Product Description

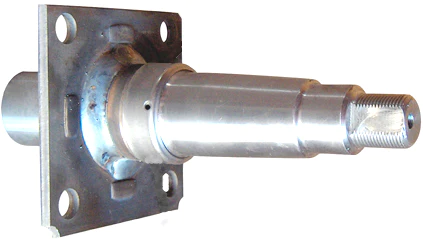

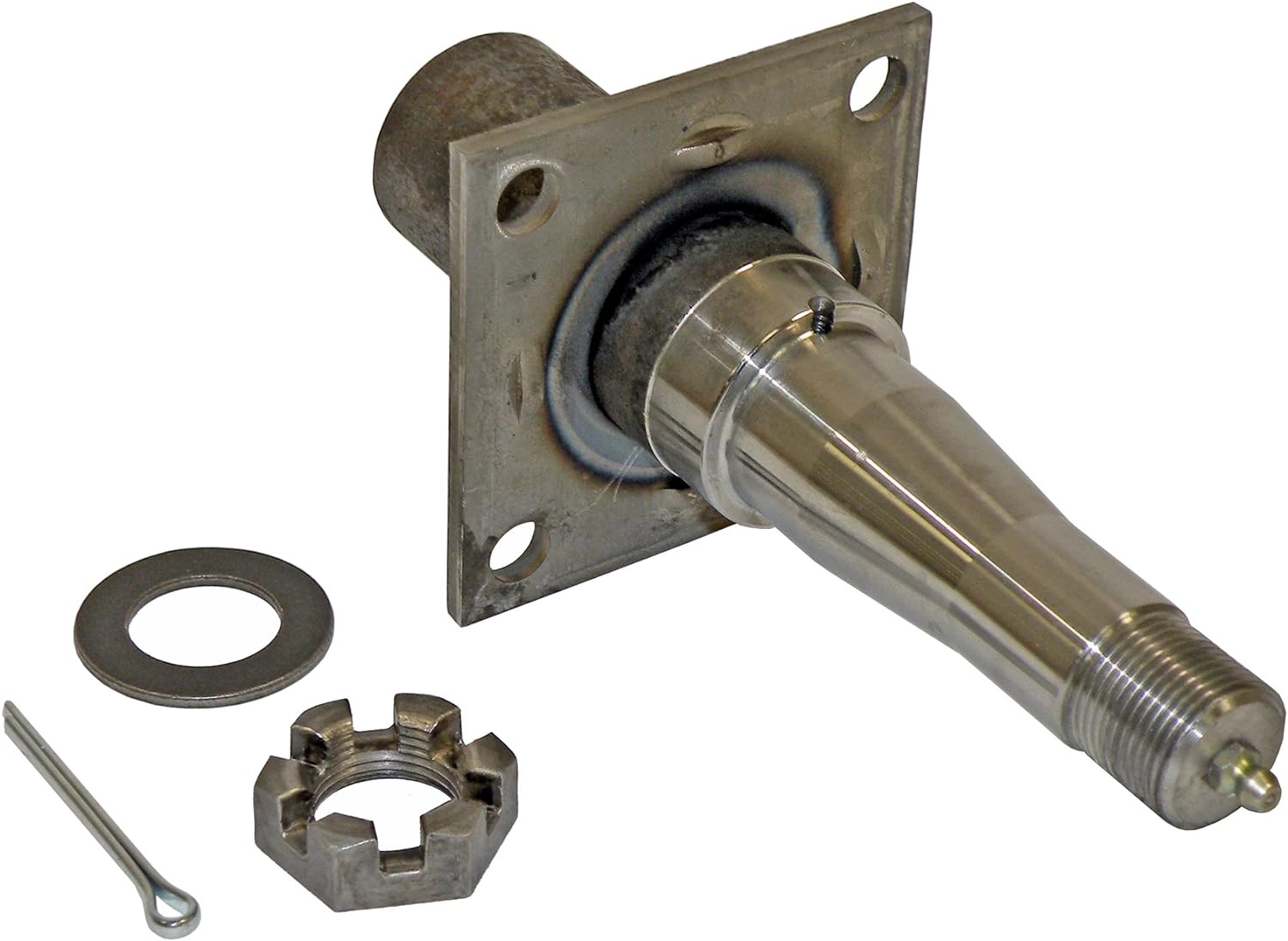

Customer designed High quality agricultural boat trailer parts accessories axle spindle

More qty,more discount

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon |

|---|---|

| Certification: | None |

| Car Make: | None |

| Position: | Rear |

| OEM: | No |

| Type: | Suspension Spring |

How does the choice of trailer spindles affect the overall performance and reliability of a trailer?

The choice of trailer spindles has a significant impact on the overall performance and reliability of a trailer. Here’s a detailed explanation:

- 1. Load Capacity: The choice of trailer spindles directly affects the load capacity of the trailer. Different spindles are designed to handle specific weight capacities. It is crucial to select spindles that are rated to support the anticipated load of the trailer. Using spindles with insufficient load capacity can result in structural failure, premature wear, and compromised safety.

- 2. Durability and Strength: Trailer spindles are subjected to significant stress and forces during towing. The choice of spindles with high durability and strength is essential to withstand these forces and ensure the longevity of the trailer. Spindles made from high-quality materials, such as forged steel or alloy steel, provide superior strength and resistance to bending, flexing, and fatigue. Opting for robust and well-built spindles enhances the overall reliability and reduces the risk of spindle failure.

- 3. Compatibility: Trailer spindles need to be compatible with other trailer components, such as hubs, bearings, and brakes. Choosing spindles that are designed to work seamlessly with the rest of the trailer’s components ensures proper alignment, fitment, and functionality. Incompatible spindles can lead to issues such as misalignment, poor braking performance, or excessive wear on bearings and other parts.

- 4. Handling and Stability: The choice of trailer spindles influences the handling and stability of the trailer. Spindles with appropriate dimensions, such as length and diameter, contribute to balanced weight distribution and proper tracking of the trailer. Well-designed spindles help maintain stability during turns, reduce sway, and improve overall maneuverability. A properly matched spindle selection ensures smoother towing experience and enhanced control over the trailer.

- 5. Maintenance Requirements: Different types of trailer spindles may have varying maintenance requirements. Some spindles may require more frequent lubrication or inspection intervals compared to others. Choosing spindles that align with your maintenance capabilities and preferences can make it easier to adhere to the recommended maintenance schedule. Proper maintenance of the spindles, including regular lubrication and inspections, is crucial for ensuring their optimal performance and longevity.

- 6. Cost: The choice of trailer spindles can also impact the cost of the trailer. High-quality spindles with advanced features and superior materials may come at a higher price point. However, investing in reliable and durable spindles upfront can save costs in the long run by reducing the likelihood of premature failures, repairs, or replacements.

Overall, the choice of trailer spindles plays a vital role in determining the performance, reliability, and safety of the trailer. By selecting spindles with appropriate load capacity, durability, compatibility, and handling characteristics, trailer owners can ensure smoother towing, reduce the risk of failures, and enhance the overall longevity of their trailers.

How does the choice of materials impact the durability and reliability of trailer spindles?

The choice of materials for trailer spindles has a significant impact on their durability and reliability. Here’s a detailed explanation:

The materials used in the construction of trailer spindles play a crucial role in determining their strength, corrosion resistance, and overall performance. Different materials offer varying levels of durability and reliability in different operating conditions and environments.

- Steel:

Steel is a commonly used material for trailer spindles due to its excellent strength and durability. Steel spindles are known for their ability to withstand heavy loads and provide reliable performance. They are often preferred for applications that require high load capacities, such as commercial trailers or trailers used in demanding industries. Steel spindles can handle rough terrains, frequent use, and challenging towing conditions.

- Aluminum:

Aluminum spindles offer several advantages, including lightweight construction and corrosion resistance. They are commonly used in applications where weight reduction is important, such as recreational trailers or trailers that require improved fuel efficiency. Aluminum spindles provide good durability and reliability while reducing the overall weight of the trailer, which can result in improved towing performance.

- Ductile Iron:

Ductile iron spindles offer a combination of strength, durability, and cost-effectiveness. They are known for their ability to withstand heavy loads and provide reliable performance in various towing applications. Ductile iron spindles are often chosen for their high strength-to-weight ratio and resistance to wear and deformation.

- Composite Materials:

Composite materials, such as fiberglass-reinforced polymers, are gaining popularity in the manufacturing of trailer spindles. These materials offer advantages such as high strength-to-weight ratio, corrosion resistance, and reduced maintenance requirements. Composite spindles can provide excellent durability and reliability while being lighter in weight compared to traditional materials like steel or iron.

When selecting the material for trailer spindles, it’s important to consider the specific requirements of the towing application. Factors such as load capacity, operating conditions, and environmental factors should be taken into account. Additionally, it’s crucial to follow the manufacturer’s recommendations regarding material selection to ensure compatibility with other trailer components and adherence to safety standards.

In summary, the choice of materials significantly impacts the durability and reliability of trailer spindles. Steel spindles offer excellent strength and durability, while aluminum spindles provide lightweight construction and corrosion resistance. Ductile iron spindles offer a combination of strength and cost-effectiveness. Composite materials offer a lightweight alternative with high strength-to-weight ratios. By selecting the appropriate material based on the specific towing requirements, trailer owners can ensure the longevity, performance, and reliability of their trailer spindles.

Can you describe the factors to consider when selecting trailer spindles for specific applications?

When selecting trailer spindles for specific applications, several factors should be taken into consideration. Here’s a detailed explanation of the factors to consider:

- Trailer Type and Purpose:

The type of trailer and its intended purpose play a significant role in determining the appropriate spindles. Different trailers, such as utility trailers, boat trailers, RV trailers, or horse trailers, have varying weight capacities, load requirements, and operating conditions. Understanding the specific trailer type and purpose helps in selecting spindles that can handle the expected loads and provide optimal stability.

- Load Capacity:

The load capacity of the trailer is a crucial consideration when selecting spindles. It is important to determine the maximum weight the trailer will carry, including the weight of the cargo or equipment. Spindles must be chosen to accommodate the expected load capacity to ensure safe and reliable operation.

- Wheel Size and Configuration:

The size and configuration of the trailer wheels are important factors in spindle selection. The spindle should be compatible with the wheel hub assembly and match the wheel bolt pattern. Additionally, the spindle may need to accommodate specific wheel sizes or tire configurations, especially in trailers where different wheel sizes are used.

- Environmental Factors:

The operating environment of the trailer should be considered when selecting spindles. For trailers exposed to corrosive environments, such as boat trailers used in saltwater, spindles with corrosion-resistant coatings or materials should be chosen to ensure durability and longevity.

- Compatibility with Axle and Suspension:

The spindle should be compatible with the trailer’s axle and suspension system. Consideration should be given to the type of axle (leaf spring, torsion, etc.) and the suspension configuration to ensure proper fit and functionality. The spindle should work in conjunction with the axle and suspension system to provide optimal stability and performance.

- Manufacturer Recommendations:

It is important to consult the trailer manufacturer’s recommendations or specifications when selecting spindles. The manufacturer’s guidelines provide valuable information about the appropriate spindle type, size, and other factors specific to the trailer model. Following the manufacturer’s recommendations helps ensure compatibility and adherence to safety standards.

- Regulatory Requirements:

Depending on the region and specific trailer application, there may be regulatory requirements or standards that dictate the selection of spindles. It is essential to be aware of and comply with these regulations to ensure legal operation and safety compliance.

- Expert Advice:

When in doubt or faced with unique trailer requirements, seeking expert advice from trailer manufacturers, suppliers, or industry professionals is recommended. They can provide valuable insights and recommendations based on their expertise and experience.

In summary, when selecting trailer spindles for specific applications, it is important to consider factors such as the trailer type and purpose, load capacity, wheel size and configuration, environmental factors, compatibility with axle and suspension, manufacturer recommendations, regulatory requirements, and seek expert advice when needed. Taking these factors into account ensures the appropriate selection of spindles that can handle the load, provide stability, and meet the specific requirements of the trailer and its intended use.

editor by CX 2023-12-25