Product Description

Products

Name:

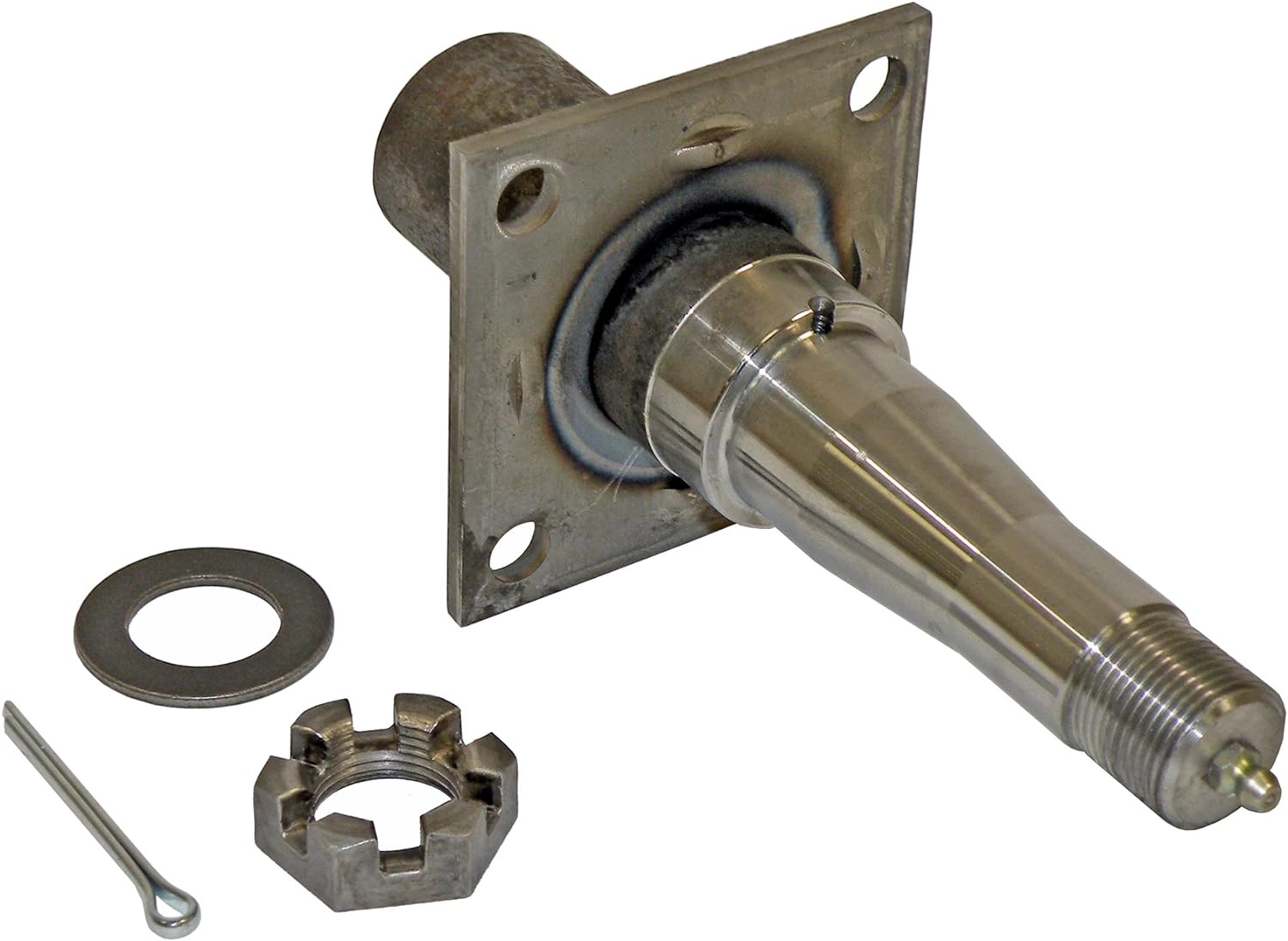

Standard Rgn Drop Forging Spare Parts Forged Alloy Steel Trailer Spindle

Material:

42CrMo

Weight:

From 0.2kg to 10kg

Packing:

Wooden case

Min Order:

1000pcs

Customization:

Customized production is available based on your drawings or sample.

Company Name: HiHangZhou Precision Forging Technology Co., Ltd.

| Process | Die Forging | |||||||||||||

| Material | Stainless Steel, Carbon Steel, Alloy Steel | |||||||||||||

| Weight | 0.1Kg~20Kg | |||||||||||||

| Heat Treatment | Quenching, Annealing,Tempering,Normalizing, Quenching and Tempering | |||||||||||||

| Testing instrument | composition testing | Spectrometer, Metallographic microscope | ||||||||||||

| Performance testing | Hardness tester, Tensile testing machine | |||||||||||||

| Size Measuring | CMM,Micrometer, Vernier Caliper, Depth Caliper, feeler gauge | |||||||||||||

| Thread Gauge , Height Gauge | ||||||||||||||

| Roughness | Ra1.6~Ra6.3 | |||||||||||||

| Machining Equipment | CNC Center , CNC Machines, Turning, Drilling, Milling, boring machine,Grinding Machines, | |||||||||||||

| Wire EDM,Laser Cutting&Welding, Plasma Cutting &Welding, EDM etc. | ||||||||||||||

| Quality control | Sampling inspection of raw materials and semi-finished products, 100% Inspection of finished products | |||||||||||||

| Surface Treatment | Shot Blast , Powder Coating, Polishing, Galvanized , Chrome Plated | |||||||||||||

| 60000T / Years | ||||||||||||||

| Lead Time | Normally 30 – 45 Days. | |||||||||||||

| Payment Terms | T/T , L/C | |||||||||||||

| Material Standard | ASTM , AISI , DIN , BS, JIS, GB, | |||||||||||||

| Certification | ISO9001:2008, IATF16949:2016 | |||||||||||||

HiHangZhou Precision Forging Technology Co., Ltd.

Quality control is a crucial aspect of our production process. Here is an overview of our quality control procedures:

- Incoming raw materials are analyzed using a metallographic microscope to ensure they meet production requirements.

- During production, our QC staff conducts timely sampling to ensure products are defect-free and address any quality issues.

- Our final step involves using a magnetic particle flaw detector to detect hidden defects in metal parts.

- All finished metal parts undergo mechanical performance tests, size measurements, and 100% manual surface inspection in our laboratory.

Below are pictures of the relevant testing equipment:

Welcome to HiHangZhou Precision Forging Technology Co., Ltd.

At HiHangZhou, we adhere to strict quality standards in our Quality Management System Control. Our production site follows ISO9001 and TS16949 quality standards, ensuring the highest level of quality in our products. Additionally, we implement 5S lean production management to optimize efficiency on the production site.

Choose HiHangZhou for precision forging technology you can trust.

Our Advantages:

Brand:

As a subsidiary of the renowned HiHangZhou Group, we have a strong reputation for high-end machinery manufacturing with extensive experience in collaborating with global enterprises.

Technology:

With over 25 years of expertise in forging and casting equipment production, our team of technicians and R&D personnel ensures the highest quality and efficiency in our manufacturing processes.

Service:

We offer custom and standard manufacturing services with a focus on quality, timely delivery, and effective communication throughout the process.

Culture:

Our unique corporate culture fosters individual potential and contributes to the sustainable development of our company.

Social Responsibility:

We are committed to low-carbon environmental protection, energy-saving production, and emission reduction, setting a benchmark for responsible manufacturing practices in our region.

Company Culture

Our Vision

To become 1 of the leading companies.

Our Mission

To become a platform for employees to realize their dreams.

To become a transforming and upgrading pacemaker of Chinese enterprises.

To set national brands with pride.

Our Belief

Strive to build the company into an ideal platform for entrepreneurs to realize their self-worth and contribute to society.

Values

Improvement is innovation, everyone can innovate.

Innovation inspired and failures tolerated.

Frequently Asked Questions

- Q: Are you a trading company or a manufacturer?

A: We are a manufacturer specializing in forging products, casting products, and machining capabilities. - Q: What series products do you offer?

A: We focus on forming processing of ferrous metals through casting, forging, and machining for various industries. - Q: Do you provide samples? Is it free?

A: Yes, we offer samples with customers providing a freight pay-by-account number for cooperation. - Q: Is OEM available?

A: Yes, we offer OEM services. - Q: What’s your quality guarantee?

A: We prioritize continuous improvement in product quality with strict control measures and certifications like ISO/TS16949 and SGS. - Q: How about the Packing?

A: We typically use iron boxes or wooden cases, customizable based on customer preferences. - Q: What is your minimum order quantity?

A: Minimum order quantity varies based on product features such as material, weight, and construction. - Q: What is the lead time?

A: Lead time depends on new die or mold creation, typically within 30-45 days for samples and large batch production. - Q: What payment methods do you accept?

A: We accept payment via T/T or L/C with a 30% deposit in advance and 70% balance against the copy of B/L.

Certification

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Processing Object: | Metal |

|---|---|

| Molding Style: | Forging |

| Molding Technics: | Pressure Casting |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What safety considerations should be taken into account when using trailer spindles in towing?

When using trailer spindles in towing, several safety considerations should be taken into account. Here’s a detailed explanation:

- Proper Installation: Ensure that the trailer spindles are installed correctly according to the manufacturer’s guidelines. This includes securely attaching the spindles to the trailer frame and using appropriate hardware and torque specifications. Improper installation can compromise the structural integrity of the trailer and lead to handling issues or failure during towing.

- Regular Inspection and Maintenance: Regularly inspect the trailer spindles for signs of wear, damage, or misalignment. Check for any cracks, corrosion, or loose components. Additionally, inspect the bearings, seals, and lubrication system to ensure they are in good condition. Perform routine maintenance tasks such as greasing the bearings and replacing worn-out parts as recommended by the manufacturer.

- Proper Weight Distribution: Ensure that the trailer’s load is properly distributed to avoid overloading the spindles or placing excessive stress on specific components. Follow the manufacturer’s guidelines for the trailer’s maximum load capacity and distribute the weight evenly across the axles. Improper weight distribution can lead to instability, reduced braking performance, and increased risk of accidents.

- Appropriate Speed and Driving Behavior: Adhere to safe driving practices when towing a trailer. Maintain a safe and appropriate speed, considering the load, road conditions, and legal limits. Avoid sudden maneuvers, excessive braking, and rapid acceleration, as they can exert additional stress on the spindles and other towing components.

- Tire Maintenance: Properly maintained tires are essential for safe towing. Ensure that the trailer tires are properly inflated, have adequate tread depth, and are in good overall condition. Uneven tire wear or worn-out tires can affect the stability and handling of the trailer, potentially leading to accidents or tire blowouts.

- Proper Hitching and Coupling: Ensure that the trailer is properly hitched and coupled to the towing vehicle. Use a hitch that matches the trailer’s weight capacity, and ensure that the coupling mechanism is engaged securely. Improper hitching or coupling can result in trailer detachment, loss of control, or accidents.

- Trailer Braking System: If the trailer is equipped with brakes, ensure that the braking system is properly maintained and functioning correctly. Regularly inspect and test the brakes to ensure they provide adequate stopping power and are synchronized with the towing vehicle’s braking system.

- Safe Loading and Securing of Cargo: Properly load and secure the cargo in the trailer to prevent shifting, imbalance, or load loss during towing. Use appropriate tie-downs, straps, or cargo nets to secure the load and ensure it does not exceed the trailer’s weight capacity.

- Weather and Road Conditions: Consider the impact of weather and road conditions on towing safety. Adjust driving behavior and speed accordingly, especially in adverse weather conditions such as rain, snow, or strong winds. Be cautious on uneven or slippery road surfaces to maintain control and stability.

- Emergency Preparedness: Equip the towing vehicle and trailer with essential safety equipment, including a spare tire, jack, lug wrench, reflective triangles, and a fire extinguisher. Familiarize yourself with emergency procedures and know how to handle potential towing-related emergencies.

Following these safety considerations when using trailer spindles in towing can help ensure a safe and secure towing experience. It is essential to prioritize regular maintenance, adhere to recommended guidelines, and exercise caution while operating a trailer to prevent accidents, minimize risks, and protect both yourself and other road users.

Can you provide examples of trailers or towing applications that commonly use spindles?

Trailer spindles are widely used in various types of trailers and towing applications. Here are some examples:

- Utility Trailers: Utility trailers, which are used for transporting a wide range of goods and equipment, commonly utilize spindles. These trailers can be found in industries such as construction, landscaping, and agriculture.

- Boat Trailers: Spindles are commonly used in boat trailers to secure the wheels and ensure proper alignment and stability during the transportation of boats to and from the water.

- RV Trailers: Recreational vehicles (RVs) often rely on spindles to support the weight of the trailer and provide a connection point for the wheels. Spindles play a crucial role in maintaining stability and ensuring a smooth towing experience for RV owners.

- Horse Trailers: Horse trailers utilize spindles to secure the wheels and provide stability during transportation. The safety and comfort of the horses being transported are dependent on the proper functioning of the spindles.

- Cargo Trailers: Cargo trailers, commonly used for commercial purposes or moving household goods, rely on spindles to support the weight of the trailer and provide a connection point for the wheels.

- Car Trailers: Trailers designed for transporting cars, such as car carriers or car haulers, utilize spindles to secure the wheels and ensure proper alignment during transportation.

- Travel Trailers: Travel trailers, which are towed behind vehicles for recreational purposes, commonly use spindles to support the weight of the trailer and provide stability during travel.

- Flatbed Trailers: Flatbed trailers, used for transporting large or irregularly shaped cargo, often rely on spindles to secure the wheels and ensure stability and load distribution.

- Enclosed Trailers: Enclosed trailers, commonly used for transporting goods or equipment that require protection from the elements, utilize spindles to support the wheels and ensure proper alignment.

These are just a few examples of trailers and towing applications that commonly use spindles. Spindles are a critical component in various types of trailers, ensuring the stability, load distribution, and safety of the towing system.

When selecting spindles for a specific trailer or towing application, it is important to consider factors such as load capacity, compatibility with other trailer components, and manufacturer recommendations to ensure optimal performance and safety.

What is a trailer spindle, and what role does it play in a trailer’s construction?

A trailer spindle is a crucial component in the construction of a trailer. It serves a vital role in supporting and facilitating the movement of the trailer’s wheels. Here’s a detailed explanation of what a trailer spindle is and its significance in a trailer’s construction:

A trailer spindle is a shaft-like component that connects the trailer axle to the wheel hub. It is typically made of high-strength steel and is responsible for supporting the weight of the trailer and facilitating the rotation of the wheels. The spindle is mounted within the wheel hub assembly and allows the wheel to rotate smoothly and securely.

The trailer spindle performs several important functions:

- Wheel Attachment: The spindle provides a secure attachment point for the trailer wheels. It is designed to fit into the wheel hub assembly and is often tapered to ensure a tight and reliable connection. The wheel is typically mounted on the spindle using lug nuts or bolts, which secure it in place.

- Load Bearing: The trailer spindle bears the weight of the trailer and its cargo. It transfers the load from the trailer’s frame and axle to the wheels, distributing the weight evenly across the axle. The spindle must be strong enough to withstand the weight and forces exerted on the wheels during trailer operation.

- Wheel Rotation: The spindle allows the trailer wheels to rotate freely. As the trailer moves, the spindle transfers the rotational force from the axle to the wheel hub, enabling the wheels to spin. This rotation is essential for the trailer’s mobility and maneuverability.

- Lubrication and Heat Dissipation: Some trailer spindles incorporate grease or oil seals and fittings to allow for lubrication. Proper lubrication reduces friction and wear between the spindle and the wheel hub, enhancing the overall performance and lifespan of the trailer’s wheels. Additionally, the spindle’s design facilitates heat dissipation, helping to prevent excessive heat buildup that can lead to component failure.

In summary, a trailer spindle is a vital component in a trailer’s construction. It serves as the connection between the axle and the wheel hub, providing a secure attachment point for the wheels and supporting the weight of the trailer. The spindle enables the wheels to rotate freely, facilitating the trailer’s mobility. It may also incorporate features for lubrication and heat dissipation to ensure proper functioning and longevity of the trailer’s wheels. Overall, the trailer spindle plays a critical role in maintaining the stability, safety, and performance of the trailer during operation.

editor by CX 2024-03-25