Product Description

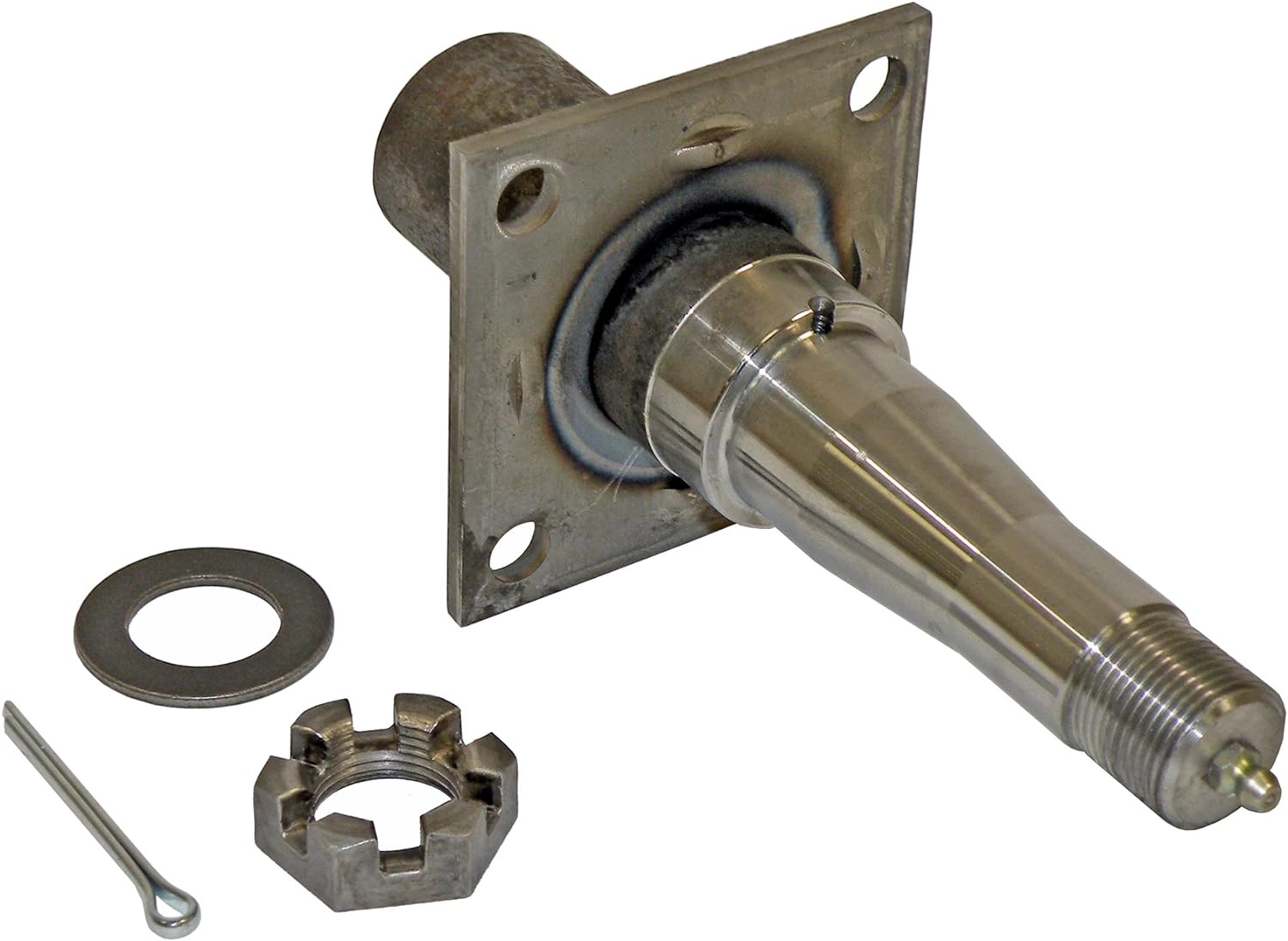

Axle Stub Trailer Axle Spindle with 4-Hole Brake Mounting Flange

| Part NO | Weight | A | B | C | D | E | F | H |

| TA049 | 2.00LBS | 1.31″ | N/A | 5.96″ | 1.25″ | 0.999″ | 0.999″ | 1.75″ |

| TA050 | 2.26LBS | 1.31″ | 1.63″ | 6.68″ | 1.25″ | 0.999″ | 0.999″ | 1.75″ |

| TA051 | 2.25LBS | 1.31″ | N/A | 5.96″ | 1.50″ | 1.602″ | 1.602″ | 1.75″ |

| TA052 | 2.50LBS | 1.31″ | 1.63″ | 6.68″ | 1.50″ | 1.602″ | 1.602″ | 1.75″ |

Trailer parts to suit a complete axle rebuild or partial replacement.

- Hub kits to fit on a new or existing trailer axle

- Hub and stub kits that also include a weld on stub axle

- Braked or non braked hubs, disc brakes or drum brakes to suit a range of applications

- Wireless trailer brake controller systems

- Non-braked hubs and braked hub options

- Comprehensive spare parts, such as brake pads, stub axles, seal kits etc

HangZhou CHINAMFG Machinery Co., Ltd is a professional manufacturer of trailer parts in HangZhou, ZHangZhoug Province, China since 2016.

We can produce many trailer parts & accessories as follows: Towbars, axles, brake drums, hubs, brake disc, bearings, springs and springs and suspension kits, couplings, mudguards, U-Bolts, Jockey Wheels, keel rollers and brackets, wobble roller, wheel spacer, equalizers and all accessories related to trailers.

If you can send me the drawings or specifications of the trailer parts, mechanical parts and wheels, we can give you our price.

Q1: Do you have factory?

A: Yes, we have our own factory, own engineers, we can meet custom’s unique requirement.

Q2: Can I have a sample order?

A: Yes, welcome sample order to test and check quality. Mixed samples are acceptable.

Q3: It’s OK to print my logo on your product?

A: Yes, we can according to your exact requirement.

Q4:How do you ship the goods and how long does it take arrive?

A: We usually shipped by DHL, UPS, FedEx, it usually takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5: What is your advantages?

A: We are professional supplier for more than 10 years, we always put the quality and price at the first place. At the same time, our products are exported to various countries, we have full experience to solve thorny problems.

If you want to know about our products and us, welcome to enquiry and email me.thanks

1-Welcome OEM

- You can use your own brands or ours, if you use our brand, our professional team will help you design the packing.

2-Our service

- You inquiry related to our products or prices will be replied in 24 hours.

- Well-trained and experienced staffs to answer all your enquirys in fluent English.

- Protection of your sales area, ideas of your design and all your private information.

- We have a QC team, every product will be checked by them before packed.

3-Welcome to visit

- When you come to our company visit us, we will arrange a car for picking up and help you book hotel. If you want to visit the local scenic spot, our colleague will accompany you.

4-Warranty

- Customer should be provide the video and the pictures for the problem products.

- Products returned within the warranty period must bear product number & date code.

5-After service

- In production and after delivery, we will track on time and tell you goods situation.

- When the goods arrived, if you find any design and quality questions, or difference from your samples, please feel free to contact us, we will find the question and solve it with you.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Axle Number: | 2 |

| Application: | Trailer |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you provide insights into the importance of proper installation and alignment of trailer spindles?

Proper installation and alignment of trailer spindles are of utmost importance for the safe and efficient operation of trailers. Here’s a detailed explanation:

1. Safety: Ensuring the proper installation and alignment of trailer spindles is crucial for maintaining safe towing conditions. When spindles are installed correctly, they provide structural integrity and stability to the trailer. Proper alignment ensures that the wheels track straight and true, reducing the risk of swaying, fishtailing, or loss of control while towing. Incorrect installation or misalignment can lead to handling issues, increased risk of accidents, and compromised safety for both the driver and other road users.

2. Load Distribution: Properly installed and aligned trailer spindles contribute to effective load distribution. They help evenly distribute the weight of the trailer and its cargo across the axles and wheels. This balanced distribution minimizes excessive stress on specific components, such as tires, suspension, and bearings, ensuring their optimal performance and longevity. Improper installation or misalignment can lead to uneven weight distribution, which may result in premature wear, tire blowouts, or other mechanical failures.

3. Tire Wear: Correct spindle installation and alignment play a significant role in reducing tire wear. When the spindles are aligned properly, the trailer wheels track in a straight line, resulting in even tire wear. Misalignment, on the other hand, can cause irregular tire wear patterns, such as cupping or feathering, which decrease tire lifespan and performance. Proper alignment of spindles helps to maximize tire longevity and maintain optimal traction and handling characteristics.

4. Bearing Performance: Trailer spindles directly impact the performance and lifespan of the bearings. Proper installation ensures that the spindles are securely attached to the trailer frame, providing a stable platform for the bearings. Misalignment or inadequate installation can cause excessive stress on the bearings, leading to premature wear, overheating, and potential bearing failure. Proper alignment and installation of spindles help to maintain the bearings’ integrity, ensuring smooth rotation, reduced friction, and optimal load support.

5. Fuel Efficiency: Properly installed and aligned spindles can contribute to improved fuel efficiency. When the trailer wheels are properly aligned, they experience reduced rolling resistance, resulting in lower energy consumption and improved fuel economy. Misalignment can cause increased rolling resistance, leading to higher fuel consumption during towing.

6. Handling and Stability: Correct spindle installation and alignment contribute to the overall handling and stability of the trailer. Proper alignment ensures that the trailer tracks in a straight line, allowing for predictable and controlled towing. Misalignment can cause the trailer to pull to one side, leading to unstable towing conditions, reduced maneuverability, and potential loss of control.

7. Longevity and Cost Savings: Proper installation and alignment of trailer spindles contribute to the longevity of various trailer components, including tires, bearings, suspension systems, and axles. By minimizing excessive wear, stress, and premature failures, proper alignment and installation help to extend the lifespan of these components. This leads to cost savings in terms of reduced maintenance, repairs, and replacement of parts.

It’s important to follow the manufacturer’s guidelines and recommendations for the installation and alignment of trailer spindles. This may involve using proper tools, torque specifications, and alignment procedures. Seeking professional assistance or consulting with experienced professionals can also ensure accurate installation and alignment, especially when dealing with complex trailer configurations or modifications.

Overall, proper installation and alignment of trailer spindles are vital for safety, load distribution, tire wear, bearing performance, fuel efficiency, handling, stability, longevity, and cost savings. By paying attention to these critical aspects, trailer owners can optimize the performance and reliability of their towing systems.

How does the choice of materials impact the durability and reliability of trailer spindles?

The choice of materials for trailer spindles has a significant impact on their durability and reliability. Here’s a detailed explanation:

The materials used in the construction of trailer spindles play a crucial role in determining their strength, corrosion resistance, and overall performance. Different materials offer varying levels of durability and reliability in different operating conditions and environments.

- Steel:

Steel is a commonly used material for trailer spindles due to its excellent strength and durability. Steel spindles are known for their ability to withstand heavy loads and provide reliable performance. They are often preferred for applications that require high load capacities, such as commercial trailers or trailers used in demanding industries. Steel spindles can handle rough terrains, frequent use, and challenging towing conditions.

- Aluminum:

Aluminum spindles offer several advantages, including lightweight construction and corrosion resistance. They are commonly used in applications where weight reduction is important, such as recreational trailers or trailers that require improved fuel efficiency. Aluminum spindles provide good durability and reliability while reducing the overall weight of the trailer, which can result in improved towing performance.

- Ductile Iron:

Ductile iron spindles offer a combination of strength, durability, and cost-effectiveness. They are known for their ability to withstand heavy loads and provide reliable performance in various towing applications. Ductile iron spindles are often chosen for their high strength-to-weight ratio and resistance to wear and deformation.

- Composite Materials:

Composite materials, such as fiberglass-reinforced polymers, are gaining popularity in the manufacturing of trailer spindles. These materials offer advantages such as high strength-to-weight ratio, corrosion resistance, and reduced maintenance requirements. Composite spindles can provide excellent durability and reliability while being lighter in weight compared to traditional materials like steel or iron.

When selecting the material for trailer spindles, it’s important to consider the specific requirements of the towing application. Factors such as load capacity, operating conditions, and environmental factors should be taken into account. Additionally, it’s crucial to follow the manufacturer’s recommendations regarding material selection to ensure compatibility with other trailer components and adherence to safety standards.

In summary, the choice of materials significantly impacts the durability and reliability of trailer spindles. Steel spindles offer excellent strength and durability, while aluminum spindles provide lightweight construction and corrosion resistance. Ductile iron spindles offer a combination of strength and cost-effectiveness. Composite materials offer a lightweight alternative with high strength-to-weight ratios. By selecting the appropriate material based on the specific towing requirements, trailer owners can ensure the longevity, performance, and reliability of their trailer spindles.

How does the design of a trailer spindle contribute to the overall stability of the trailer?

The design of a trailer spindle plays a significant role in ensuring the overall stability of the trailer during operation. Here’s a detailed explanation of how the design of a trailer spindle contributes to trailer stability:

- Secure Wheel Attachment:

The design of the trailer spindle includes features that provide a secure attachment point for the trailer wheels. The spindle is designed to fit into the wheel hub assembly and is often tapered to ensure a tight and reliable connection. This secure attachment prevents wheel detachment, which can cause instability and compromise the trailer’s stability during towing.

- Load Distribution:

The design of the trailer spindle allows for proper load distribution across the axle. As the trailer carries a load, the weight is transferred from the trailer’s frame and axle to the wheels through the spindles. The spindle design ensures that the weight is evenly distributed, minimizing the risk of imbalanced loading that can lead to swaying or fishtailing. Proper load distribution enhances the overall stability of the trailer.

- Strength and Durability:

The design of the spindle takes into account the strength and durability requirements of the trailer. Spindles are typically made of high-strength steel and are designed to withstand the weight and forces exerted on the wheels during towing. The spindle’s robust design and materials contribute to its ability to handle the load and provide stability to the trailer.

- Wheel Alignment:

The design of the spindle also influences the alignment of the trailer wheels. Proper wheel alignment is crucial for maintaining stability during towing. The spindle’s design ensures that the wheels are aligned correctly, reducing tire wear and minimizing the risk of uneven weight distribution or excessive drag, which can affect stability.

- Smooth Wheel Rotation:

The design of the trailer spindle facilitates smooth wheel rotation. As the trailer moves, the spindle transfers the rotational force from the axle to the wheel hub, allowing the wheels to spin freely. Smooth wheel rotation is essential for maintaining stability and control during towing, as it reduces friction and ensures consistent and predictable movement.

- Compatibility with Suspension System:

The design of the spindle takes into consideration the trailer’s suspension system. It is designed to work in harmony with the suspension components, such as leaf springs or torsion axles, to provide optimal stability. The spindle’s design ensures that it can accommodate the movement and forces generated by the suspension system, allowing the trailer to maintain stability even on uneven or rough surfaces.

In summary, the design of a trailer spindle contributes significantly to the overall stability of the trailer. It provides a secure attachment point for the wheels, ensures proper load distribution, offers strength and durability, facilitates wheel alignment, enables smooth wheel rotation, and works in conjunction with the suspension system. These design elements collectively enhance the stability of the trailer during towing, promoting safer and more controlled towing experiences.

editor by CX 2024-01-30