Product Description

Product parameters and prices for reference only, the actual situation of the product please consult or call!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Availiable |

|---|---|

| Condition: | New |

| Axle Number: | 2 |

| Application: | Trailer |

| Certification: | ISO |

| Material: | Steel |

| Customization: |

Available

|

|

|---|

What are the signs that indicate a need for trailer spindle replacement or maintenance, and how can they be diagnosed?

Proper maintenance and timely replacement of trailer spindles are essential for safe towing. Here’s a detailed explanation of the signs that indicate a need for spindle replacement or maintenance and how they can be diagnosed:

- 1. Excessive Play or Movement: If you notice excessive play or movement in the trailer wheels when jacked up or during towing, it may indicate worn-out or damaged spindles. To diagnose this, you can grasp the tire at the top and bottom and try to wiggle it. Excessive movement or play indicates a potential issue with the spindles that requires inspection and possible replacement.

- 2. Abnormal Noises: Unusual noises, such as grinding, squeaking, or rumbling sounds, coming from the trailer wheels while in motion can be a sign of spindle problems. These noises may indicate worn-out bearings, insufficient lubrication, or misaligned spindles. To diagnose the issue, you can listen for any unusual noises while towing or rotating the trailer wheels by hand. If abnormal sounds are present, it is recommended to inspect the spindles and bearings for damage or wear.

- 3. Irregular Tire Wear: Pay attention to the tire wear patterns on the trailer. If you notice uneven or abnormal tire wear, such as cupping, feathering, or bald spots, it could be an indication of misaligned or damaged spindles. To diagnose this, visually inspect the tires for any signs of uneven wear and check for any underlying issues with the spindles or suspension system.

- 4. Excessive Heat: Overheating of the trailer spindles can be a sign of bearing or lubrication problems. If you feel excessive heat when touching the spindle after a tow, it may indicate inadequate lubrication, worn-out bearings, or other issues. To diagnose this, carefully touch the spindles after towing and check for any unusual heat levels. If the spindles feel excessively hot, it is advisable to inspect and address the cause promptly.

- 5. Leaking or Contaminated Grease: Grease leakage or contamination around the spindle area can indicate a problem with the bearings or the spindle seal. Inspect the spindles for any signs of grease leaks or contamination. Excessive grease buildup or the presence of water or debris in the grease may indicate a need for spindle maintenance or bearing replacement.

- 6. Visual Inspection: Regular visual inspection of the spindles is crucial for identifying any visible signs of damage, corrosion, or wear. Look for cracks, fractures, or deformities in the spindle structure. Inspect the spindle surface for signs of rust or corrosion that can weaken the spindle’s integrity. Additionally, check for any loose or missing components, such as nuts or bolts, that secure the spindle to the trailer frame.

- 7. Professional Inspection: If you are uncertain about the condition of the trailer spindles or if you notice any of the aforementioned signs, it is advisable to seek a professional inspection. A qualified mechanic or trailer specialist can perform a thorough examination of the spindles, bearings, and associated components to accurately diagnose any issues and recommend appropriate maintenance or replacement.

Proactive monitoring, regular inspection, and prompt diagnosis of any signs indicating a need for trailer spindle replacement or maintenance are crucial for maintaining safe towing conditions. It is important to address spindle issues promptly to prevent further damage, ensure optimal performance, and minimize the risk of accidents or failures during towing.

How do trailer spindles impact the performance and safety of a towing system?

Trailer spindles play a crucial role in influencing the performance and safety of a towing system. Here’s a detailed explanation of how trailer spindles impact towing system performance and safety:

- Wheel Attachment and Stability:

Trailer spindles provide the attachment point for the trailer wheels. They secure the wheels to the trailer and ensure proper alignment and stability during towing. A well-designed and properly installed spindle contributes to the overall stability of the trailer, minimizing the risk of wheel detachment, wobbling, or excessive vibrations. This enhances the towing system’s performance and improves safety on the road.

- Load Distribution:

Trailer spindles play a crucial role in distributing the weight of the load across the trailer axle. As the load is transferred from the trailer frame to the wheels through the spindles, they help maintain proper load distribution. Balanced load distribution is vital for safe towing, as it minimizes the risk of overloading certain wheels or axles, which could lead to instability and compromised handling.

- Strength and Durability:

The strength and durability of trailer spindles directly impact the towing system’s performance and safety. Spindles should be designed and manufactured to withstand the weight and forces exerted on the trailer during towing. High-quality spindles made from robust materials, such as steel, provide the necessary strength and durability to handle the load and maintain stability. Weak or compromised spindles can lead to failures, resulting in accidents or damage to the trailer and other vehicles.

- Wheel Alignment and Tracking:

Proper wheel alignment and tracking are critical for the safe operation of a towing system. Trailer spindles play a role in maintaining the correct alignment of the wheels. Misaligned wheels can cause uneven tire wear, reduced fuel efficiency, and compromised stability during towing. Well-designed spindles ensure that the wheels are aligned correctly, promoting smooth and predictable towing performance.

- Smooth and Controlled Towing:

Trailer spindles contribute to achieving smooth and controlled towing experiences. They facilitate smooth wheel rotation, allowing the wheels to spin freely and reduce friction. Smooth rotation enhances the overall performance of the towing system, promoting better fuel efficiency, reduced wear on trailer components, and improved handling and control.

- Compatibility with Suspension System:

Trailer spindles need to work in conjunction with the trailer’s suspension system. The spindle design and specifications should be compatible with the suspension components, such as leaf springs or torsion axles. Proper compatibility ensures that the spindles can handle the movement and forces generated by the suspension system, maintaining stability and minimizing the impact of uneven or rough road surfaces.

- Compliance with Safety Standards:

Trailer spindles must meet safety standards and regulations to ensure the overall safety of the towing system. Compliance with these standards ensures that the spindles are designed, manufactured, and installed to provide the necessary strength, stability, and reliability for safe towing operations.

In summary, trailer spindles have a significant impact on the performance and safety of a towing system. They contribute to wheel attachment and stability, facilitate load distribution, provide strength and durability, influence wheel alignment and tracking, enable smooth and controlled towing, ensure compatibility with the suspension system, and comply with safety standards. Choosing high-quality spindles and ensuring proper installation and maintenance are essential for a safe and reliable towing experience.

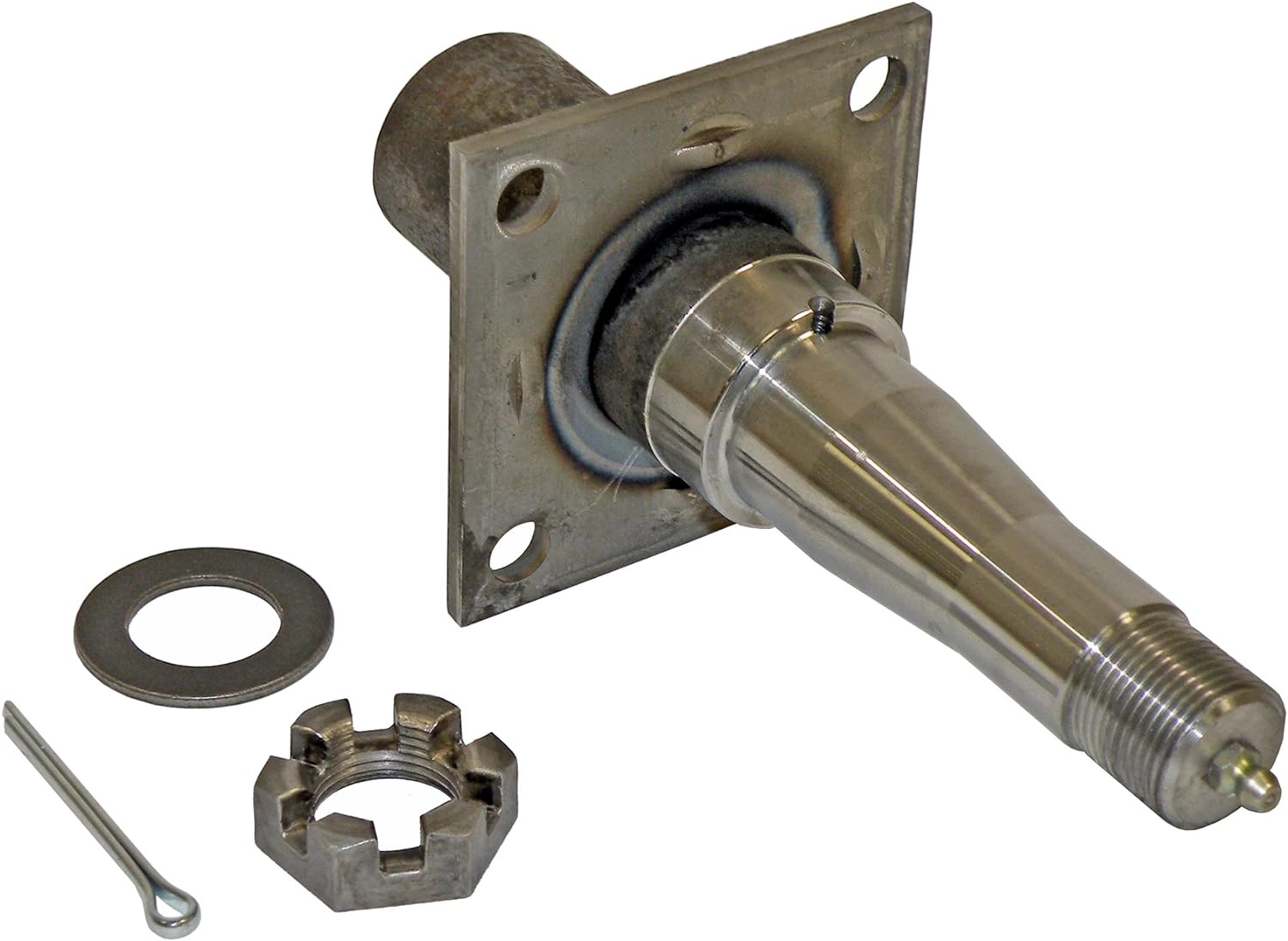

What is a trailer spindle, and what role does it play in a trailer’s construction?

A trailer spindle is a crucial component in the construction of a trailer. It serves a vital role in supporting and facilitating the movement of the trailer’s wheels. Here’s a detailed explanation of what a trailer spindle is and its significance in a trailer’s construction:

A trailer spindle is a shaft-like component that connects the trailer axle to the wheel hub. It is typically made of high-strength steel and is responsible for supporting the weight of the trailer and facilitating the rotation of the wheels. The spindle is mounted within the wheel hub assembly and allows the wheel to rotate smoothly and securely.

The trailer spindle performs several important functions:

- Wheel Attachment: The spindle provides a secure attachment point for the trailer wheels. It is designed to fit into the wheel hub assembly and is often tapered to ensure a tight and reliable connection. The wheel is typically mounted on the spindle using lug nuts or bolts, which secure it in place.

- Load Bearing: The trailer spindle bears the weight of the trailer and its cargo. It transfers the load from the trailer’s frame and axle to the wheels, distributing the weight evenly across the axle. The spindle must be strong enough to withstand the weight and forces exerted on the wheels during trailer operation.

- Wheel Rotation: The spindle allows the trailer wheels to rotate freely. As the trailer moves, the spindle transfers the rotational force from the axle to the wheel hub, enabling the wheels to spin. This rotation is essential for the trailer’s mobility and maneuverability.

- Lubrication and Heat Dissipation: Some trailer spindles incorporate grease or oil seals and fittings to allow for lubrication. Proper lubrication reduces friction and wear between the spindle and the wheel hub, enhancing the overall performance and lifespan of the trailer’s wheels. Additionally, the spindle’s design facilitates heat dissipation, helping to prevent excessive heat buildup that can lead to component failure.

In summary, a trailer spindle is a vital component in a trailer’s construction. It serves as the connection between the axle and the wheel hub, providing a secure attachment point for the wheels and supporting the weight of the trailer. The spindle enables the wheels to rotate freely, facilitating the trailer’s mobility. It may also incorporate features for lubrication and heat dissipation to ensure proper functioning and longevity of the trailer’s wheels. Overall, the trailer spindle plays a critical role in maintaining the stability, safety, and performance of the trailer during operation.

editor by CX 2024-04-10