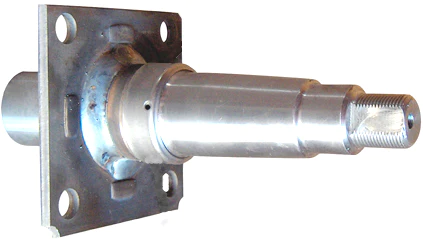

Product Description

Our factory

Loading

FAQ:

Q1: How do you guarantee quality?

A: We take quality inspect records from raw material to finished product.

The former department bear 100% responsibility for next process to guarantee quality.

Q2: Can you produce if we have samples only?

A: Our technical ability is strong enough to deal with different types of spring.

Sample drawing and customers’ interests will be protected well.

Q3: Is it possible to have sample for quality testing?

A: Same or similar sample are available for free.

Q4: What is your MOQ?

A: For common material size, MOQ requires 30~50 pcs;

For special material size, Moq requires 3 ton or more;

Q5: What about the package of the product?

A:The goods will be packed according to your requirements and in well protection before delivery.

Q6: What is your terms of payment?

A: T/T, L/C at sight , Western Union.

Q7: What’s the delivery time ?

A: Most of parts are available in storage. For container delivery, 1 container can finish loading in 10 days.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 6 Month |

|---|---|

| Warranty: | 6 Month |

| Type: | Suspension |

| Certification: | ISO |

| Loading Weight: | 25T |

| ABS: | Without ABS |

| Customization: |

Available

|

|

|---|

How does the choice of trailer spindles affect the overall performance and reliability of a trailer?

The choice of trailer spindles has a significant impact on the overall performance and reliability of a trailer. Here’s a detailed explanation:

- 1. Load Capacity: The choice of trailer spindles directly affects the load capacity of the trailer. Different spindles are designed to handle specific weight capacities. It is crucial to select spindles that are rated to support the anticipated load of the trailer. Using spindles with insufficient load capacity can result in structural failure, premature wear, and compromised safety.

- 2. Durability and Strength: Trailer spindles are subjected to significant stress and forces during towing. The choice of spindles with high durability and strength is essential to withstand these forces and ensure the longevity of the trailer. Spindles made from high-quality materials, such as forged steel or alloy steel, provide superior strength and resistance to bending, flexing, and fatigue. Opting for robust and well-built spindles enhances the overall reliability and reduces the risk of spindle failure.

- 3. Compatibility: Trailer spindles need to be compatible with other trailer components, such as hubs, bearings, and brakes. Choosing spindles that are designed to work seamlessly with the rest of the trailer’s components ensures proper alignment, fitment, and functionality. Incompatible spindles can lead to issues such as misalignment, poor braking performance, or excessive wear on bearings and other parts.

- 4. Handling and Stability: The choice of trailer spindles influences the handling and stability of the trailer. Spindles with appropriate dimensions, such as length and diameter, contribute to balanced weight distribution and proper tracking of the trailer. Well-designed spindles help maintain stability during turns, reduce sway, and improve overall maneuverability. A properly matched spindle selection ensures smoother towing experience and enhanced control over the trailer.

- 5. Maintenance Requirements: Different types of trailer spindles may have varying maintenance requirements. Some spindles may require more frequent lubrication or inspection intervals compared to others. Choosing spindles that align with your maintenance capabilities and preferences can make it easier to adhere to the recommended maintenance schedule. Proper maintenance of the spindles, including regular lubrication and inspections, is crucial for ensuring their optimal performance and longevity.

- 6. Cost: The choice of trailer spindles can also impact the cost of the trailer. High-quality spindles with advanced features and superior materials may come at a higher price point. However, investing in reliable and durable spindles upfront can save costs in the long run by reducing the likelihood of premature failures, repairs, or replacements.

Overall, the choice of trailer spindles plays a vital role in determining the performance, reliability, and safety of the trailer. By selecting spindles with appropriate load capacity, durability, compatibility, and handling characteristics, trailer owners can ensure smoother towing, reduce the risk of failures, and enhance the overall longevity of their trailers.

What maintenance practices are recommended for trailer spindles to ensure optimal functionality?

Proper maintenance of trailer spindles is essential to ensure their optimal functionality and extend their lifespan. Here are some recommended maintenance practices:

- Regular Inspections: Conduct regular visual inspections of the trailer spindles to check for any signs of damage, wear, or corrosion. Look for cracks, bends, or excessive rust that may compromise the spindle’s integrity. Inspect the spindle nuts, bearings, and seals for proper alignment and condition.

- Lubrication: Proper lubrication is crucial for smooth spindle operation and minimizing friction. Follow the manufacturer’s recommendations for lubrication intervals and use a high-quality grease suitable for trailer spindles. Apply grease to the bearings and spindle surfaces as per the instructions, ensuring even distribution.

- Bearing Maintenance: Inspect and repack the wheel bearings regularly to prevent overheating and premature wear. Clean the bearings and races thoroughly, remove old grease, and repack them with fresh grease. Replace worn or damaged bearings promptly to avoid potential failures.

- Seal Inspection: Check the condition of the spindle seals to ensure they provide adequate protection against dirt, water, and contaminants. Replace damaged or worn seals to maintain proper lubrication and prevent moisture ingress, which can lead to bearing damage.

- Torque Checks: Periodically check and adjust the torque of the spindle nuts to ensure proper bearing adjustment. Follow the manufacturer’s specifications for the recommended torque values and tightening sequence. Over-tightened or loose spindle nuts can lead to bearing damage and compromised spindle performance.

- Brake System Maintenance: If the trailer has brake spindles, inspect and maintain the brake system components as per the manufacturer’s recommendations. Check the brake pads, calipers, and brake lines for wear, damage, or leaks. Keep the braking system clean and adjust the brakes as necessary for optimal stopping performance.

- Protection from Environmental Elements: Protect the spindles from harsh environmental conditions, such as excessive moisture, saltwater, or chemicals. If the trailer is exposed to these elements, consider using protective coatings or covers to minimize corrosion and damage.

- Professional Servicing: For complex maintenance tasks or if you’re unsure about any specific maintenance procedure, it’s recommended to seek professional servicing. Trained technicians can perform comprehensive inspections, bearing replacements, or other specialized maintenance tasks to ensure the optimal functionality of the trailer spindles.

Following these maintenance practices will help ensure the optimal functionality and longevity of trailer spindles. Regular inspections, proper lubrication, bearing maintenance, seal inspections, torque checks, brake system maintenance, protection from environmental elements, and professional servicing when needed are all important steps in maintaining trailer spindles in good working condition.

Remember to consult the trailer manufacturer’s guidelines and recommendations for specific maintenance requirements and intervals based on the spindle type and trailer model.

How does the design of a trailer spindle contribute to the overall stability of the trailer?

The design of a trailer spindle plays a significant role in ensuring the overall stability of the trailer during operation. Here’s a detailed explanation of how the design of a trailer spindle contributes to trailer stability:

- Secure Wheel Attachment:

The design of the trailer spindle includes features that provide a secure attachment point for the trailer wheels. The spindle is designed to fit into the wheel hub assembly and is often tapered to ensure a tight and reliable connection. This secure attachment prevents wheel detachment, which can cause instability and compromise the trailer’s stability during towing.

- Load Distribution:

The design of the trailer spindle allows for proper load distribution across the axle. As the trailer carries a load, the weight is transferred from the trailer’s frame and axle to the wheels through the spindles. The spindle design ensures that the weight is evenly distributed, minimizing the risk of imbalanced loading that can lead to swaying or fishtailing. Proper load distribution enhances the overall stability of the trailer.

- Strength and Durability:

The design of the spindle takes into account the strength and durability requirements of the trailer. Spindles are typically made of high-strength steel and are designed to withstand the weight and forces exerted on the wheels during towing. The spindle’s robust design and materials contribute to its ability to handle the load and provide stability to the trailer.

- Wheel Alignment:

The design of the spindle also influences the alignment of the trailer wheels. Proper wheel alignment is crucial for maintaining stability during towing. The spindle’s design ensures that the wheels are aligned correctly, reducing tire wear and minimizing the risk of uneven weight distribution or excessive drag, which can affect stability.

- Smooth Wheel Rotation:

The design of the trailer spindle facilitates smooth wheel rotation. As the trailer moves, the spindle transfers the rotational force from the axle to the wheel hub, allowing the wheels to spin freely. Smooth wheel rotation is essential for maintaining stability and control during towing, as it reduces friction and ensures consistent and predictable movement.

- Compatibility with Suspension System:

The design of the spindle takes into consideration the trailer’s suspension system. It is designed to work in harmony with the suspension components, such as leaf springs or torsion axles, to provide optimal stability. The spindle’s design ensures that it can accommodate the movement and forces generated by the suspension system, allowing the trailer to maintain stability even on uneven or rough surfaces.

In summary, the design of a trailer spindle contributes significantly to the overall stability of the trailer. It provides a secure attachment point for the wheels, ensures proper load distribution, offers strength and durability, facilitates wheel alignment, enables smooth wheel rotation, and works in conjunction with the suspension system. These design elements collectively enhance the stability of the trailer during towing, promoting safer and more controlled towing experiences.

editor by Dream 2024-04-30