Product Description

Products Description

Like other cast steel alloys, stainless steel is a common material for casting production. When the properties of steel and corrosion resistance are required for products, Stainless steel casting is the best choice.

Stainless steel casting, also called stainless steel investment casting, refers to the formation of ceramics around a wax pattern to form a shell for casting stainless steel. Once wax patterns are created, they are melted into the gate system, immersed in slurry and sand to form a layered shell, and then replaced by molten stainless steel.

How are Stainless Steel Castings Made?

Stainless steel casting involves creating an original wax model, building the image with plaster and successive layers until a strong shell surrounds the model. After melting the wax, pour the molten stainless steel into the mold to create a perfect replica of the original wax pattern. Stainless steel casting provides economical undercutting, high resolution, sophisticated detail, and a smooth surface finish compared to machining separations.

In most cases, stainless steel casting is the only way the part can be made economically.

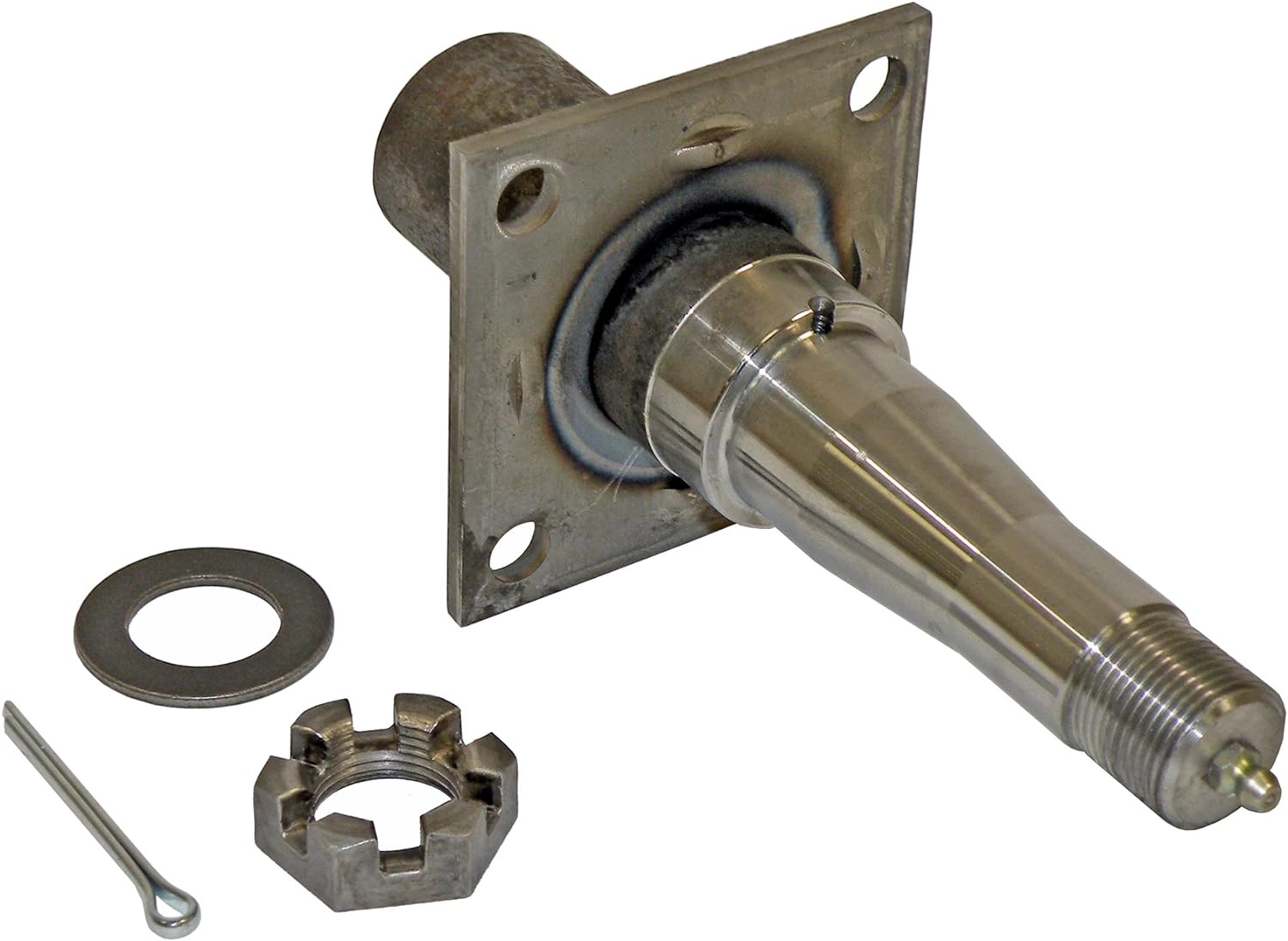

Stainless steel casting trailer axle spindle

Common Material Grades of Stainless Steel Casting

- 304-The most widely used austenite steel, may be referred to as A2 stainless.

- 304L-This grade has slightly lower mechanical properties than the standard 304 grade, but is still widely used in casting for its versatility.

- 316--The second most common austenite steel, also referred to as A4 stainless. SS316 is used primarily for its increased resistance to corrosion.

- 316L-Lower carbon content than 316 stainless steel, which reduces the sensitization effect caused by the high temperatures involved in welding. Besides, it shows better resistance to stress-corrosion cracking.

- 17-4 PH -Most common precipitation-hardening martensitic stainless steel, which uses about 17% chromium and 4% nickel.

- 2205 Duplex-Used for its good mechanical properties and excellent corrosion resistance properties.

Common Cast Stainless Steel Grades,Features, Applications

| Grades | Features | Applications |

| 304 | Austenitic stainless steel with Ni content more than 8%, food-grade alloy. can be used to cast stainless steel components for both household and commercial applications. Widely used stainless steel casting material. 304 stainless steel castings can be used in environments where the air is less corrosive. |

Medical, food industry, chemical industry, mechanical equipment, pipe industry, automotive industry, etc. |

| 316 | Also austenitic stainless steel with Ni content of more than 10%. For their higher Ni content, 316 stainless steel castings have better corrosion resistance than 304 stainless steel castings. Such stainless steel castings better suit the marine environment with relatively harsh air conditions or chemical materials that need to be contacted. | Fire fighting, auto parts, marine hardwares, chemical, pipeline, construction, decoration, food industry, etc. |

| 304L / 316L | The mechanical properties are close to those of 304 and 316 materials. L represents lower carbon content, which makes the material more ductile, has good welding performance, and has more reliable corrosion resistance. The price is higher than that of materials of the same grade. | Food, chemical, medical, plumbing, etc. |

| 410 & 416 | Series 400 belongs to martensitic stainless steel, which is characterized by high strength, good processing performance, and high heat treatment hardness, and does not contain Ni, so the corrosion resistance is weak. | Auto parts, tools, knives, etc. |

| 17-4 PH | 17-4 belongs to martensitic stainless steel with a Ni content of 3%-5% and good corrosion resistance. It has the highest strength in the stainless steel series and is usually used for products and components that are not prone to deformation. | Medical, mechanical components, machine tools, turbine blades, etc. |

| 2205 | Duplex stainless steel 2205 is composite stainless steel consisting of 22% chromium, 2.5% molybdenum, and 4.5% nickel-nitrogen. It has high strength, good impact toughness, and good overall and local resistance to stress corrosion. | Sporting, pump & valve industry, etc. |

Stainless Steel Castings Application

Stainless steel has unique physical properties. Such as extremely high resistance to heat, abrasion, and corrosion. So it can be served for a different range of industries, especially in some severe environments. Here are the main usages of stainless steel casting:

1-Food processing and machinery:

A large amount of stainless steel is also used in food production and storage. Almost all food processing equipment is made of stainless steel. The most common grades are 304 and 316. 304 is basically the main level, while 316 is used in the harsher environment. Stainless steel castings are widely used in food machinery applications due to their rust-preventing capabilities and the most flexible manufacturing processes for complex-shaped parts. Typical food machinery parts made with stainless steel casting processes are metal grinder parts, coffee machine parts, etc. An important reason for using stainless steel is not the corrosive nature of the food itself, but the use of stainless steel for faster and more efficient cleaning. The advantage is that it does not expose the food to any taste.

2-Kitchenware and Cutlery in kitchen

The most commonly used stainless steel may be used for tableware and Cutlery in the kitchen. For example, Grade 410 and 420 can be hardened and tempered, allowing the blade to use sharp edges to produce tools. Grade 304 (18/8 stainless steel, 18% chromium 8% nickel), more ductile 18/8 stainless steel is easier to a machine. So it is more suitable for objects that need many molding, polishing, and grinding processes for spoons and forks, and other tableware.

3-Marine:

Stainless steel casting is used in marine applications which require parts that are strong with extremely high resistance to heat, abrasion, and corrosion. Our stainless steel alloys for recreational, commercial marine components. Stainless steel marine castings can be polished to a mirror finish for maximum corrosion and abrasion resistance. New marine grade stainless steel investment castings for marine application could be supplied electronically polished and machined from our company, saving our customers 40% on their current cost.

4-Medical Equipment:

Stainless steel casting can produce a wide range of components and medical implants for medical instrument manufacturers. We work with many stainless steel materials, including stainless steel 304(L), stainless steel 316(L), and more, to create custom parts that meet the tight tolerances and dimensional precision required by the medical application.

A great deal of medical equipment – such as orthopedic beds, cabinets, and examination machines – is made as standard from stainless because of its hygienic and easy-clean qualities. What we can offer more Stainless steel cast parts included in surgical tools, Implantable components, operating tables & other operating room equipment, stretchers, wheelchairs, and similar products, stabilizing devices.

5-Pipe Fittings:

Stainless steel pipe fittings come in a variety of shapes, so the installation process is convenient. Because of the high performance and durability of stainless steel fittings, stainless steel fittings are widely used for piping construction and installation. Stainless steel pipe fittings are available in stainless steel flanges, stainless steel heads,elbow, tee, bushing, close nipples, etc. Our machining capability can meet any machining requirement like threads. When purchasing pipe fittings, considering the application, these pipe fittings are normally made of stainless steel 316, which is higher strength and more corrosion resistant than stainless steel 304.

6-Pump and Components:

Stainless steel casting is 1 of the most widely used techniques for valve and pump components. Common valve and pump components made from stainless steel casting include valve body, valve disc, valve bonnet, valve gland, pump body, pump impeller, etc. Since its complicated design of valve and pump components, stainless steel casting can produce any complex shape. Valve and pump components from stainless steel casting are durable enough for severe service applications. So stainless steel casting is a cost-efficient way and a popular selection for pump and valve applications.

7-Building and Construction

Modern buildings use more stainless steel for cladding, roofing, and facades. It has low maintenance cost and anti-vandal characteristics and aesthetics. Especially the public construction market. Stainless steel reinforcing bar, although initially expensive, is proving to have very good life cycle costing characteristics.

Other usages of Stainless Steel Castings are Door & Windows, Bathroom & Toilet fittings, etc.

Quality Control

1) Checking the raw material after they reach our factory——- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have a full inspection and routing inspection during mass production—In-process quality control(IPQC)

4) Checking the goods after they are finished—- Final quality control(FQC)

5) Checking the goods after they are finished—–Outgoing quality control(OQC)

FAQ

Q: Are you a trading company or manufacturer?

A: We are a factory with more than 20 years’ experience.

Q: How long for delivery?

A: Generally it is 15-30days as we are a customized service we confirm with customers when place order.

Q: What is the MOQ?

A: It depends on what you are buying. Normally, our minimum order is 1 20′ full container and an LCL container (less than a

container load) can be acceptable.

Q: Can you customize my products?

A: Yes, we can customize products with your design drawings like DWG, DXF, DXW, IGES, STEP, PDF, etc.

Q: What is your terms of payment?

A: 30% T/T in advance, balance before shipment, or as per discussion.

Q: What about your quality control?

A: * . Checking the raw material after they reach our factory—–Incoming quality control(IQC)

* . Checking the details before the production line operated

* . Have a full inspection and routing inspection during mass production—-In-process quality control(IPQC)

* . Checking the goods after they are finished—-Final quality control(FQC)

* . Checking the goods after they are finished—-Outgoing quality control(QC)

* . 100% inspection and delivery before shipment /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Video Technical Support, Online Support, Engineers |

|---|---|

| Warranty: | 1 Year |

| Condition: | New |

| Certification: | CE, RoHS, GS, ISO9001 |

| Standard: | DIN, ASTM, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Customization: |

Available

|

|

|---|

Are there innovations or advancements in trailer spindle technology that have emerged recently?

Yes, there have been notable innovations and advancements in trailer spindle technology that have emerged recently. Here’s a detailed explanation:

Trailer spindle technology has continued to evolve to improve the performance, durability, and safety of trailers. Some of the recent innovations and advancements include:

- Sealed Bearing Systems: Sealed bearing systems have become increasingly popular in trailer spindle technology. These systems feature integrated seals that provide enhanced protection against contaminants such as dirt, water, and debris. The sealed design helps to prolong the life of the bearings by reducing the risk of premature wear and damage. It also minimizes maintenance requirements by eliminating the need for regular bearing re-greasing.

- Improved Bearing Materials: Recent advancements have led to the development of advanced bearing materials for trailer spindles. Materials such as ceramic and advanced polymers offer superior strength, corrosion resistance, and durability compared to traditional steel bearings. These advanced bearing materials contribute to extended bearing life, reduced friction, and improved overall performance of the trailer spindles.

- High-Strength Spindle Construction: Manufacturers have been focusing on improving the strength and durability of trailer spindles. This includes the use of high-strength materials such as forged steel or alloy steel in the construction of spindles. These materials provide increased load capacity, enhanced resistance to bending or deformation, and improved structural integrity, ensuring reliable and safe towing operations.

- Intelligent Monitoring Systems: Some advancements in trailer spindle technology have introduced intelligent monitoring systems. These systems utilize sensors and advanced electronics to monitor spindle performance in real-time. They can detect abnormalities such as excessive heat, vibration, or bearing wear and provide early warning alerts to the operator. Intelligent monitoring systems help prevent potential failures, reduce downtime, and enhance overall safety during towing.

- Enhanced Corrosion Resistance: With a focus on improving the longevity of trailer spindles, advancements have been made in enhancing corrosion resistance. This includes the use of specialized coatings, surface treatments, or materials that provide superior protection against corrosion caused by factors like moisture, salt, or harsh environmental conditions. Enhanced corrosion resistance helps to prolong the lifespan of the spindles and ensures their optimal functionality over an extended period.

These recent innovations and advancements in trailer spindle technology have contributed to improved performance, increased durability, and enhanced safety in towing systems. They address common challenges such as bearing maintenance, corrosion, load capacity, and monitoring, providing trailer owners with more reliable and efficient options for their towing needs.

It’s important to note that the availability and implementation of these advancements may vary among different manufacturers and models of trailers. When considering the latest innovations in trailer spindle technology, it’s advisable to consult with manufacturers, industry experts, or trusted suppliers to explore the specific features and benefits offered by different spindle systems.

What maintenance practices are recommended for trailer spindles to ensure optimal functionality?

Proper maintenance of trailer spindles is essential to ensure their optimal functionality and extend their lifespan. Here are some recommended maintenance practices:

- Regular Inspections: Conduct regular visual inspections of the trailer spindles to check for any signs of damage, wear, or corrosion. Look for cracks, bends, or excessive rust that may compromise the spindle’s integrity. Inspect the spindle nuts, bearings, and seals for proper alignment and condition.

- Lubrication: Proper lubrication is crucial for smooth spindle operation and minimizing friction. Follow the manufacturer’s recommendations for lubrication intervals and use a high-quality grease suitable for trailer spindles. Apply grease to the bearings and spindle surfaces as per the instructions, ensuring even distribution.

- Bearing Maintenance: Inspect and repack the wheel bearings regularly to prevent overheating and premature wear. Clean the bearings and races thoroughly, remove old grease, and repack them with fresh grease. Replace worn or damaged bearings promptly to avoid potential failures.

- Seal Inspection: Check the condition of the spindle seals to ensure they provide adequate protection against dirt, water, and contaminants. Replace damaged or worn seals to maintain proper lubrication and prevent moisture ingress, which can lead to bearing damage.

- Torque Checks: Periodically check and adjust the torque of the spindle nuts to ensure proper bearing adjustment. Follow the manufacturer’s specifications for the recommended torque values and tightening sequence. Over-tightened or loose spindle nuts can lead to bearing damage and compromised spindle performance.

- Brake System Maintenance: If the trailer has brake spindles, inspect and maintain the brake system components as per the manufacturer’s recommendations. Check the brake pads, calipers, and brake lines for wear, damage, or leaks. Keep the braking system clean and adjust the brakes as necessary for optimal stopping performance.

- Protection from Environmental Elements: Protect the spindles from harsh environmental conditions, such as excessive moisture, saltwater, or chemicals. If the trailer is exposed to these elements, consider using protective coatings or covers to minimize corrosion and damage.

- Professional Servicing: For complex maintenance tasks or if you’re unsure about any specific maintenance procedure, it’s recommended to seek professional servicing. Trained technicians can perform comprehensive inspections, bearing replacements, or other specialized maintenance tasks to ensure the optimal functionality of the trailer spindles.

Following these maintenance practices will help ensure the optimal functionality and longevity of trailer spindles. Regular inspections, proper lubrication, bearing maintenance, seal inspections, torque checks, brake system maintenance, protection from environmental elements, and professional servicing when needed are all important steps in maintaining trailer spindles in good working condition.

Remember to consult the trailer manufacturer’s guidelines and recommendations for specific maintenance requirements and intervals based on the spindle type and trailer model.

What is a trailer spindle, and what role does it play in a trailer’s construction?

A trailer spindle is a crucial component in the construction of a trailer. It serves a vital role in supporting and facilitating the movement of the trailer’s wheels. Here’s a detailed explanation of what a trailer spindle is and its significance in a trailer’s construction:

A trailer spindle is a shaft-like component that connects the trailer axle to the wheel hub. It is typically made of high-strength steel and is responsible for supporting the weight of the trailer and facilitating the rotation of the wheels. The spindle is mounted within the wheel hub assembly and allows the wheel to rotate smoothly and securely.

The trailer spindle performs several important functions:

- Wheel Attachment: The spindle provides a secure attachment point for the trailer wheels. It is designed to fit into the wheel hub assembly and is often tapered to ensure a tight and reliable connection. The wheel is typically mounted on the spindle using lug nuts or bolts, which secure it in place.

- Load Bearing: The trailer spindle bears the weight of the trailer and its cargo. It transfers the load from the trailer’s frame and axle to the wheels, distributing the weight evenly across the axle. The spindle must be strong enough to withstand the weight and forces exerted on the wheels during trailer operation.

- Wheel Rotation: The spindle allows the trailer wheels to rotate freely. As the trailer moves, the spindle transfers the rotational force from the axle to the wheel hub, enabling the wheels to spin. This rotation is essential for the trailer’s mobility and maneuverability.

- Lubrication and Heat Dissipation: Some trailer spindles incorporate grease or oil seals and fittings to allow for lubrication. Proper lubrication reduces friction and wear between the spindle and the wheel hub, enhancing the overall performance and lifespan of the trailer’s wheels. Additionally, the spindle’s design facilitates heat dissipation, helping to prevent excessive heat buildup that can lead to component failure.

In summary, a trailer spindle is a vital component in a trailer’s construction. It serves as the connection between the axle and the wheel hub, providing a secure attachment point for the wheels and supporting the weight of the trailer. The spindle enables the wheels to rotate freely, facilitating the trailer’s mobility. It may also incorporate features for lubrication and heat dissipation to ensure proper functioning and longevity of the trailer’s wheels. Overall, the trailer spindle plays a critical role in maintaining the stability, safety, and performance of the trailer during operation.

editor by CX 2024-01-11