capable of providing additional performance benefits, including increased tire life and reduced seal failure. Its keyway features and radially inwardly extending teeth allow nut adjustment to be accomplished with precision. The invention further provides a unique, multi-piece locking mechanism that minimizes leakage and torque transfer. Its principles and features are detailed in the appended claims. For example, the improved axle spindle nut assembly is designed for use in vehicles that are equipped with a steering system.

The axle spindle nut assembly includes a nut 252 with threads 256 on its inner periphery. The axle spindle 50 also features threads 198 on its outer periphery. The nut is threaded onto the outboard end of the axle spindle 50 until it contacts the inboard surface of the axle spacer 26. In the assembled state, a bearing spacer 58 is also present on the axle spindle.

The axle spindle nut assembly can reduce axial end play between the wheel end assembly 52 and the axle spindle 50. It can be tightened to an extreme torque level, but if the thread faces separate, it will undercompress the bearing cone and spacer group. To minimize these disadvantages, the axle spindle nut assembly is a critical component of a wheel-end assembly. There are several types of axle spindle nuts.

The third embodiment of the axle spindle nut assembly 300 comprises an inner washer 202, an outer washer 310, and at least 1 screw 320. The axle spindle nut assembly 300 secures and preloads bearing cones 55, 57. Unlike the first embodiment, the axle spindle nut assembly 300 uses the inner washer 202, which is optional in the third embodiment. The inner washer 202 and outer washer 310 are similar to those of the first embodiment.

Functions

An axle spindle is 1 of the most important components of a vehicle’s suspension system. The spindle retains the position of bearings and a spacer in an axle by providing clamp force. The inner nut of an axle spindle should be properly torqued to ensure a secure fit. A spindle nut is also responsible for compressing bearings and spacers. If any of these components are missing, the spindle will not work properly.

An axle spindle is used in rear wheel drive cars. It carries the weight of the vehicle on the axle casing and transfers the torque from the differential to the wheels. The axle spindle and hub are secured on the spindle by large nuts. The axle spindle is a vital component of rear wheel drive vehicles. Hence, it is essential to understand the functions of axle spindle. These components are responsible for the smooth operation of a vehicle’s suspension system.

Axle spindles can be mounted in 3 ways: in the typical axle assembly, the spindles are bolted onto the ends of the tubular axle, and the axle is suspended by springs. Short stub-axle mounting uses a torsion beam that flexes to provide a smooth ride. A second washer is used to prevent excessive rotation of the axle spindle.

Apart from being a crucial component of the suspension system, the spindles of the wheels are responsible for guiding the vehicle in a straight line. They are connected to the steering axis and are used in different types of suspension systems. European cars use a MacPherson Strut suspension system in which the spindle is connected to the arms in the front and rear of the suspension frame. The MacPherson strut allows the shock absorber housing to turn the wheel.

Methods of mounting

Various methods of mounting axle spindle are available. In general, these methods involve forming a tubular blank of uniform cross section and thickness, and receiving the bearing assembly against it. The spindle is then secured using a collar, which also serves as a bearing stop. In some cases, additional features are used to provide greater security. Some of these features may not be suitable for all applications. But they are generally suitable.

Axle spindle forming is usually done by progressive steps using hollow punches. The metallic body of the punch has an inner work surface, which receives the axle blank. A mandrel is fixed within the work opening of the punch. The punch body’s work surface forges the spindle about the mandrel. The punch has 2 ends, a closed and an open one.

A wheeled vehicle axle assembly (10) includes a cylindrical housing member (12 a) and a plurality of spindle mounting flanges (30) secured on the housing member. The spindles (16) are firmly attached to the housing member by means of coupling members. The coupling members are configured to distribute the bending loads imposed on the spindle by the axle. It is important to note that the coupling members can be either threaded or screwed.

Traditionally, axle spindles were made from tubular blanks of irregular thickness. This method allowed for a gradual reduction in diameter and eliminated the need for extra metal within the spindle. Similarly, axles made by cold forming eliminate the need for additional metal in the spindle. In this way, the overall cost of manufacture is also reduced. The material used for manufacturing axles also determines the size and shape of the final product.

Bearings

A nut 16 is used to retain the wheel bearings on axle spindle 12. The nut comprises several parts. The first portion includes a plurality of threads and a deformable second portion. The nut may be disposed on the inboard or outboard end of the axle spindle. This type of nut is typically secured to the axle spindle by a retaining nut.

The bearings are installed in the spindle to allow the wheel hub to rotate. While bearings are greased, they can dry out over time. Consequently, you may hear a loud clicking sound when turning your vehicle. Alternatively, you may notice grease on the edges of your tires. Bearing failure can cause severe damage to your axle spindle. If you notice any of these symptoms, you may need to replace the bearings on your axle spindle. Fortunately, you can purchase the necessary bearing parts at O’Reilly Auto Parts.

There are 3 ways to mount an axle spindle. A typical axle assembly has the spindles bolted to the ends of the tubular axle. A torsion beam is also used to mount the spindles on the axle. This torsion beam acts like a spring to help make the ride smooth and bump-free. Lastly, the axle spindle is sometimes mounted as a bolt-on component.

Cost

If your axle spindle has been damaged, you may need to have it replaced. This part of the axle is relatively easy to replace, but you need to know how to do it correctly. To replace your axle spindle, you must first remove the damaged one. To do this, a technician will cut the weld. They will then thread the new 1 into the axle tube and torque it to specification. After that, they will weld the new axle spindle into place.

When you are thinking about the cost of an axle spindle replacement, you must first determine if it is worth it for your vehicle. It is generally a good idea to replace the spindle only if it is causing damage to your vehicle. You can also replace your axle housing if it is deteriorating. If you do not replace the spindle, you can risk damaging the axle housing. To save money, you can consider using a repair kit.

You can also purchase an axle nut socket set. Most wrenches have an adjusting socket for this purpose. The socket set should be suitable for most vehicle types. Axle spindle replacement costs around $500 to $600 before tax. However, you should be aware that these costs vary widely based on the type of vehicle you have. The parts can cost between $430 and $480, and the labor can cost anywhere from $50 to 70.

China best Tri-Axles 60ton Low Bed Semi Truck Trailer China Heavy Duty 4 Axles 80 Tons Drop Deck Low Bed Semi Trailer with Hydraulic Ramps with Best Sales

Product Description

Tri-Axles 60ton Low Bed Semi Truck Trailer China Heavy Duty 4 Axles 80 Tons Drop Deck Low Bed Semi Trailer with Hydraulic Ramps

MAIN PERFORMANCE

| Product Specification | ||||

| 1 | Type | Semitrailer | ||

| 2 | Product Name | Low Bed Semitrailer | ||

| 3 | Dimension | 13000x3000x1600mm | ||

| 4 | Tare Weight | 9240kg | ||

| 5 | Payload | 44t | ||

| 6

|

Running System | Axles | FUWA , BPW, CZPT brand,13t/16t/20t Good quality axles | |

| Suspension | Tri-axle 10-pcs leaf spring suspension with equalizer beam (we can choose the Air suspension depend on customer requirement) |

|||

| Tires | Linglong, Double Coin, Triangle brand 11.00R20/8.25R20/12.00R22.5, 12unit | |||

| 7 | Ladder | Manually operated or Hydraulic type | ||

| 8 | Braking System | Dual lines pneumatic brake system, WABCO Emergency Relay Valve; KORMEE ABS braking system |

||

| 9 | Frame | Main Beam | Q345B steel,Height 500, upper 16mm, lower 18mm. Mid web 10mm |

|

| Cross Beam | Mild Alloy Q235 | |||

| 10 | King Pin | Size: 50# (2”) or 90#(3.5”); Type: welded or assembled | ||

| 11 | Landing Gear | FUWA, JOST Brand Single side operation or double side operation, Static capacity 28Ton |

||

| 12 | Electrical & Paint | Electrical | Rear light, rear reflector, turn indicative light, side reflector, fog lamp, number plate light | |

| Lights & Reflectors | 24V, 7 lines | |||

| Painting | zinc-rich primer and modified urethane topcoat as customers’ choices. | |||

| Accessories | TOOL BOX (BOX ONLY)—PROVIDED WITH THE TRAILER TWO SPARE WHEEL HOLDER(WINCH),BUT NO SPARE TYRES |

|||

I.The Application and the Technical Highlights:

—The low bed semitrailers are mainly suitable for the MID/Long distance transportation of mechanical equipment, large objects, highway construction equipment, large tanks, power plant equipment or machine, and all sorts of steel products.

—The low bed semitrailer can bed divide into flat bed low bed trailer, concave low bed trailer, tyres appear low bed trailer, tyres covered low bed trailer. The concave low bed trailer structured with tyre appeared style, the height of the cargo’s carrying platform from ground is 900mm.-Low platform makes the stable transportation.

—The chassis is ladder type,longitudinal beam section is H-shaped. It has good rigidity and high strength.

— High Quality Body and high-10sile steel for heavy loading capacity

— BPW, CZPT or Certificated Chinese Axles

—ABS brake system

—WABCO Vehicle Control System

—JOST ,FUWA or Chinese brand parking leg and king pin

—Air and Mechanical Suspension

—Strengthen the Chassis Instructure

II.The Advantage

***Frame:using the advanced assembly welded equipments to weld the space frame structure which formed by welded-type longitudinal beam (made of 16Mn steel plate) and the whole Run-through cross beam.Our consider the strength,stiffness and toughness of the frame and design the frame is strong enough to carry the heavy cargo.

***Suspension: Lightweight design.High-strength material with strong carrying capacity, remarkable wear resistance property and performance stability and long service life.Wheel Track adjustable easily and accurately, which protect the tires from abnormal wear.Passed strict bench testing and road testing.

***Axle:Specially processed one-piece spindle of high quality low alloy steel, which possesses strong loading capacity, long life, light weight and remarkable performance.High machining precision of the braking system makes the braking performance more stable.

III.Advanced Process

~~~Design Drawing: Before production, we will sent the design drawing to our customer to confirm the detail of the vehicle. We hope we can supply the most suitable product to our customer.

~~~Cutting and Welding: The I beam cutting adopt the Computer Numerical Control Plasma Cutting Machine. The I beam welding adopt the Gantry Main Sill Welding Machine.

~~~The Beam Welding: Main beam and side beam all use I-shaped beam, it can ensure the trailer more durable.Reinforced rear plate can avoid the rear plate was broken away when heavy duty machines climbing the ramp of trailer.

~~~Surface Treatment: In order to remove the rust of the trailer body, we use the sand blasting to retreat the surface of the trailer.

The trailer can have the beautiful appearance,the painting will be coating evenly, firm adhension, gloss more durable

~~~Painting: One layer of the anti-rust painting, 2 layer of painting

~~~Test: We will test the quality of the trailer before delivery.

IV.The Detail of the Low Bed Trailer

V. Classification Of The Low Bed Trailer

VI. Guarrantee For The Parts Of The Low Bed Traielr:

| ITEM NAME | WARRANTY | ITEM NAME | WARRANTY | |||

| MAIN FRAME | FRAME | 1 YEAR | RUNNING GEAR | AXLE | 6 MONTHS | |

| SUSPENSION | 6 MONTHS | AXLE BEARING | 3 MONTHS | |||

| KING PIN | 1 YEAR | WHEEL HUB | 3 MONTHS | |||

| BALANCE ARM | 3 MONTHS | |||||

| ITEM NAME | WARRANTY | ITEM NAME | WARRANTY | |||

| BRAKING DEVICE | BRAKE DRUM | 3 MONTHS | SUPPORT DEVICE | LXIHU (WEST LAKE) DIS. GEAR | 6 MONTHS | |

| BRKE CHAMBER | 3 MONTHS | SPARE WHEEL CARRIER | 6 MONTHS | |||

| AIR RESERVOIR | 6 MONTHS | |||||

| ITEM NAME | WARRANTY | |||||

| OTHERS | LEAF SPRING | 3 MONTHS | ||||

| BRAKE CHAMBER DIAPHRAGM | 3 MONTHS | |||||

| EMERGENCY RELAY VALVE | 3 MONTHS | |||||

| BRAKE SHOE | 3 MONTHS | |||||

| RELAY VALVE | 3 MONTHS | |||||

VII. DEALING PROCESS

1. You send us an inquiries on your desired trailer through our contact information.

2. We shall reply you in 12 hours after we received our inquiry.

3. We will negotiate the detail of the trailer on your requirement.

4. Confirmed on the tech data.

5. Sign contract.

6.30% down payment or LC issuing.

7. Production

8. The Manufacturig process with updated news.

9. The Production completement.

10.Balance payment .

11.Arrange Shipment and Custom Clearance

12. A/S service for 1 year.

Tri-Axles Low Bed Semi Trailer

Calculating the Deflection of a Worm Shaft

In this article, we’ll discuss how to calculate the deflection of a worm gear’s worm shaft. We’ll also discuss the characteristics of a worm gear, including its tooth forces. And we’ll cover the important characteristics of a worm gear. Read on to learn more! Here are some things to consider before purchasing a worm gear. We hope you enjoy learning! After reading this article, you’ll be well-equipped to choose a worm gear to match your needs.

Calculation of worm shaft deflection

The main goal of the calculations is to determine the deflection of a worm. Worms are used to turn gears and mechanical devices. This type of transmission uses a worm. The worm diameter and the number of teeth are inputted into the calculation gradually. Then, a table with proper solutions is shown on the screen. After completing the table, you can then move on to the main calculation. You can change the strength parameters as well.

The maximum worm shaft deflection is calculated using the finite element method (FEM). The model has many parameters, including the size of the elements and boundary conditions. The results from these simulations are compared to the corresponding analytical values to calculate the maximum deflection. The result is a table that displays the maximum worm shaft deflection. The tables can be downloaded below. You can also find more information about the different deflection formulas and their applications.

The calculation method used by DIN EN 10084 is based on the hardened cemented worm of 16MnCr5. Then, you can use DIN EN 10084 (CuSn12Ni2-C-GZ) and DIN EN 1982 (CuAl10Fe5Ne5-C-GZ). Then, you can enter the worm face width, either manually or using the auto-suggest option.

Common methods for the calculation of worm shaft deflection provide a good approximation of deflection but do not account for geometric modifications on the worm. While Norgauer’s 2021 approach addresses these issues, it fails to account for the helical winding of the worm teeth and overestimates the stiffening effect of gearing. More sophisticated approaches are required for the efficient design of thin worm shafts.

Worm gears have a low noise and vibration compared to other types of mechanical devices. However, worm gears are often limited by the amount of wear that occurs on the softer worm wheel. Worm shaft deflection is a significant influencing factor for noise and wear. The calculation method for worm gear deflection is available in ISO/TR 14521, DIN 3996, and AGMA 6022.

The worm gear can be designed with a precise transmission ratio. The calculation involves dividing the transmission ratio between more stages in a gearbox. Power transmission input parameters affect the gearing properties, as well as the material of the worm/gear. To achieve a better efficiency, the worm/gear material should match the conditions that are to be experienced. The worm gear can be a self-locking transmission.

The worm gearbox contains several machine elements. The main contributors to the total power loss are the axial loads and bearing losses on the worm shaft. Hence, different bearing configurations are studied. One type includes locating/non-locating bearing arrangements. The other is tapered roller bearings. The worm gear drives are considered when locating versus non-locating bearings. The analysis of worm gear drives is also an investigation of the X-arrangement and four-point contact bearings.

Influence of tooth forces on bending stiffness of a worm gear

The bending stiffness of a worm gear is dependent on tooth forces. Tooth forces increase as the power density increases, but this also leads to increased worm shaft deflection. The resulting deflection can affect efficiency, wear load capacity, and NVH behavior. Continuous improvements in bronze materials, lubricants, and manufacturing quality have enabled worm gear manufacturers to produce increasingly high power densities.

Standardized calculation methods take into account the supporting effect of the toothing on the worm shaft. However, overhung worm gears are not included in the calculation. In addition, the toothing area is not taken into account unless the shaft is designed next to the worm gear. Similarly, the root diameter is treated as the equivalent bending diameter, but this ignores the supporting effect of the worm toothing.

A generalized formula is provided to estimate the STE contribution to vibratory excitation. The results are applicable to any gear with a meshing pattern. It is recommended that engineers test different meshing methods to obtain more accurate results. One way to test tooth-meshing surfaces is to use a finite element stress and mesh subprogram. This software will measure tooth-bending stresses under dynamic loads.

The effect of tooth-brushing and lubricant on bending stiffness can be achieved by increasing the pressure angle of the worm pair. This can reduce tooth bending stresses in the worm gear. A further method is to add a load-loaded tooth-contact analysis (CCTA). This is also used to analyze mismatched ZC1 worm drive. The results obtained with the technique have been widely applied to various types of gearing.

In this study, we found that the ring gear’s bending stiffness is highly influenced by the teeth. The chamfered root of the ring gear is larger than the slot width. Thus, the ring gear’s bending stiffness varies with its tooth width, which increases with the ring wall thickness. Furthermore, a variation in the ring wall thickness of the worm gear causes a greater deviation from the design specification.

To understand the impact of the teeth on the bending stiffness of a worm gear, it is important to know the root shape. Involute teeth are susceptible to bending stress and can break under extreme conditions. A tooth-breakage analysis can control this by determining the root shape and the bending stiffness. The optimization of the root shape directly on the final gear minimizes the bending stress in the involute teeth.

The influence of tooth forces on the bending stiffness of a worm gear was investigated using the CZPT Spiral Bevel Gear Test Facility. In this study, multiple teeth of a spiral bevel pinion were instrumented with strain gages and tested at speeds ranging from static to 14400 RPM. The tests were performed with power levels as high as 540 kW. The results obtained were compared with the analysis of a three-dimensional finite element model.

Characteristics of worm gears

Worm gears are unique types of gears. They feature a variety of characteristics and applications. This article will examine the characteristics and benefits of worm gears. Then, we’ll examine the common applications of worm gears. Let’s take a look! Before we dive in to worm gears, let’s review their capabilities. Hopefully, you’ll see how versatile these gears are.

A worm gear can achieve massive reduction ratios with little effort. By adding circumference to the wheel, the worm can greatly increase its torque and decrease its speed. Conventional gearsets require multiple reductions to achieve the same reduction ratio. Worm gears have fewer moving parts, so there are fewer places for failure. However, they can’t reverse the direction of power. This is because the friction between the worm and wheel makes it impossible to move the worm backwards.

Worm gears are widely used in elevators, hoists, and lifts. They are particularly useful in applications where stopping speed is critical. They can be incorporated with smaller brakes to ensure safety, but shouldn’t be relied upon as a primary braking system. Generally, they are self-locking, so they are a good choice for many applications. They also have many benefits, including increased efficiency and safety.

Worm gears are designed to achieve a specific reduction ratio. They are typically arranged between the input and output shafts of a motor and a load. The 2 shafts are often positioned at an angle that ensures proper alignment. Worm gear gears have a center spacing of a frame size. The center spacing of the gear and worm shaft determines the axial pitch. For instance, if the gearsets are set at a radial distance, a smaller outer diameter is necessary.

Worm gears’ sliding contact reduces efficiency. But it also ensures quiet operation. The sliding action limits the efficiency of worm gears to 30% to 50%. A few techniques are introduced herein to minimize friction and to produce good entrance and exit gaps. You’ll soon see why they’re such a versatile choice for your needs! So, if you’re considering purchasing a worm gear, make sure you read this article to learn more about its characteristics!

An embodiment of a worm gear is described in FIGS. 19 and 20. An alternate embodiment of the system uses a single motor and a single worm 153. The worm 153 turns a gear which drives an arm 152. The arm 152, in turn, moves the lens/mirr assembly 10 by varying the elevation angle. The motor control unit 114 then tracks the elevation angle of the lens/mirr assembly 10 in relation to the reference position.

The worm wheel and worm are both made of metal. However, the brass worm and wheel are made of brass, which is a yellow metal. Their lubricant selections are more flexible, but they’re limited by additive restrictions due to their yellow metal. Plastic on metal worm gears are generally found in light load applications. The lubricant used depends on the type of plastic, as many types of plastics react to hydrocarbons found in regular lubricant. For this reason, you need a non-reactive lubricant.

China manufacturer Compare CZPT Diesel Wood Chipper DH-40, Trailer Mounted Hydraulic Feeing Rolls near me shop

Product Description

Specifications

Durable Chromium CR-12 blades.;

Maintenance simple,; low noise.;

High efficiency 10-12m3/H.;

CE approved(CE No.; –110727/WFA516);

Specifications:;

1.; Durable Chromium CR-12 blades.;

2.; Maintenance simple,; low noise.;

3.; High efficiency 10-12m3/H.;

4.; CE approved(CE No.; –110727/WFA516);

40HP Diesel Engine Auto Hydraulic Feed Wood Cutting Machinery

—–DH-40 Wood Chipper with CE Certificate.;

Features:;

1.; CZPT or Changchai 40HP/30HP/22HP/18HP diesel engine.;

2.;8 inch(1-25cm); Max.; Chip capacity,; chip size 10-50mm adjustable.;

3.; High quality CR-12 material cutting blades

4.;3 blades,; round disc housing,; easy to change blades and belts.;

5.; Double hydraulic feeding rolls,; round flywheel house,; hydraulic tank,; gear pump,;

Protect safety guard optional.;

6.; Free flow valve added on the new model wood chipper.;

7.; Discharge hood can rotate in 360 degrees

8.; Optional color according to specific requirement.;

9.;2″ hitching ball,; can use in Europe,; Australia,; USA etc.;

10.; Jockey wheel,; road/turf tyre

Usage:;

1.; The small chips made by the wood chipper can be used for animal bedding,; for the forestry and

Soil protecting,; for new energy making,; for compost and for charcoal.;

2.; Some customers use their colored garden waste chips,; cover the soil and made the garden

Beautiful; Some of them use the garden waste chips in the fireplace.;

Packaging & Delivery

Packaging Detail:; 1.; One 20GP container can hold 10units in iron crate pcaking.; 2.; One 40HC container can hold 20units in iron crate packing.;

Delivery Detail:; 10-15days after sign the contract.;

| Model | DH-18/DH-22 | DH-3030/DH-40 | |

| Power | 18hp/22hp | 30/40hp | |

| Engine | one cylinders Electric started diesel engine | 3cylinders Electric started diesel engine | |

| Chipper capacity | 8″ diameter/200mm | 8″ diameter/200mm | |

| Feeding system | Mechanical / hydraulic | Hydraulic | |

| Rotor plate size | 640mm | 760mm | |

| Rotor plate weight | 85kg | 82kg | |

| Knives number | 1stationaryknife: 2rotor knives | 1stationaryknife: 2rotor knives | |

| Dimensions(Hopper discharge) | 1300x1400x1100mm | 1900x1300x2500mm | |

| Feed Hopper inner Opening | 200x220mm | 500mmx500mm | |

| Discharge Hood Height | 1800mm | 2000mm | |

| Rated RPM | 1080 | 1280 | |

| Discharge hood rotates | 360 degree | 360 degree | |

| Settings | turning lights, easy discharge hood, 2″ Ball Hitch, Safety Chains and leaf spring on axle | ||

| Gross Weight | 690kg/730kg | 810kg | |

| Working efficiency | 10-12CBM/H | 12-15CBM/H | |

Why Checking the Drive Shaft is Important

If you hear clicking noises while driving, your driveshaft may need repair. An experienced mechanic can tell if the noise is coming from 1 side or both sides. This problem is usually related to the torque converter. Read on to learn why it’s so important to have your driveshaft inspected by an auto mechanic. Here are some symptoms to look for. Clicking noises can be caused by many different things. You should first check if the noise is coming from the front or the rear of the vehicle.

hollow drive shaft

Hollow driveshafts have many benefits. They are light and reduce the overall weight of the vehicle. The largest manufacturer of these components in the world is CZPT. They also offer lightweight solutions for various applications, such as high-performance axles. CZPT driveshafts are manufactured using state-of-the-art technology. They offer excellent quality at competitive prices.

The inner diameter of the hollow shaft reduces the magnitude of the internal forces, thereby reducing the amount of torque transmitted. Unlike solid shafts, hollow shafts are getting stronger. The material inside the hollow shaft is slightly lighter, which further reduces its weight and overall torque. However, this also increases its drag at high speeds. This means that in many applications hollow driveshafts are not as efficient as solid driveshafts.

A conventional hollow drive shaft consists of a first rod 14 and a second rod 14 on both sides. The first rod is connected with the second rod, and the second rod extends in the rotation direction. The 2 rods are then friction welded to the central area of the hollow shaft. The frictional heat generated during the relative rotation helps to connect the 2 parts. Hollow drive shafts can be used in internal combustion engines and environmentally-friendly vehicles.

The main advantage of a hollow driveshaft is weight reduction. The splines of the hollow drive shaft can be designed to be smaller than the outside diameter of the hollow shaft, which can significantly reduce weight. Hollow shafts are also less likely to jam compared to solid shafts. Hollow driveshafts are expected to eventually occupy the world market for automotive driveshafts. Its advantages include fuel efficiency and greater flexibility compared to solid prop shafts.

Cardan shaft

Cardan shafts are a popular choice in industrial machinery. They are used to transmit power from 1 machine to another and are available in a variety of sizes and shapes. They are available in a variety of materials, including steel, copper, and aluminum. If you plan to install 1 of these shafts, it is important to know the different types of Cardan shafts available. To find the best option, browse the catalog.

Telescopic or “Cardan” prop shafts, also known as U-joints, are ideal for efficient torque transfer between the drive and output system. They are efficient, lightweight, and energy-efficient. They employ advanced methods, including finite element modeling (FEM), to ensure maximum performance, weight, and efficiency. Additionally, the Cardan shaft has an adjustable length for easy repositioning.

Another popular choice for driveshafts is the Cardan shaft, also known as a driveshaft. The purpose of the driveshaft is to transfer torque from the engine to the wheels. They are typically used in high-performance car engines. Some types are made of brass, iron, or steel and have unique surface designs. Cardan shafts are available in inclined and parallel configurations.

Single Cardan shafts are a common replacement for standard Cardan shafts, but if you are looking for dual Cardan shafts for your vehicle, you will want to choose the 1310 series. This type is great for lifted jeeps and requires a CV-compatible transfer case. Some even require axle spacers. The dual Cardan shafts are also designed for lifts, which means it’s a good choice for raising and lowering jeeps.

universal joint

Cardan joints are a good choice for drive shafts when operating at a constant speed. Their design allows a constant angular velocity ratio between the input and output shafts. Depending on the application, the recommended speed limit may vary depending on the operating angle, transmission power, and application. These recommendations must be based on pressure. The maximum permissible speed of the drive shaft is determined by determining the angular acceleration.

Because gimbal joints don’t require grease, they can last a long time but eventually fail. If they are poorly lubricated or dry, they can cause metal-to-metal contact. The same is true for U-joints that do not have oil filling capability. While they have a long lifespan, it can be difficult to spot warning signs that could indicate impending joint failure. To avoid this, check the drive shaft regularly.

U-joints should not exceed 70 percent of their lateral critical velocity. However, if this speed is exceeded, the part will experience unacceptable vibration, reducing its useful life. To determine the best U-joint for your application, please contact your universal joint supplier. Typically, lower speeds do not require balancing. In these cases, you should consider using a larger pitch diameter to reduce axial force.

To minimize the angular velocity and torque of the output shaft, the 2 joints must be in phase. Therefore, the output shaft angular displacement does not completely follow the input shaft. Instead, it will lead or lag. Figure 3 illustrates the angular velocity variation and peak displacement lead of the gimbal. The ratios are shown below. The correct torque for this application is 1360 in-Ibs.

Refurbished drive shaft

Refurbished driveshafts are a good choice for a number of reasons. They are cheaper than brand new alternatives and generally just as reliable. Driveshafts are essential to the function of any car, truck, or bus. These parts are made of hollow metal tubes. While this helps reduce weight and expense, it is vulnerable to external influences. If this happens, it may crack or bend. If the shaft suffers this type of damage, it can cause serious damage to the transmission.

A car’s driveshaft is a critical component that transmits torque from the engine to the wheels. A1 Drive Shaft is a global supplier of automotive driveshafts and related components. Their factory has the capability to refurbish and repair almost any make or model of driveshafts. Refurbished driveshafts are available for every make and model of vehicle. They can be found on the market for a variety of vehicles, including passenger cars, trucks, vans, and SUVs.

Unusual noises indicate that your driveshaft needs to be replaced. Worn U-joints and bushings can cause excessive vibration. These components cause wear on other parts of the drivetrain. If you notice any of these symptoms, please take your vehicle to the AAMCO Bay Area Center for a thorough inspection. If you suspect damage to the driveshaft, don’t wait another minute – it can be very dangerous.

The cost of replacing the drive shaft

The cost of replacing a driveshaft varies, but on average, this repair costs between $200 and $1,500. While this price may vary by vehicle, the cost of parts and labor is generally equal. If you do the repair yourself, you should know how much the parts and labor will cost before you start work. Some parts can be more expensive than others, so it’s a good idea to compare the cost of several locations before deciding where to go.

If you notice any of these symptoms, you should seek a repair shop immediately. If you are still not sure if the driveshaft is damaged, do not drive the car any distance until it is repaired. Symptoms to look for include lack of power, difficulty moving the car, squeaking, clanking, or vibrating when the vehicle is moving.

Parts used in drive shafts include center support bearings, slip joints, and U-joints. The price of the driveshaft varies by vehicle and may vary by model of the same year. Also, different types of driveshafts require different repair methods and are much more expensive. Overall, though, a driveshaft replacement costs between $300 and $1,300. The process may take about an hour, depending on the vehicle model.

Several factors can lead to the need to replace the drive shaft, including bearing corrosion, damaged seals, or other components. In some cases, the U-joint indicates that the drive shaft needs to be replaced. Even if the bearings and u-joints are in good condition, they will eventually break and require the replacement of the drive shaft. However, these parts are not cheap, and if a damaged driveshaft is a symptom of a bigger problem, you should take the time to replace the shaft.

China supplier Trailer Parts 12.25 Inch Brake Drum Trailer Axle Parts Hub Drum and Hydraulic Brake Hub Electric Drum Brakes with Good quality

Product Description

Product Description

- One piece unit includes hub drum,studs,bearing races(press in).

- Bearings,cap,seal,lug nuts,spindles,spindle washers,spindle nuts also available.

- Bolt hole,PCD and LOGO could be customised.

- Single-piece assembly makes installation a snap, whether you’re retrofitting or switching from drum brakes.

- Machined process minimizes runout and warping.

- Contaminants can’t get in between rotor and hub.

- Balanced unit provides smooth ride.

- Vented design effectively dissipates heat, preventing heat-related damage.

- 1/2″ ,7/16″wheel studs and industry-standard races are included.

- HT250/G3000 cast iron construction ensures a favorable friction coefficient for necessary stopping power.

Product Parameters

| Dia. | Model No. | PCD | Bearings Outer | Bearing Outside Cup Outer | Bearings Inner | Bearing Outside Cup Inner | Loading Capacity | Brake Size |

| 7″ | HD-54522 | 5×4.5″(5×114.3) | L44649 | L44610 | L44649 | L44610 | 2000lbs | 7″x1.25″ |

| 9″ | HD9X1.75 | 5×4.5″(5×114.3) | LM11949 | LM11910 | LM67048 | LM67571 | 3000lbs | 9″x1.75″ |

| 10″ | HD2-5425 | 5×4.25″(5×107.9) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 10″ | HD2-545 | 5×4.5″(5×114.3) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 10″ | HD3-545 | 5×4.5″(5×114.3) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 10″ | HD2-5475 | 5×4.75″(5×120.6) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 10″ | HD2-550 | 5×5″(5×127) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 10″ | HD2-555 | 5×5.5″(5×139.7) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 10″ | HD-65535 | 6×5.5″(6×139.7) | L44649 | L44610 | L68149 | L68111 | 3500lbs | 10″x2.25″ |

| 12″ | HD-240 | 5X257.05 spoke UTG | LM67048 | LM67571 | L68149 | L68111 | 4000lbs | 12″x2″ |

| 12″ | HD-220 | 5×255.6 spoke UTG | LM67048 | LM67571 | L68149 | L68111 | 4000lbs | 12″x2″ |

| 12″ | HD-174 | 5X257 spoke UTG | 15123 | 15245 | 25580 | 25520 | 6000lbs | 12″x2″ |

| 12″ | HD2-655 | 6×5.5″(6×139.7) | 15123 | 15245 | 25580 | 25520 | 5200lbs | 12″x2″ |

| 12″ | HD9-136 | 6×5.5″(6×139.7) | 15123 | 15245 | 25580 | 25520 | 5200lbs | 12″x2″ |

| 12″ | HD2-865 | 8×6.5″(8×165.1) | 14125A | 14276 | 25580 | 25520 | 7000 lbs | 12″x2″ |

| 12″ | HD9-138 | 8×6.5″(8×165.1) | 14125A | 14276 | 25580 | 25520 | 7000 lbs | 12″x2″ |

| 12.25″ | HD-86580 | 8×6.5″(8×165.1) | 57175 | 57120 | 25580 | 25520 | 8000lbs | 12.25″x3.375″ |

| 12.25″ | HD-86510 | 8×6.5″(8×165.1) | 25580 | 25520 | 387A | 382A | 10000lbs | 12.25″x3.375″ |

| 12.25″ | HD-86512 | 8×6.5″(8×165.1) | 28682 | 28622 | 3984 | 3920 | 12000lbs | 12.25:x5″ |

| 12.25″ | HD-044 | 8×6.5″(8×165.1) | 25580 | 25520 | 387A | 382A | 12000lbs | 12.25″x4″ |

| 9″ | HT 5×4.25″ | 5×4.25″(5×107.95) | LM12749 | LM12710 | L68149 | L68110 | 3000lbs | 9″x1.75″ |

| 9″ | FORD 5×4.5″ | 5×4.5″(5×114.3) | LM12749 | LM12710 | L68149 | L68110 | 3000lbs | 9″x1.75″ |

| 9″ | HQ 5×4.75″ | 5×4.75″(5×120.65) | LM12749 | LM12710 | L68149 | L68110 | 3000lbs | 9″x1.75″ |

| 9″ | LANDCRUISER 6×5.5″ | 6×5.5″(6×139.7) | LM12749 | LM12710 | L68149 | L68110 | 3000lbs | 9″x1.75″ |

| 10″ | HT 5×4.25″ | 5×4.25″(5×107.95) | LM12749 | LM12710 | L68149 | L68110 | 3500lbs | 10″x2.25″ |

| 10″ | FORD 5×4.5″ | 5×4.5″(5 x114.3) | LM12749 | LM12710 | L68149 | L68110 | 3500lbs | 10″x2.25″ |

| 10″ | HQ 5×4.75″ | 5×4.75″(5×120.65) | LM12749 | LM12710 | L68149 | L68110 | 3500lbs | 10″x2.25″ |

| 10″ | LANDCRUISER 6×5.5″ | 6×5.5″(6×139.7) | LM12749 | LM12710 | L68149 | L68110 | 3500lbs | 10″x2.25″ |

Packaging & Shipping

Our Advantages

Company Profile

HangZhou Tsingleader Industry Co., Ltd. is located in the beautiful HangZhou city. We specialize in the production of trailer parts, axle and transmission of engineering machinery and special engineering and agricultural machinery.

Over the past years, Tsingleader Industry has invested 4 manufacturing plants in China. Following the principle of “quality assurance, abiding by the contract, reciprocity, mutual benefit and first-class services”, we have won the trust from our clients both at home and abroad.

Our annual sales amount reaches USD 5 million and our products have been exported to North and South America, Europe ,Africa,South Asia and the Middle East.

We sincerely hope to become your earnest business partner and your contact will be warmly welcomed.

What Are the Advantages of a Splined Shaft?

If you are looking for the right splined shaft for your machine, you should know a few important things. First, what type of material should be used? Stainless steel is usually the most appropriate choice, because of its ability to offer low noise and fatigue failure. Secondly, it can be machined using a slotting or shaping machine. Lastly, it will ensure smooth motion. So, what are the advantages of a splined shaft?

Stainless steel is the best material for splined shafts

When choosing a splined shaft, you should consider its hardness, quality, and finish. Stainless steel has superior corrosion and wear resistance. Carbon steel is another good material for splined shafts. Carbon steel has a shallow carbon content (about 1.7%), which makes it more malleable and helps ensure smooth motion. But if you’re not willing to spend the money on stainless steel, consider other options.

There are 2 main types of splines: parallel splines and crowned splines. Involute splines have parallel grooves and allow linear and rotary motion. Helical splines have involute teeth and are oriented at an angle. This type allows for many teeth on the shaft and minimizes the stress concentration in the stationary joint.

Large evenly spaced splines are widely used in hydraulic systems, drivetrains, and machine tools. They are typically made from carbon steel (CR10) and stainless steel (AISI 304). This material is durable and meets the requirements of ISO 14-B, formerly DIN 5463-B. Splined shafts are typically made of stainless steel or C45 steel, though there are many other materials available.

Stainless steel is the best material for a splined shaft. This metal is also incredibly affordable. In most cases, stainless steel is the best choice for these shafts because it offers the best corrosion resistance. There are many different types of splined shafts, and each 1 is suited for a particular application. There are also many different types of stainless steel, so choose stainless steel if you want the best quality.

For those looking for high-quality splined shafts, CZPT Spline Shafts offer many benefits. They can reduce costs, improve positional accuracy, and reduce friction. With the CZPT TFE coating, splined shafts can reduce energy and heat buildup, and extend the life of your products. And, they’re easy to install – all you need to do is install them.

They provide low noise, low wear and fatigue failure

The splines in a splined shaft are composed of 2 main parts: the spline root fillet and the spline relief. The spline root fillet is the most critical part, because fatigue failure starts there and propagates to the relief. The spline relief is more susceptible to fatigue failure because of its involute tooth shape, which offers a lower stress to the shaft and has a smaller area of contact.

The fatigue life of splined shafts is determined by measuring the S-N curve. This is also known as the Wohler curve, and it is the relationship between stress amplitude and number of cycles. It depends on the material, geometry and way of loading. It can be obtained from a physical test on a uniform material specimen under a constant amplitude load. Approximations for low-alloy steel parts can be made using a lower-alloy steel material.

Splined shafts provide low noise, minimal wear and fatigue failure. However, some mechanical transmission elements need to be removed from the shaft during assembly and manufacturing processes. The shafts must still be capable of relative axial movement for functional purposes. As such, good spline joints are essential to high-quality torque transmission, minimal backlash, and low noise. The major failure modes of spline shafts include fretting corrosion, tooth breakage, and fatigue failure.

The outer disc carrier spline is susceptible to tensile stress and fatigue failure. High customer demands for low noise and low wear and fatigue failure makes splined shafts an excellent choice. A fractured spline gear coupling was received for analysis. It was installed near the top of a filter shaft and inserted into the gearbox motor. The service history was unknown. The fractured spline gear coupling had longitudinally cracked and arrested at the termination of the spline gear teeth. The spline gear teeth also exhibited wear and deformation.

A new spline coupling method detects fault propagation in hollow cylindrical splined shafts. A spline coupling is fabricated using an AE method with the spline section unrolled into a metal plate of the same thickness as the cylinder wall. In addition, the spline coupling is misaligned, which puts significant concentration on the spline teeth. This further accelerates the rate of fretting fatigue and wear.

A spline joint should be lubricated after 25 hours of operation. Frequent lubrication can increase maintenance costs and cause downtime. Moreover, the lubricant may retain abrasive particles at the interfaces. In some cases, lubricants can even cause misalignment, leading to premature failure. So, the lubrication of a spline coupling is vital in ensuring proper functioning of the shaft.

The design of a spline coupling can be optimized to enhance its wear resistance and reliability. Surface treatments, loads, and rotation affect the friction properties of a spline coupling. In addition, a finite element method was developed to predict wear of a floating spline coupling. This method is feasible and provides a reliable basis for predicting the wear and fatigue life of a spline coupling.

They can be machined using a slotting or shaping machine

Machines can be used to shape splined shafts in a variety of industries. They are useful in many applications, including gearboxes, braking systems, and axles. A slotted shaft can be manipulated in several ways, including hobbling, broaching, and slotting. In addition to shaping, splines are also useful in reducing bar diameter.

When using a slotting or shaping machine, the workpiece is held against a pedestal that has a uniform thickness. The machine is equipped with a stand column and limiting column (Figure 1), each positioned perpendicular to the upper surface of the pedestal. The limiting column axis is located on the same line as the stand column. During the slotting or shaping process, the tool is fed in and out until the desired space is achieved.

One process involves cutting splines into a shaft. Straddle milling, spline shaping, and spline cutting are 2 common processes used to create splined shafts. Straddle milling involves a fixed indexing fixture that holds the shaft steady, while rotating milling cutters cut the groove in the length of the shaft. Several passes are required to ensure uniformity throughout the spline.

Splines are a type of gear. The ridges or teeth on the drive shaft mesh with grooves in the mating piece. A splined shaft allows the transmission of torque to a mate piece while maximizing the power transfer. Splines are used in heavy vehicles, construction, agriculture, and massive earthmoving machinery. Splines are used in virtually every type of rotary motion, from axles to transmission systems. They also offer better fatigue life and reliability.

Slotting or shaping machines can also be used to shape splined shafts. Slotting machines are often used to machine splined shafts, because it is easier to make them with these machines. Using a slotting or shaping machine can result in splined shafts of different sizes. It is important to follow a set of spline standards to ensure your parts are manufactured to the highest standards.

A milling machine is another option for producing splined shafts. A spline shaft can be set up between 2 centers in an indexing fixture. Two side milling cutters are mounted on an arbor and a spacer and shims are inserted between them. The arbor and cutters are then mounted to a milling machine spindle. To make sure the cutters center themselves over the splined shaft, an adjustment must be made to the spindle of the machine.

The machining process is very different for internal and external splines. External splines can be broached, shaped, milled, or hobbed, while internal splines cannot. These machines use hard alloy, but they are not as good for internal splines. A machine with a slotting mechanism is necessary for these operations.

China OEM 200m Depth Trailer Mounted Rotary Hydraulic Irrigation Water Well Drilling Rig Machine with Good quality

Product Description

Products Description

Characteristics of XYC-200A tricycle-mounted hydraulic core drilling rig

XYC-200A tricycle-mounted hydraulic core drilling rig is multi-function hydraulic vehicle-mounted core drilling machine .

The tricycle is Tricar. The drilling rig, engine, BW-160 pump and hydraulic drill tower are all installed on the tricycle, so it

us easy for transportation.

XYC-200A tricycle-mounted hydraulic core drilling rig with BW160 pump which has high pressure and high flux, to ensure the

drilling depth and hole diameter.

The tricycle drilling rig is equipped with shift unit,so the drilling rig can move back and forth

The highest speed can reach 1045r/min with 5 gears, which improves the drilling efficiency

The drilling rig is Adopted 53*59 drilling rod, which has high rigidity and strong delivery torque

Equipped with taper clutch, made the machine easy to operate and free of maintenance.

Use large module planetary gear and add supporting frame, highly increased hoisting and braking ability of the winch.

Vertical spindle are fixed by 4 groups of bearings to ensure that the core rig is rigid enough for gravel layer and other

complex geological conditions.

| Drilling depth | 200m |

| Max. open hole diameter | 75-260mm |

| End hole diameter(mm) | 75 |

| Drill rod diameter | 50mm |

| Drilling tower height | 6500mm |

| Drilling angle | 90-75 |

| Spindle | |

| Spindle speed | 64/128/287/557r/min |

| Spindle stroke | 450mm |

| Hoist | |

| Max. single line hoisting capacity | 1600kg |

| Single line lifting speed | 17/35/75/151r/min |

| Tightrope diameter | 12.5mm |

| Tightrope cubic measure | 35mm |

| Hug floodgate belt width | 70mm |

| Mud Pump | |

| Type | Horizontal Single Urn Twin-action |

| Discharge displacement | 170l/min. |

| Diesel | S1115 22HP |

| Electric motor | 15kw,1440r/min |

| Max. pressure | 1.5mpa |

| Work pressure | 0.7mpa |

| Water inlet diameter | 30mm |

| Water outlet diameter | 25mm |

| Triangle conveyre belt | B1728mm |

| Chassis | |

| Chassis | Tricar(Pictures of vehicle-mounted drilling rigs for reference only) |

Product Overviews

Company Profile

Certificate

FAQ

How to Select a Worm Shaft and Gear For Your Project

You will learn about axial pitch PX and tooth parameters for a Worm Shaft 20 and Gear 22. Detailed information on these 2 components will help you select a suitable Worm Shaft. Read on to learn more….and get your hands on the most advanced gearbox ever created! Here are some tips for selecting a Worm Shaft and Gear for your project!…and a few things to keep in mind.

Gear 22

The tooth profile of Gear 22 on Worm Shaft 20 differs from that of a conventional gear. This is because the teeth of Gear 22 are concave, allowing for better interaction with the threads of the worm shaft 20. The worm’s lead angle causes the worm to self-lock, preventing reverse motion. However, this self-locking mechanism is not entirely dependable. Worm gears are used in numerous industrial applications, from elevators to fishing reels and automotive power steering.

The new gear is installed on a shaft that is secured in an oil seal. To install a new gear, you first need to remove the old gear. Next, you need to unscrew the 2 bolts that hold the gear onto the shaft. Next, you should remove the bearing carrier from the output shaft. Once the worm gear is removed, you need to unscrew the retaining ring. After that, install the bearing cones and the shaft spacer. Make sure that the shaft is tightened properly, but do not over-tighten the plug.

To prevent premature failures, use the right lubricant for the type of worm gear. A high viscosity oil is required for the sliding action of worm gears. In two-thirds of applications, lubricants were insufficient. If the worm is lightly loaded, a low-viscosity oil may be sufficient. Otherwise, a high-viscosity oil is necessary to keep the worm gears in good condition.

Another option is to vary the number of teeth around the gear 22 to reduce the output shaft’s speed. This can be done by setting a specific ratio (for example, 5 or 10 times the motor’s speed) and modifying the worm’s dedendum accordingly. This process will reduce the output shaft’s speed to the desired level. The worm’s dedendum should be adapted to the desired axial pitch.

Worm Shaft 20

When selecting a worm gear, consider the following things to consider. These are high-performance, low-noise gears. They are durable, low-temperature, and long-lasting. Worm gears are widely used in numerous industries and have numerous benefits. Listed below are just some of their benefits. Read on for more information. Worm gears can be difficult to maintain, but with proper maintenance, they can be very reliable.

The worm shaft is configured to be supported in a frame 24. The size of the frame 24 is determined by the center distance between the worm shaft 20 and the output shaft 16. The worm shaft and gear 22 may not come in contact or interfere with 1 another if they are not configured properly. For these reasons, proper assembly is essential. However, if the worm shaft 20 is not properly installed, the assembly will not function.

Another important consideration is the worm material. Some worm gears have brass wheels, which may cause corrosion in the worm. In addition, sulfur-phosphorous EP gear oil activates on the brass wheel. These materials can cause significant loss of load surface. Worm gears should be installed with high-quality lubricant to prevent these problems. There is also a need to choose a material that is high-viscosity and has low friction.

Speed reducers can include many different worm shafts, and each speed reducer will require different ratios. In this case, the speed reducer manufacturer can provide different worm shafts with different thread patterns. The different thread patterns will correspond to different gear ratios. Regardless of the gear ratio, each worm shaft is manufactured from a blank with the desired thread. It will not be difficult to find 1 that fits your needs.

Gear 22’s axial pitch PX

The axial pitch of a worm gear is calculated by using the nominal center distance and the Addendum Factor, a constant. The Center Distance is the distance from the center of the gear to the worm wheel. The worm wheel pitch is also called the worm pitch. Both the dimension and the pitch diameter are taken into consideration when calculating the axial pitch PX for a Gear 22.

The axial pitch, or lead angle, of a worm gear determines how effective it is. The higher the lead angle, the less efficient the gear. Lead angles are directly related to the worm gear’s load capacity. In particular, the angle of the lead is proportional to the length of the stress area on the worm wheel teeth. A worm gear’s load capacity is directly proportional to the amount of root bending stress introduced by cantilever action. A worm with a lead angle of g is almost identical to a helical gear with a helix angle of 90 deg.

In the present invention, an improved method of manufacturing worm shafts is described. The method entails determining the desired axial pitch PX for each reduction ratio and frame size. The axial pitch is established by a method of manufacturing a worm shaft that has a thread that corresponds to the desired gear ratio. A gear is a rotating assembly of parts that are made up of teeth and a worm.

In addition to the axial pitch, a worm gear’s shaft can also be made from different materials. The material used for the gear’s worms is an important consideration in its selection. Worm gears are usually made of steel, which is stronger and corrosion-resistant than other materials. They also require lubrication and may have ground teeth to reduce friction. In addition, worm gears are often quieter than other gears.

Gear 22’s tooth parameters

A study of Gear 22’s tooth parameters revealed that the worm shaft’s deflection depends on various factors. The parameters of the worm gear were varied to account for the worm gear size, pressure angle, and size factor. In addition, the number of worm threads was changed. These parameters are varied based on the ISO/TS 14521 reference gear. This study validates the developed numerical calculation model using experimental results from Lutz and FEM calculations of worm gear shafts.

Using the results from the Lutz test, we can obtain the deflection of the worm shaft using the calculation method of ISO/TS 14521 and DIN 3996. The calculation of the bending diameter of a worm shaft according to the formulas given in AGMA 6022 and DIN 3996 show a good correlation with test results. However, the calculation of the worm shaft using the root diameter of the worm uses a different parameter to calculate the equivalent bending diameter.

The bending stiffness of a worm shaft is calculated through a finite element model (FEM). Using a FEM simulation, the deflection of a worm shaft can be calculated from its toothing parameters. The deflection can be considered for a complete gearbox system as stiffness of the worm toothing is considered. And finally, based on this study, a correction factor is developed.

For an ideal worm gear, the number of thread starts is proportional to the size of the worm. The worm’s diameter and toothing factor are calculated from Equation 9, which is a formula for the worm gear’s root inertia. The distance between the main axes and the worm shaft is determined by Equation 14.

Gear 22’s deflection

To study the effect of toothing parameters on the deflection of a worm shaft, we used a finite element method. The parameters considered are tooth height, pressure angle, size factor, and number of worm threads. Each of these parameters has a different influence on worm shaft bending. Table 1 shows the parameter variations for a reference gear (Gear 22) and a different toothing model. The worm gear size and number of threads determine the deflection of the worm shaft.

The calculation method of ISO/TS 14521 is based on the boundary conditions of the Lutz test setup. This method calculates the deflection of the worm shaft using the finite element method. The experimentally measured shafts were compared to the simulation results. The test results and the correction factor were compared to verify that the calculated deflection is comparable to the measured deflection.

The FEM analysis indicates the effect of tooth parameters on worm shaft bending. Gear 22’s deflection on Worm Shaft can be explained by the ratio of tooth force to mass. The ratio of worm tooth force to mass determines the torque. The ratio between the 2 parameters is the rotational speed. The ratio of worm gear tooth forces to worm shaft mass determines the deflection of worm gears. The deflection of a worm gear has an impact on worm shaft bending capacity, efficiency, and NVH. The continuous development of power density has been achieved through advancements in bronze materials, lubricants, and manufacturing quality.

The main axes of moment of inertia are indicated with the letters A-N. The three-dimensional graphs are identical for the seven-threaded and one-threaded worms. The diagrams also show the axial profiles of each gear. In addition, the main axes of moment of inertia are indicated by a white cross.