Product Description

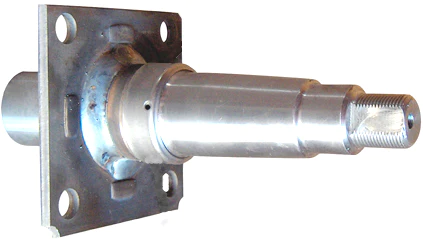

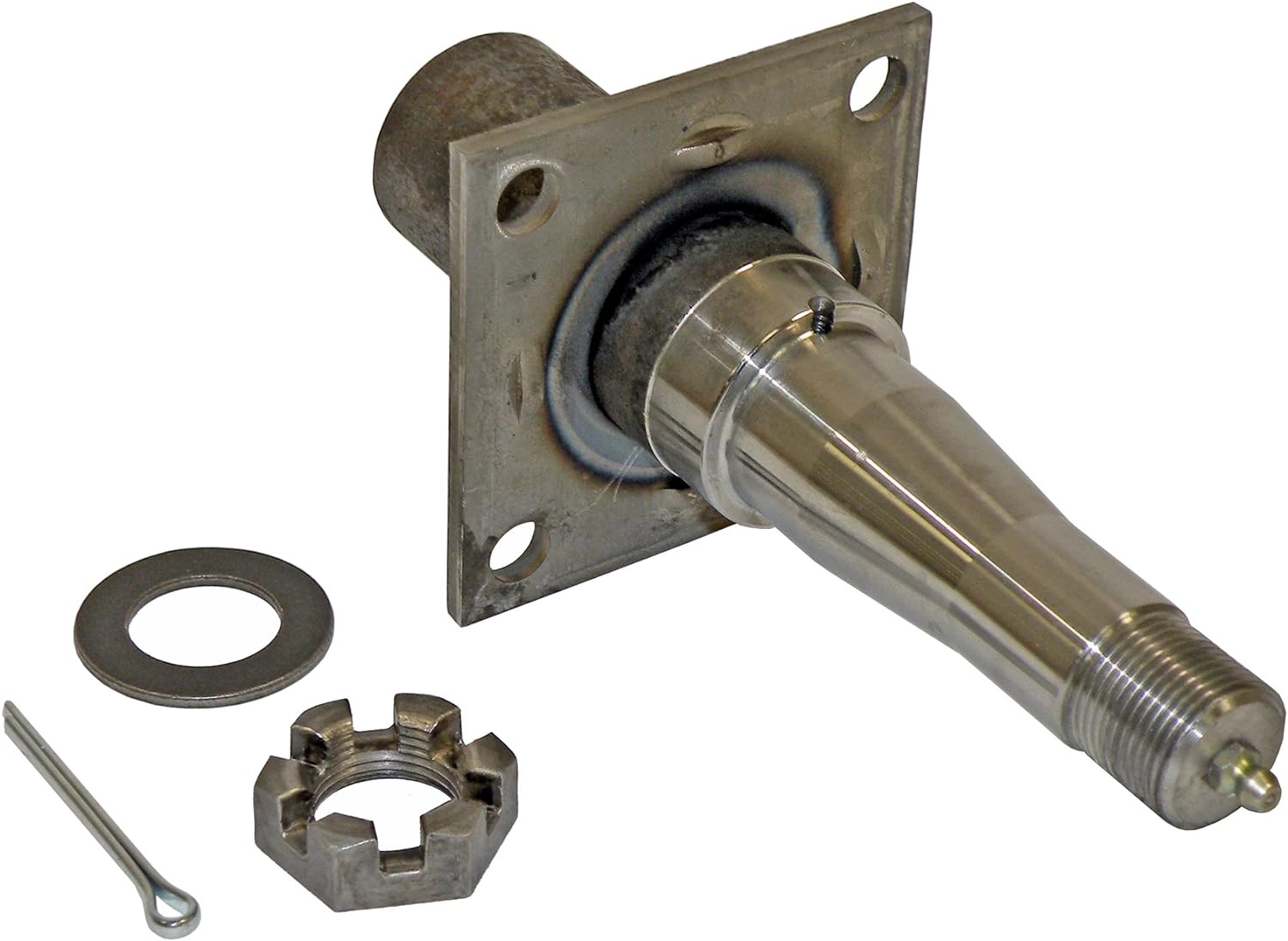

1750lbs 3500lbs Capacity Trailer Steel Forging Drop Spindles for Axle Parts

Wide range of sizes with quality stub axles available. Axles are very easy to replace. Sturdy steel construction to ensure durability.

| Part Number | Description | Capacity | Brake Flange | Bearings ID | Bearings no. | Stub Length | Grease Seal ID |

| S1008 | Round Spindle Dia.1.25″,BT8 | 1000 lbs | W/O | 1″x1″ | L44643 x2 | Customized | 1.24″ |

| S1016 | Round Spindle Dia.1.25″,BT16 | 1000 lbs | W/O | 1.06″x1.06″ | L44649 x2 | Customized | 1.24″ |

| S125016 | Round Spindle Dia.1.57″,BT16 | 1250 lbs | W/O | 1.06″x1.06″ | L44649 x2 | Customized | 1.5″ |

| S175084 | Round Spindle Dia.1.75″,#84 | 1750 lbs | W/O | 1.38″x1.06″ | L68149 x L44649 | Customized | 1.73″ |

| S3042 | Round Spindle Dia.2.25″,#42 | 3000 lbs | W/O | 1.74″x1.25″ | 25580 x 15123 | Customized | 2.24″ |

| S175084F | Round Spindle Dia.1.75″,#84 | 1750 lbs | Yes | 1.38″x1.06″ | L68149 x L44649 | Customized | 1.73″ |

| S3042F | Round Spindle Dia.2.25″,#42 | 3000 lbs | Yes | 1.74″x1.25″ | 25580 x 15123 | Customized | 2.24″ |

| S750R39 | 39mm Round Stub Axle | 750 kg/pr | W/O | LM Bearings | LM67048 x LM11949 | Customized | 36.5mm |

| S10S40 | 40mm Square Stub Axle | 1000 kg/pr | W/O | LM Bearings | LM67048 x LM11949 | Customized | 36.5mm |

| S1250S45 | 45mm Square Stub Axle | 1250 kg/pr | W/O | SL Bearings | L68149 x LM12749 | Customized | 42mm |

| S1250R50 | 50mm Round Stub Axle | 1250 kg/pr | W/O | SL Bearings | L68149 x LM12749 | Customized | 42mm |

| S15S45 | 45mm Square Stub Axle | 1500 kg/pr | W/O | 1.5T Bearings | LM29749 x L44649 | Customized | 44.45mm |

| S15R50 | 50mm Round Stub Axle | 1500 kg/pr | W/O | 1.5T Bearings | LM29749 x L44649 | Customized | 44.45mm |

| S15S45P | 45mm Square Stub Axle Parallel | 1500 kg/pr | W/O | Parallel | L68149 x L68149 | Customized | 42mm |

| S20S50 | 50mm Square Stub Axle | 2000 kg/pr | W/O | 2.0T Bearings | 25580 x LM67048 | Customized | 55mm |

| S20R56 | 56mm Round Stub Axle | 2000 kg/pr | W/O | 2.0T Bearings | 25580 x LM67048 | Customized | 55mm |

| S30R63 | 63mm Round Stub Axle | 3000 kg/pr | W/O | 3.0T Bearings | 35710 x LM29749 | Customized | 61mm |

1) Do you have factory?

Stone :

Yes, we have our own factory, own engineers, we can meet custom’s unique requirement.

2) Do you provide sample? Free or charge?

Stone :

Sample can be submitted for clients check and approval ; Normal sample will be take cost and can be consider to return back since order be placed.

3) What is your MOQ?

Stone :

MOQ 1-200 for trailer axles & hubs.

MOQ 3000 for trailer parts assembly

4) Can you manufacture the parts according to our size?

Stone :

Depend on make tooling we can support your to be achieved your fixed request size for items.

5) What is your term of payment?

Stone :

Normally for bulk TT., Irrevocable L/C at sight will be workable.

For samples , Paypal can be accept.

6) How long is your delivery time?

Stone :

Normal 25 working days for delivery ;

CHINAMFG time be about 35 working days.

7) Can I delivery the goods from other supplier to your factory? Then load together?

Stone :

Sure ,we can accept and support. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small (28-55mm) |

| Material: | Steel, Alloy |

| Spherical: | Aligning Bearings |

| Load Direction: | Axial Bearing |

| Customization: |

Available

|

|

|---|

Can you explain the role of bearings in conjunction with trailer spindles in towing systems?

Trailer bearings play a critical role in conjunction with trailer spindles in towing systems. Here’s an explanation of their role:

Trailer bearings are components that facilitate the smooth rotation of the trailer wheels around the spindles. They are located within the hub assembly and provide a low-friction interface between the stationary spindle and the rotating wheel. The bearings allow the trailer wheels to rotate freely while supporting the weight of the trailer and its cargo.

The primary functions of bearings in conjunction with trailer spindles are:

- Load Support: Bearings bear the weight of the trailer and its cargo, transferring the load from the axle to the wheels. They distribute the load evenly across the spindle, preventing excessive stress on any specific area and ensuring optimal load capacity.

- Reducing Friction: Bearings minimize friction between the stationary spindle and the rotating wheel hub. By providing a smooth, low-friction interface, they allow the wheels to rotate freely with minimal resistance. This reduces energy consumption and promotes efficient towing.

- Alignment and Stability: Bearings help maintain proper alignment and stability of the trailer wheels. They ensure that the wheels rotate in a straight line and prevent wobbling or uneven tire wear. This is crucial for safe and controlled towing, as improper wheel alignment can lead to handling issues and compromised stability.

- Shock Absorption: Bearings also play a role in absorbing shocks and vibrations encountered during towing. They provide a cushioning effect, reducing the impact of bumps and irregularities on the trailer wheels. This helps improve overall ride comfort and protects the trailer and its contents from excessive jolts or vibrations.

- Lubrication: Properly lubricated bearings reduce friction and heat generation. They also help prevent premature wear and damage to the bearing surfaces. Lubrication ensures smooth operation and extends the lifespan of the bearings and the overall functionality of the towing system.

It’s important to note that trailer bearings require regular maintenance, including inspection, cleaning, and lubrication, to ensure their optimal performance and longevity. Neglecting bearing maintenance can lead to overheating, premature wear, and ultimately, bearing failure, which can result in costly repairs and unsafe towing conditions.

When selecting bearings for trailer spindles, it’s crucial to choose high-quality bearings that are appropriate for the load capacity and towing conditions. It’s recommended to follow the manufacturer’s guidelines regarding bearing specifications, lubrication intervals, and maintenance procedures to ensure proper functioning of the bearings in conjunction with the trailer spindles.

In summary, trailer bearings are essential components in towing systems that work in conjunction with trailer spindles. They support the load, reduce friction, maintain alignment and stability, absorb shocks, and require regular maintenance to ensure optimal functionality and safe towing operations.

What advantages do certain types of trailer spindles offer compared to others?

Trailer spindles come in various types, and each type offers unique advantages compared to others. Here’s a detailed explanation:

- Straight Spindles:

Straight spindles are the most common type and offer several advantages:

- Cost-Effective: Straight spindles are relatively simple in design and construction, making them cost-effective compared to other types.

- Wide Availability: Straight spindles are widely available, making them easy to find and replace if needed.

- Easy Maintenance: Straight spindles are relatively easy to maintain and service, requiring fewer specialized tools or techniques.

- Tapered Spindles:

Tapered spindles provide their own set of advantages:

- Increased Load Capacity: Tapered spindles are designed to handle higher load capacities compared to straight spindles of similar size. The tapered shape enhances their strength and load-bearing capabilities.

- Better Alignment: Tapered spindles offer improved wheel alignment as they allow for precise fitment of the wheel hub assembly. This helps in maintaining proper tracking and reduces tire wear.

- Enhanced Stability: The taper design of these spindles contributes to enhanced stability during towing, reducing the risk of wheel wobbling or vibrations.

- Drop Spindles:

Drop spindles offer specific advantages for certain trailer applications:

- Lowered Trailer Height: Drop spindles are designed to lower the trailer’s ride height, allowing for easier loading and unloading of cargo or equipment.

- Improved Ground Clearance: By lowering the trailer height, drop spindles can also improve ground clearance, reducing the risk of bottoming out on uneven terrain.

- Enhanced Aerodynamics: The lower trailer height achieved with drop spindles can improve aerodynamics, leading to potential fuel efficiency gains.

- Brake Spindles:

Brake spindles offer advantages when used with trailer braking systems:

- Integrated Braking: Brake spindles are designed to accommodate brake assemblies and provide a mounting point for the brake components, allowing for integrated braking systems.

- Improved Stopping Power: Brake spindles, when used with appropriate brake systems, enhance the trailer’s stopping power, improving overall safety during towing.

- Controlled Braking: Brake spindles provide better control and modulation of braking forces, allowing for smoother and more controlled stops.

It’s important to note that the advantages of certain types of trailer spindles may be more relevant to specific trailer applications or towing requirements. Consideration should also be given to factors such as load capacity, compatibility with other trailer components, and manufacturer recommendations when selecting the appropriate spindle type for a given application.

In summary, certain types of trailer spindles offer advantages over others. Straight spindles are cost-effective, widely available, and easy to maintain. Tapered spindles provide increased load capacity, better alignment, and enhanced stability. Drop spindles lower the trailer height, improve ground clearance, and enhance aerodynamics. Brake spindles offer integrated braking, improved stopping power, and controlled braking. Understanding the advantages of different spindle types helps in selecting the most suitable option based on specific trailer requirements and towing needs.

What is a trailer spindle, and what role does it play in a trailer’s construction?

A trailer spindle is a crucial component in the construction of a trailer. It serves a vital role in supporting and facilitating the movement of the trailer’s wheels. Here’s a detailed explanation of what a trailer spindle is and its significance in a trailer’s construction:

A trailer spindle is a shaft-like component that connects the trailer axle to the wheel hub. It is typically made of high-strength steel and is responsible for supporting the weight of the trailer and facilitating the rotation of the wheels. The spindle is mounted within the wheel hub assembly and allows the wheel to rotate smoothly and securely.

The trailer spindle performs several important functions:

- Wheel Attachment: The spindle provides a secure attachment point for the trailer wheels. It is designed to fit into the wheel hub assembly and is often tapered to ensure a tight and reliable connection. The wheel is typically mounted on the spindle using lug nuts or bolts, which secure it in place.

- Load Bearing: The trailer spindle bears the weight of the trailer and its cargo. It transfers the load from the trailer’s frame and axle to the wheels, distributing the weight evenly across the axle. The spindle must be strong enough to withstand the weight and forces exerted on the wheels during trailer operation.

- Wheel Rotation: The spindle allows the trailer wheels to rotate freely. As the trailer moves, the spindle transfers the rotational force from the axle to the wheel hub, enabling the wheels to spin. This rotation is essential for the trailer’s mobility and maneuverability.

- Lubrication and Heat Dissipation: Some trailer spindles incorporate grease or oil seals and fittings to allow for lubrication. Proper lubrication reduces friction and wear between the spindle and the wheel hub, enhancing the overall performance and lifespan of the trailer’s wheels. Additionally, the spindle’s design facilitates heat dissipation, helping to prevent excessive heat buildup that can lead to component failure.

In summary, a trailer spindle is a vital component in a trailer’s construction. It serves as the connection between the axle and the wheel hub, providing a secure attachment point for the wheels and supporting the weight of the trailer. The spindle enables the wheels to rotate freely, facilitating the trailer’s mobility. It may also incorporate features for lubrication and heat dissipation to ensure proper functioning and longevity of the trailer’s wheels. Overall, the trailer spindle plays a critical role in maintaining the stability, safety, and performance of the trailer during operation.

editor by CX 2024-01-19