Product Description

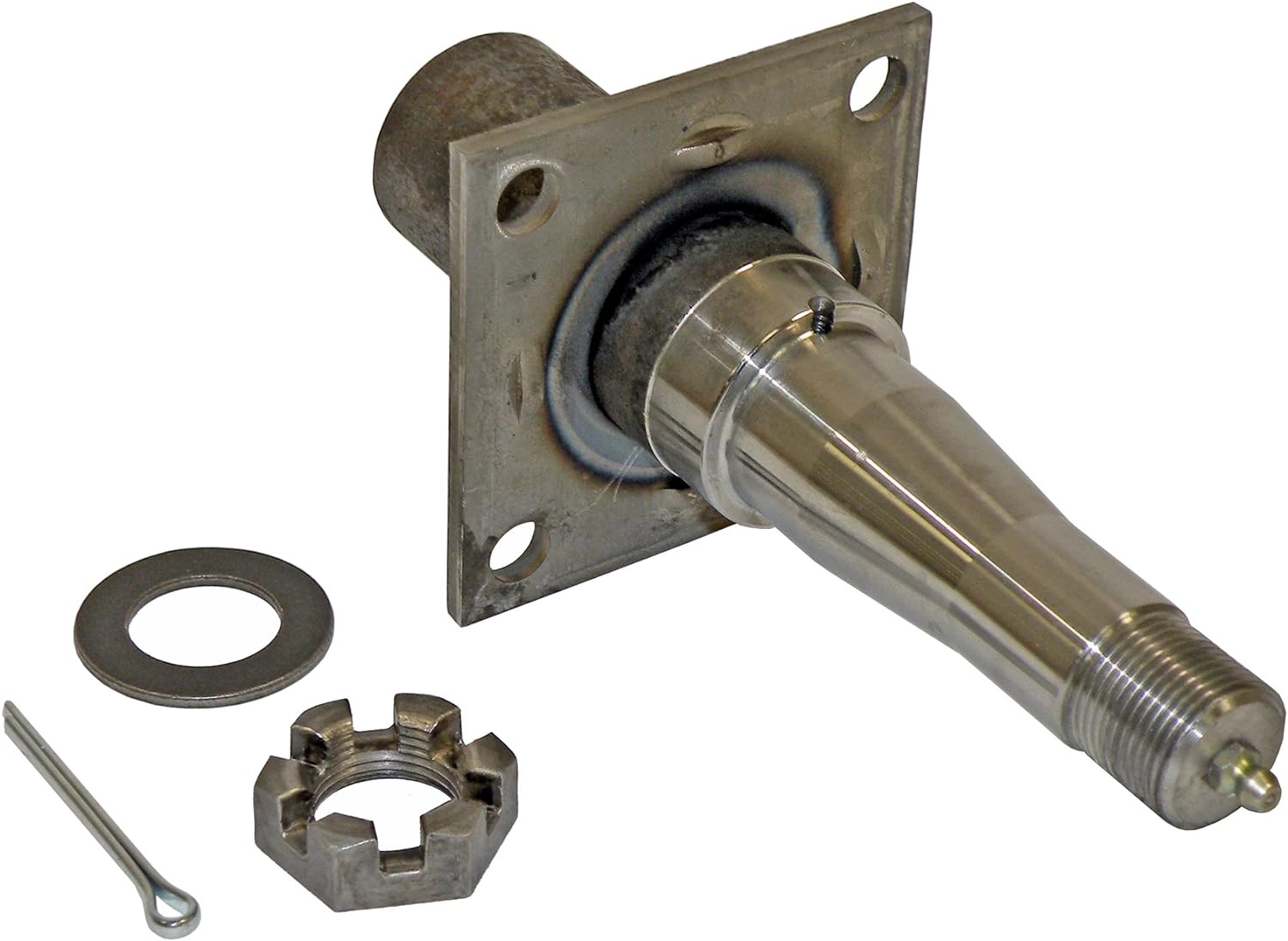

5 Bolts Round Square Spindle Boat Trailer Half Stub Axle Hub and Spindle Assembly

|

item |

value |

|

Place of CHINAMFG |

China |

|

Province |

ZheJiang |

|

Model Number |

Customized Services |

|

Process |

Mainly Hot forging, Some parts with Cold forging ,die forging and Free forgin will be OK |

|

Material |

Carbon steel: CM490,A36,1045,1035 etc., Alloy steel: 40Cr, 20CrMnTi, 20CrNiMo, 42CrMo4 etc., Stainless steel, SS304,SS316 etc. |

|

Weight |

1kg – 120kg |

|

Applicable Machining Process |

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc. |

|

Machining Tolerance |

0.03mm-0.1mm |

|

Applicable Finish Surface Treatment |

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting, |

|

Testing equipment |

Supersonic inspection machine, Supersonic flaw detecting machine , physics and chemical analysis. |

|

MOQ of mass production |

1000-5000pcs |

|

Testing equipment |

Optical Spectrum Analyzer,tensile testing machine,impact testing machine,fluorescent magnetic particle detector,hardness tester,ultrasonic flaw detector..etc. |

|

Packing |

Wooden cases or according to customers’ needs |

1. who are we?

We are based in ZheJiang , China, start from 2571,sell to North America(10.00%),South America(10.00%),Southeast

Asia(10.00%),Africa(10.00%),Mid East(10.00%),Eastern Asia(10.00%),Central America(10.00%),Northern Europe(10.00%),South

Asia(10.00%),Domestic Market(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

semi trailer axles, air suspensions , chamber,wheel ,slack adjuster and other related items.

4. why should you buy from us not from other suppliers?

We have a trailer parts production more than 10 years the supply chain

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese

6.what is the certificate

At present, the company can undertake CCS, ABS, BV, GL and other certification products /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Available |

|---|---|

| Condition: | New |

| Application: | Trailer |

| Certification: | ASTM, CE, DIN, ISO |

| Material: | Steel |

| Transport Package: | Customized |

| Customization: |

Available

|

|

|---|

What safety considerations should be taken into account when using trailer spindles in towing?

When using trailer spindles in towing, several safety considerations should be taken into account. Here’s a detailed explanation:

- Proper Installation: Ensure that the trailer spindles are installed correctly according to the manufacturer’s guidelines. This includes securely attaching the spindles to the trailer frame and using appropriate hardware and torque specifications. Improper installation can compromise the structural integrity of the trailer and lead to handling issues or failure during towing.

- Regular Inspection and Maintenance: Regularly inspect the trailer spindles for signs of wear, damage, or misalignment. Check for any cracks, corrosion, or loose components. Additionally, inspect the bearings, seals, and lubrication system to ensure they are in good condition. Perform routine maintenance tasks such as greasing the bearings and replacing worn-out parts as recommended by the manufacturer.

- Proper Weight Distribution: Ensure that the trailer’s load is properly distributed to avoid overloading the spindles or placing excessive stress on specific components. Follow the manufacturer’s guidelines for the trailer’s maximum load capacity and distribute the weight evenly across the axles. Improper weight distribution can lead to instability, reduced braking performance, and increased risk of accidents.

- Appropriate Speed and Driving Behavior: Adhere to safe driving practices when towing a trailer. Maintain a safe and appropriate speed, considering the load, road conditions, and legal limits. Avoid sudden maneuvers, excessive braking, and rapid acceleration, as they can exert additional stress on the spindles and other towing components.

- Tire Maintenance: Properly maintained tires are essential for safe towing. Ensure that the trailer tires are properly inflated, have adequate tread depth, and are in good overall condition. Uneven tire wear or worn-out tires can affect the stability and handling of the trailer, potentially leading to accidents or tire blowouts.

- Proper Hitching and Coupling: Ensure that the trailer is properly hitched and coupled to the towing vehicle. Use a hitch that matches the trailer’s weight capacity, and ensure that the coupling mechanism is engaged securely. Improper hitching or coupling can result in trailer detachment, loss of control, or accidents.

- Trailer Braking System: If the trailer is equipped with brakes, ensure that the braking system is properly maintained and functioning correctly. Regularly inspect and test the brakes to ensure they provide adequate stopping power and are synchronized with the towing vehicle’s braking system.

- Safe Loading and Securing of Cargo: Properly load and secure the cargo in the trailer to prevent shifting, imbalance, or load loss during towing. Use appropriate tie-downs, straps, or cargo nets to secure the load and ensure it does not exceed the trailer’s weight capacity.

- Weather and Road Conditions: Consider the impact of weather and road conditions on towing safety. Adjust driving behavior and speed accordingly, especially in adverse weather conditions such as rain, snow, or strong winds. Be cautious on uneven or slippery road surfaces to maintain control and stability.

- Emergency Preparedness: Equip the towing vehicle and trailer with essential safety equipment, including a spare tire, jack, lug wrench, reflective triangles, and a fire extinguisher. Familiarize yourself with emergency procedures and know how to handle potential towing-related emergencies.

Following these safety considerations when using trailer spindles in towing can help ensure a safe and secure towing experience. It is essential to prioritize regular maintenance, adhere to recommended guidelines, and exercise caution while operating a trailer to prevent accidents, minimize risks, and protect both yourself and other road users.

How does the choice of materials impact the durability and reliability of trailer spindles?

The choice of materials for trailer spindles has a significant impact on their durability and reliability. Here’s a detailed explanation:

The materials used in the construction of trailer spindles play a crucial role in determining their strength, corrosion resistance, and overall performance. Different materials offer varying levels of durability and reliability in different operating conditions and environments.

- Steel:

Steel is a commonly used material for trailer spindles due to its excellent strength and durability. Steel spindles are known for their ability to withstand heavy loads and provide reliable performance. They are often preferred for applications that require high load capacities, such as commercial trailers or trailers used in demanding industries. Steel spindles can handle rough terrains, frequent use, and challenging towing conditions.

- Aluminum:

Aluminum spindles offer several advantages, including lightweight construction and corrosion resistance. They are commonly used in applications where weight reduction is important, such as recreational trailers or trailers that require improved fuel efficiency. Aluminum spindles provide good durability and reliability while reducing the overall weight of the trailer, which can result in improved towing performance.

- Ductile Iron:

Ductile iron spindles offer a combination of strength, durability, and cost-effectiveness. They are known for their ability to withstand heavy loads and provide reliable performance in various towing applications. Ductile iron spindles are often chosen for their high strength-to-weight ratio and resistance to wear and deformation.

- Composite Materials:

Composite materials, such as fiberglass-reinforced polymers, are gaining popularity in the manufacturing of trailer spindles. These materials offer advantages such as high strength-to-weight ratio, corrosion resistance, and reduced maintenance requirements. Composite spindles can provide excellent durability and reliability while being lighter in weight compared to traditional materials like steel or iron.

When selecting the material for trailer spindles, it’s important to consider the specific requirements of the towing application. Factors such as load capacity, operating conditions, and environmental factors should be taken into account. Additionally, it’s crucial to follow the manufacturer’s recommendations regarding material selection to ensure compatibility with other trailer components and adherence to safety standards.

In summary, the choice of materials significantly impacts the durability and reliability of trailer spindles. Steel spindles offer excellent strength and durability, while aluminum spindles provide lightweight construction and corrosion resistance. Ductile iron spindles offer a combination of strength and cost-effectiveness. Composite materials offer a lightweight alternative with high strength-to-weight ratios. By selecting the appropriate material based on the specific towing requirements, trailer owners can ensure the longevity, performance, and reliability of their trailer spindles.

Can you explain the primary functions and importance of trailer spindles in towing?

Trailer spindles play crucial functions and hold significant importance in towing operations. Here’s a detailed explanation of the primary functions and importance of trailer spindles in towing:

- Wheel Attachment:

The primary function of a trailer spindle in towing is to provide a secure attachment point for the trailer wheels. The spindle is designed to fit into the wheel hub assembly and allows for the installation of the wheels. It typically utilizes lug nuts or bolts to secure the wheel tightly to the spindle, ensuring that it remains in place during towing.

- Load Bearing:

Trailer spindles bear the weight of the trailer and its cargo. As the trailer moves, the weight is transferred from the trailer’s frame and axle to the wheels through the spindles. The spindles distribute the load evenly across the axle, ensuring that the weight is adequately supported. It is crucial for the spindles to be strong enough to handle the weight and forces exerted on the wheels during towing.

- Wheel Rotation:

Another essential function of trailer spindles is to facilitate the rotation of the wheels. As the towing vehicle moves forward, the spindles transfer the rotational force from the trailer axle to the wheel hubs, allowing the wheels to rotate freely. This rotation enables the trailer to move smoothly and maneuver effectively.

- Lubrication and Heat Dissipation:

Trailer spindles may incorporate features for lubrication and heat dissipation. Proper lubrication is essential to reduce friction and wear between the spindle and the wheel hub, ensuring smooth wheel rotation and minimizing the risk of damage. Some spindles include grease or oil seals and fittings that allow for regular lubrication. Additionally, the spindle’s design often includes mechanisms to dissipate heat generated during towing. Effective heat dissipation helps prevent excessive heat buildup, which can lead to component failure.

- Maintaining Stability and Control:

The proper functioning of trailer spindles is crucial for maintaining stability and control during towing. The secure attachment of the wheels to the spindles ensures that they remain in place, preventing wheel separation or instability. The even distribution of weight across the spindles promotes balanced towing, minimizing the risk of swaying or fishtailing. The smooth rotation of the wheels facilitated by the spindles enables precise maneuvering and control of the trailer.

- Overall Safety:

The importance of trailer spindles in towing cannot be overstated in terms of safety. Reliable and properly functioning spindles contribute to the overall safety of the towing operation. By securely attaching the wheels and maintaining stability, they help prevent accidents or incidents caused by wheel detachment, loss of control, or trailer instability. Proper lubrication and heat dissipation also minimize the risk of mechanical failures or damage that could compromise safety.

In summary, trailer spindles serve primary functions and hold significant importance in towing. They provide a secure attachment point for the wheels, bear the weight of the trailer and cargo, facilitate wheel rotation, allow for lubrication and heat dissipation, maintain stability and control, and contribute to overall towing safety. Choosing high-quality spindles and ensuring their proper maintenance and functionality are crucial for safe and efficient towing operations.

editor by Dream 2024-04-19