Product Description

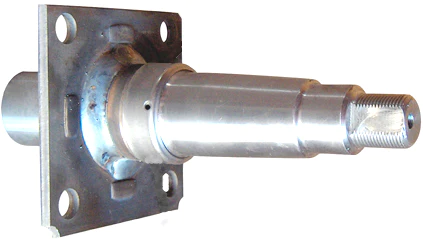

Trailer Axle Replacement Spindle

| Part No. | Overall Length | Diameter Weld Tube | Long Weld Stub |

| HTA103 | 7″ | 1 1/4″ | 2 1/4″ |

Product Specifications:

7″ Overall Length

1 1/4″ Diameter Weld Tube

2 1/4″ Long Weld Stub

HangZhou CHINAMFG Machinery Co., Ltd is a professional manufacturer of trailer parts in HangZhou, ZHangZhoug Province, China since 2016.

We can produce many trailer parts & accessories as follows: Towbars, axles, brake drums, hubs, brake disc, bearings, springs and springs and suspension kits, couplings, mudguards, U-Bolts, Jockey Wheels, keel rollers and brackets, wobble roller, wheel spacer, equalizers and all accessories related to trailers.

If you can send me the drawings or specifications of the trailer parts, mechanical parts and wheels, we can give you our price.

Welcome to enquiry and email me,thanks!

Q1: Do you have factory?

A: Yes, we have our own factory, own engineers, we can meet custom’s unique requirement.

Q2: Can I have a sample order?

A: Yes, welcome sample order to test and check quality. Mixed samples are acceptable.

Q3: It’s OK to print my logo on your product?

A: Yes, we can according to your exact requirement.

Q4:How do you ship the goods and how long does it take arrive?

A: We usually shipped by DHL, UPS, FedEx, it usually takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5: What is your advantages?

A: We are professional supplier for more than 10 years, we always put the quality and price at the first place. At the same time, our products are exported to various countries, we have full experience to solve thorny problems.

1-Welcome OEM

- You can use your own brands or ours, if you use our brand, our professional team will help you design the packing.

2-Our service

- You inquiry related to our products or prices will be replied in 24 hours.

- Well-trained and experienced staffs to answer all your enquirys in fluent English.

- Protection of your sales area, ideas of your design and all your private information.

- We have a QC team, every product will be checked by them before packed.

3-Welcome to visit

- When you come to our company visit us, we will arrange a car for picking up and help you book hotel. If you want to visit the local scenic spot, our colleague will accompany you.

4-Warranty

- Customer should be provide the video and the pictures for the problem products.

- Products returned within the warranty period must bear product number & date code.

5-After service

- In production and after delivery, we will track on time and tell you goods situation.

- When the goods arrived, if you find any design and quality questions, or difference from your samples, please feel free to contact us, we will find the question and solve it with you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Axle Number: | 1 |

| Application: | Trailer |

| Samples: |

US$ 3.8/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there innovations or advancements in trailer spindle technology that have emerged recently?

Yes, there have been notable innovations and advancements in trailer spindle technology that have emerged recently. Here’s a detailed explanation:

Trailer spindle technology has continued to evolve to improve the performance, durability, and safety of trailers. Some of the recent innovations and advancements include:

- Sealed Bearing Systems: Sealed bearing systems have become increasingly popular in trailer spindle technology. These systems feature integrated seals that provide enhanced protection against contaminants such as dirt, water, and debris. The sealed design helps to prolong the life of the bearings by reducing the risk of premature wear and damage. It also minimizes maintenance requirements by eliminating the need for regular bearing re-greasing.

- Improved Bearing Materials: Recent advancements have led to the development of advanced bearing materials for trailer spindles. Materials such as ceramic and advanced polymers offer superior strength, corrosion resistance, and durability compared to traditional steel bearings. These advanced bearing materials contribute to extended bearing life, reduced friction, and improved overall performance of the trailer spindles.

- High-Strength Spindle Construction: Manufacturers have been focusing on improving the strength and durability of trailer spindles. This includes the use of high-strength materials such as forged steel or alloy steel in the construction of spindles. These materials provide increased load capacity, enhanced resistance to bending or deformation, and improved structural integrity, ensuring reliable and safe towing operations.

- Intelligent Monitoring Systems: Some advancements in trailer spindle technology have introduced intelligent monitoring systems. These systems utilize sensors and advanced electronics to monitor spindle performance in real-time. They can detect abnormalities such as excessive heat, vibration, or bearing wear and provide early warning alerts to the operator. Intelligent monitoring systems help prevent potential failures, reduce downtime, and enhance overall safety during towing.

- Enhanced Corrosion Resistance: With a focus on improving the longevity of trailer spindles, advancements have been made in enhancing corrosion resistance. This includes the use of specialized coatings, surface treatments, or materials that provide superior protection against corrosion caused by factors like moisture, salt, or harsh environmental conditions. Enhanced corrosion resistance helps to prolong the lifespan of the spindles and ensures their optimal functionality over an extended period.

These recent innovations and advancements in trailer spindle technology have contributed to improved performance, increased durability, and enhanced safety in towing systems. They address common challenges such as bearing maintenance, corrosion, load capacity, and monitoring, providing trailer owners with more reliable and efficient options for their towing needs.

It’s important to note that the availability and implementation of these advancements may vary among different manufacturers and models of trailers. When considering the latest innovations in trailer spindle technology, it’s advisable to consult with manufacturers, industry experts, or trusted suppliers to explore the specific features and benefits offered by different spindle systems.

What advantages do certain types of trailer spindles offer compared to others?

Trailer spindles come in various types, and each type offers unique advantages compared to others. Here’s a detailed explanation:

- Straight Spindles:

Straight spindles are the most common type and offer several advantages:

- Cost-Effective: Straight spindles are relatively simple in design and construction, making them cost-effective compared to other types.

- Wide Availability: Straight spindles are widely available, making them easy to find and replace if needed.

- Easy Maintenance: Straight spindles are relatively easy to maintain and service, requiring fewer specialized tools or techniques.

- Tapered Spindles:

Tapered spindles provide their own set of advantages:

- Increased Load Capacity: Tapered spindles are designed to handle higher load capacities compared to straight spindles of similar size. The tapered shape enhances their strength and load-bearing capabilities.

- Better Alignment: Tapered spindles offer improved wheel alignment as they allow for precise fitment of the wheel hub assembly. This helps in maintaining proper tracking and reduces tire wear.

- Enhanced Stability: The taper design of these spindles contributes to enhanced stability during towing, reducing the risk of wheel wobbling or vibrations.

- Drop Spindles:

Drop spindles offer specific advantages for certain trailer applications:

- Lowered Trailer Height: Drop spindles are designed to lower the trailer’s ride height, allowing for easier loading and unloading of cargo or equipment.

- Improved Ground Clearance: By lowering the trailer height, drop spindles can also improve ground clearance, reducing the risk of bottoming out on uneven terrain.

- Enhanced Aerodynamics: The lower trailer height achieved with drop spindles can improve aerodynamics, leading to potential fuel efficiency gains.

- Brake Spindles:

Brake spindles offer advantages when used with trailer braking systems:

- Integrated Braking: Brake spindles are designed to accommodate brake assemblies and provide a mounting point for the brake components, allowing for integrated braking systems.

- Improved Stopping Power: Brake spindles, when used with appropriate brake systems, enhance the trailer’s stopping power, improving overall safety during towing.

- Controlled Braking: Brake spindles provide better control and modulation of braking forces, allowing for smoother and more controlled stops.

It’s important to note that the advantages of certain types of trailer spindles may be more relevant to specific trailer applications or towing requirements. Consideration should also be given to factors such as load capacity, compatibility with other trailer components, and manufacturer recommendations when selecting the appropriate spindle type for a given application.

In summary, certain types of trailer spindles offer advantages over others. Straight spindles are cost-effective, widely available, and easy to maintain. Tapered spindles provide increased load capacity, better alignment, and enhanced stability. Drop spindles lower the trailer height, improve ground clearance, and enhance aerodynamics. Brake spindles offer integrated braking, improved stopping power, and controlled braking. Understanding the advantages of different spindle types helps in selecting the most suitable option based on specific trailer requirements and towing needs.

Can you explain the primary functions and importance of trailer spindles in towing?

Trailer spindles play crucial functions and hold significant importance in towing operations. Here’s a detailed explanation of the primary functions and importance of trailer spindles in towing:

- Wheel Attachment:

The primary function of a trailer spindle in towing is to provide a secure attachment point for the trailer wheels. The spindle is designed to fit into the wheel hub assembly and allows for the installation of the wheels. It typically utilizes lug nuts or bolts to secure the wheel tightly to the spindle, ensuring that it remains in place during towing.

- Load Bearing:

Trailer spindles bear the weight of the trailer and its cargo. As the trailer moves, the weight is transferred from the trailer’s frame and axle to the wheels through the spindles. The spindles distribute the load evenly across the axle, ensuring that the weight is adequately supported. It is crucial for the spindles to be strong enough to handle the weight and forces exerted on the wheels during towing.

- Wheel Rotation:

Another essential function of trailer spindles is to facilitate the rotation of the wheels. As the towing vehicle moves forward, the spindles transfer the rotational force from the trailer axle to the wheel hubs, allowing the wheels to rotate freely. This rotation enables the trailer to move smoothly and maneuver effectively.

- Lubrication and Heat Dissipation:

Trailer spindles may incorporate features for lubrication and heat dissipation. Proper lubrication is essential to reduce friction and wear between the spindle and the wheel hub, ensuring smooth wheel rotation and minimizing the risk of damage. Some spindles include grease or oil seals and fittings that allow for regular lubrication. Additionally, the spindle’s design often includes mechanisms to dissipate heat generated during towing. Effective heat dissipation helps prevent excessive heat buildup, which can lead to component failure.

- Maintaining Stability and Control:

The proper functioning of trailer spindles is crucial for maintaining stability and control during towing. The secure attachment of the wheels to the spindles ensures that they remain in place, preventing wheel separation or instability. The even distribution of weight across the spindles promotes balanced towing, minimizing the risk of swaying or fishtailing. The smooth rotation of the wheels facilitated by the spindles enables precise maneuvering and control of the trailer.

- Overall Safety:

The importance of trailer spindles in towing cannot be overstated in terms of safety. Reliable and properly functioning spindles contribute to the overall safety of the towing operation. By securely attaching the wheels and maintaining stability, they help prevent accidents or incidents caused by wheel detachment, loss of control, or trailer instability. Proper lubrication and heat dissipation also minimize the risk of mechanical failures or damage that could compromise safety.

In summary, trailer spindles serve primary functions and hold significant importance in towing. They provide a secure attachment point for the wheels, bear the weight of the trailer and cargo, facilitate wheel rotation, allow for lubrication and heat dissipation, maintain stability and control, and contribute to overall towing safety. Choosing high-quality spindles and ensuring their proper maintenance and functionality are crucial for safe and efficient towing operations.

editor by CX 2024-03-09