Product Description

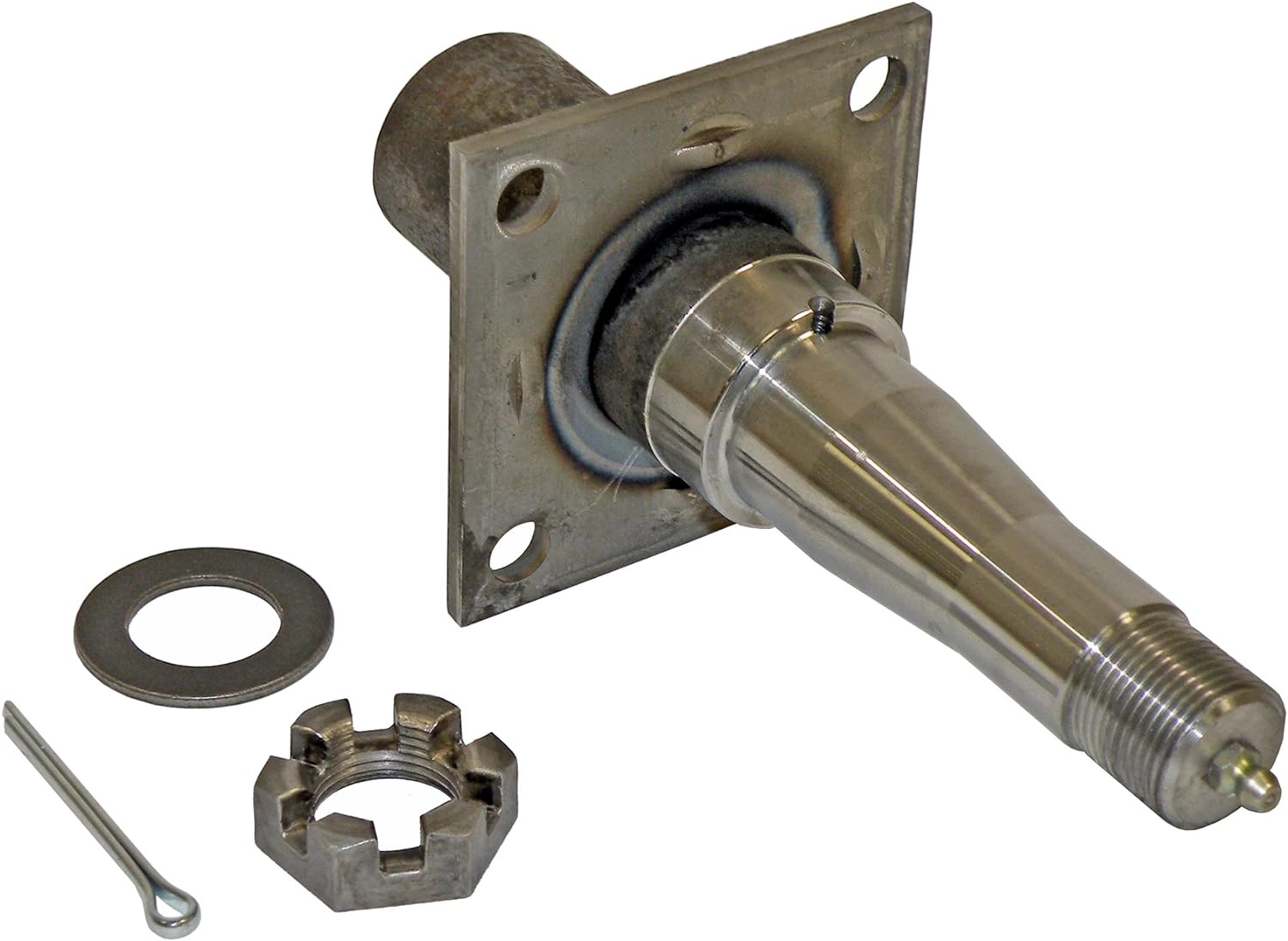

Forging shaft/spindle/roll/roller/axle

Product Disply

Inspection

| Specification | customer’s drawings |

| Material | cast iron, Grey iron, ductile iron, carbon steel, low alloy steel, tool steel, steel, stainless steel, brass, copper, aluminum alloy, zinc etc |

| Process | Sand casting,Coated sand casting,Shell mold casting,Lost foam casting ,V- process,Centrifugal casting,Ceramic Casting,machining,free forging,die forging,pressure forming ,roll forging,precision forging,etc. |

| casting | sand casting,precision casting,centrifugal casting,lost foam casting,die casting,gravity casting |

| machine | lathe,CNC,drilling machine,milling machine,boring machine,planting machine,machining center etc |

| Application | Automobile, agricultural machinery, furniture, construction, home appliances, electronics. |

| surface treatment | powder coating,painting,spraying,electric galvanization,coating,zinc phosphide,impregnation,painting,spray paint,black and blue oxide coating, |

| Inspection equipment | Profile projector,Rockwell hardness tester,Vickers hardness tester roughness tester,air gage,concentricity tester,universial microscope,CMM,digital caliper and etc. |

| Production Usage | Auto parts,train parts,mining accessories,engineering machinery parts,valves,pipe fittings,construction machinery and furniture accessories,agricultural machinery parts |

| Remark | (1)Any RFQ, Please feel free to send your drawings(CAD/PDF)for your quotation. (2)All parts are not in stock, customized only! |

FAQ

Q: What do I need for offering a quote ?

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.) ,quantity, application or samples. Then we will quote the best price within 24h.

Q: What is your MOQ?

A: MOQ depends on our client’s needs, besides,we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to meet customers’ requirement by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A.: T/T, L/C, Escrow, Paypal, western union, etc.

Q: Is it possible to know how is my product going on without visiting your company?

A: We will offer a detailed products schedule and send weekly reports with digital pictures and videos which show the machining progress.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Processing Object: | Metal |

|---|---|

| Molding Style: | Forging |

| Molding Technics: | Gravity Casting |

| Application: | Machinery Parts |

| Material: | Steel |

| Heat Treatment: | Annealing |

| Customization: |

Available

|

|

|---|

Are there innovations or advancements in trailer spindle technology that have emerged recently?

Yes, there have been notable innovations and advancements in trailer spindle technology that have emerged recently. Here’s a detailed explanation:

Trailer spindle technology has continued to evolve to improve the performance, durability, and safety of trailers. Some of the recent innovations and advancements include:

- Sealed Bearing Systems: Sealed bearing systems have become increasingly popular in trailer spindle technology. These systems feature integrated seals that provide enhanced protection against contaminants such as dirt, water, and debris. The sealed design helps to prolong the life of the bearings by reducing the risk of premature wear and damage. It also minimizes maintenance requirements by eliminating the need for regular bearing re-greasing.

- Improved Bearing Materials: Recent advancements have led to the development of advanced bearing materials for trailer spindles. Materials such as ceramic and advanced polymers offer superior strength, corrosion resistance, and durability compared to traditional steel bearings. These advanced bearing materials contribute to extended bearing life, reduced friction, and improved overall performance of the trailer spindles.

- High-Strength Spindle Construction: Manufacturers have been focusing on improving the strength and durability of trailer spindles. This includes the use of high-strength materials such as forged steel or alloy steel in the construction of spindles. These materials provide increased load capacity, enhanced resistance to bending or deformation, and improved structural integrity, ensuring reliable and safe towing operations.

- Intelligent Monitoring Systems: Some advancements in trailer spindle technology have introduced intelligent monitoring systems. These systems utilize sensors and advanced electronics to monitor spindle performance in real-time. They can detect abnormalities such as excessive heat, vibration, or bearing wear and provide early warning alerts to the operator. Intelligent monitoring systems help prevent potential failures, reduce downtime, and enhance overall safety during towing.

- Enhanced Corrosion Resistance: With a focus on improving the longevity of trailer spindles, advancements have been made in enhancing corrosion resistance. This includes the use of specialized coatings, surface treatments, or materials that provide superior protection against corrosion caused by factors like moisture, salt, or harsh environmental conditions. Enhanced corrosion resistance helps to prolong the lifespan of the spindles and ensures their optimal functionality over an extended period.

These recent innovations and advancements in trailer spindle technology have contributed to improved performance, increased durability, and enhanced safety in towing systems. They address common challenges such as bearing maintenance, corrosion, load capacity, and monitoring, providing trailer owners with more reliable and efficient options for their towing needs.

It’s important to note that the availability and implementation of these advancements may vary among different manufacturers and models of trailers. When considering the latest innovations in trailer spindle technology, it’s advisable to consult with manufacturers, industry experts, or trusted suppliers to explore the specific features and benefits offered by different spindle systems.

How do trailer spindles impact the performance and safety of a towing system?

Trailer spindles play a crucial role in influencing the performance and safety of a towing system. Here’s a detailed explanation of how trailer spindles impact towing system performance and safety:

- Wheel Attachment and Stability:

Trailer spindles provide the attachment point for the trailer wheels. They secure the wheels to the trailer and ensure proper alignment and stability during towing. A well-designed and properly installed spindle contributes to the overall stability of the trailer, minimizing the risk of wheel detachment, wobbling, or excessive vibrations. This enhances the towing system’s performance and improves safety on the road.

- Load Distribution:

Trailer spindles play a crucial role in distributing the weight of the load across the trailer axle. As the load is transferred from the trailer frame to the wheels through the spindles, they help maintain proper load distribution. Balanced load distribution is vital for safe towing, as it minimizes the risk of overloading certain wheels or axles, which could lead to instability and compromised handling.

- Strength and Durability:

The strength and durability of trailer spindles directly impact the towing system’s performance and safety. Spindles should be designed and manufactured to withstand the weight and forces exerted on the trailer during towing. High-quality spindles made from robust materials, such as steel, provide the necessary strength and durability to handle the load and maintain stability. Weak or compromised spindles can lead to failures, resulting in accidents or damage to the trailer and other vehicles.

- Wheel Alignment and Tracking:

Proper wheel alignment and tracking are critical for the safe operation of a towing system. Trailer spindles play a role in maintaining the correct alignment of the wheels. Misaligned wheels can cause uneven tire wear, reduced fuel efficiency, and compromised stability during towing. Well-designed spindles ensure that the wheels are aligned correctly, promoting smooth and predictable towing performance.

- Smooth and Controlled Towing:

Trailer spindles contribute to achieving smooth and controlled towing experiences. They facilitate smooth wheel rotation, allowing the wheels to spin freely and reduce friction. Smooth rotation enhances the overall performance of the towing system, promoting better fuel efficiency, reduced wear on trailer components, and improved handling and control.

- Compatibility with Suspension System:

Trailer spindles need to work in conjunction with the trailer’s suspension system. The spindle design and specifications should be compatible with the suspension components, such as leaf springs or torsion axles. Proper compatibility ensures that the spindles can handle the movement and forces generated by the suspension system, maintaining stability and minimizing the impact of uneven or rough road surfaces.

- Compliance with Safety Standards:

Trailer spindles must meet safety standards and regulations to ensure the overall safety of the towing system. Compliance with these standards ensures that the spindles are designed, manufactured, and installed to provide the necessary strength, stability, and reliability for safe towing operations.

In summary, trailer spindles have a significant impact on the performance and safety of a towing system. They contribute to wheel attachment and stability, facilitate load distribution, provide strength and durability, influence wheel alignment and tracking, enable smooth and controlled towing, ensure compatibility with the suspension system, and comply with safety standards. Choosing high-quality spindles and ensuring proper installation and maintenance are essential for a safe and reliable towing experience.

What is a trailer spindle, and what role does it play in a trailer’s construction?

A trailer spindle is a crucial component in the construction of a trailer. It serves a vital role in supporting and facilitating the movement of the trailer’s wheels. Here’s a detailed explanation of what a trailer spindle is and its significance in a trailer’s construction:

A trailer spindle is a shaft-like component that connects the trailer axle to the wheel hub. It is typically made of high-strength steel and is responsible for supporting the weight of the trailer and facilitating the rotation of the wheels. The spindle is mounted within the wheel hub assembly and allows the wheel to rotate smoothly and securely.

The trailer spindle performs several important functions:

- Wheel Attachment: The spindle provides a secure attachment point for the trailer wheels. It is designed to fit into the wheel hub assembly and is often tapered to ensure a tight and reliable connection. The wheel is typically mounted on the spindle using lug nuts or bolts, which secure it in place.

- Load Bearing: The trailer spindle bears the weight of the trailer and its cargo. It transfers the load from the trailer’s frame and axle to the wheels, distributing the weight evenly across the axle. The spindle must be strong enough to withstand the weight and forces exerted on the wheels during trailer operation.

- Wheel Rotation: The spindle allows the trailer wheels to rotate freely. As the trailer moves, the spindle transfers the rotational force from the axle to the wheel hub, enabling the wheels to spin. This rotation is essential for the trailer’s mobility and maneuverability.

- Lubrication and Heat Dissipation: Some trailer spindles incorporate grease or oil seals and fittings to allow for lubrication. Proper lubrication reduces friction and wear between the spindle and the wheel hub, enhancing the overall performance and lifespan of the trailer’s wheels. Additionally, the spindle’s design facilitates heat dissipation, helping to prevent excessive heat buildup that can lead to component failure.

In summary, a trailer spindle is a vital component in a trailer’s construction. It serves as the connection between the axle and the wheel hub, providing a secure attachment point for the wheels and supporting the weight of the trailer. The spindle enables the wheels to rotate freely, facilitating the trailer’s mobility. It may also incorporate features for lubrication and heat dissipation to ensure proper functioning and longevity of the trailer’s wheels. Overall, the trailer spindle plays a critical role in maintaining the stability, safety, and performance of the trailer during operation.

editor by CX 2024-01-16