Product Description

Product Description

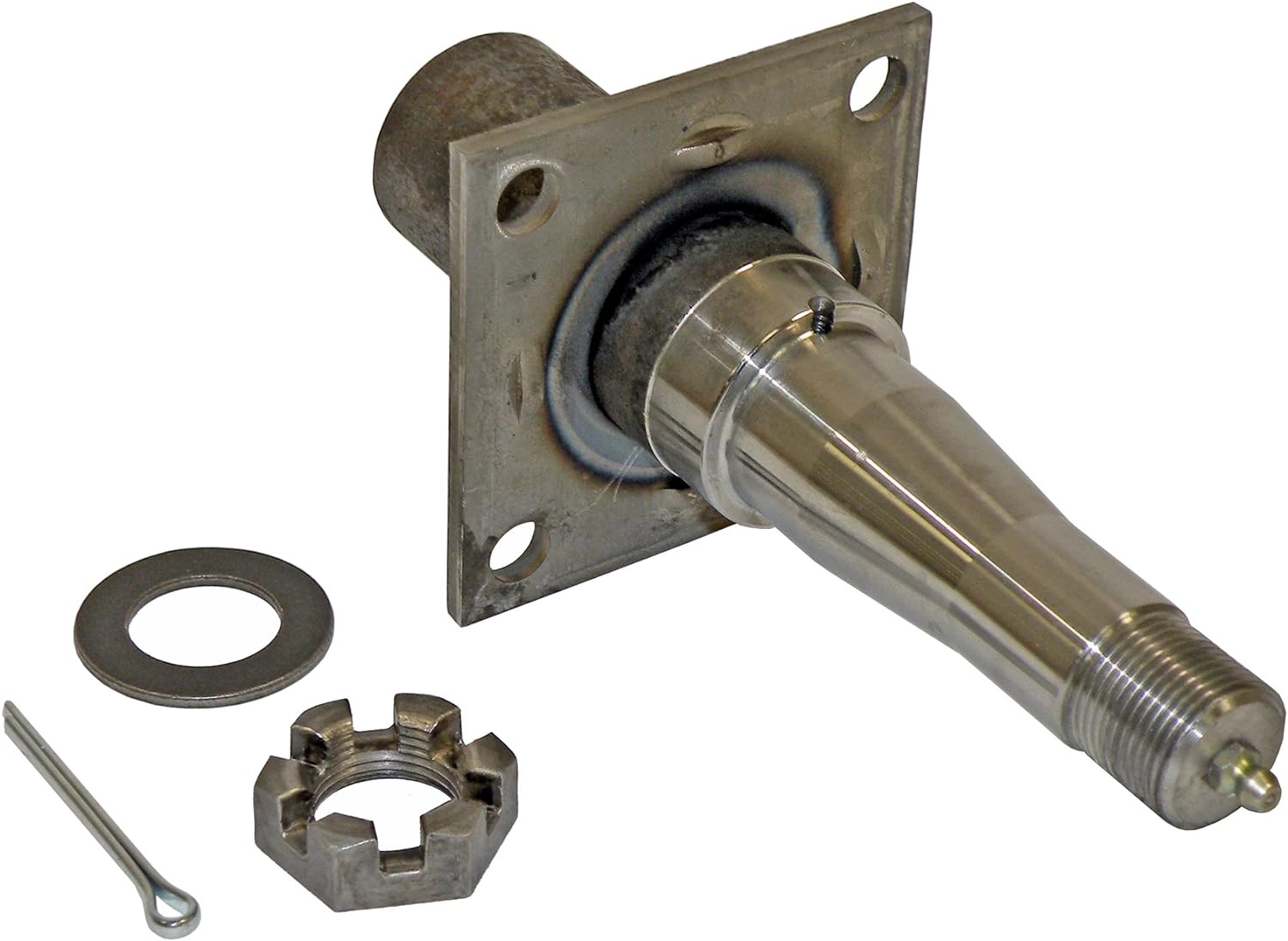

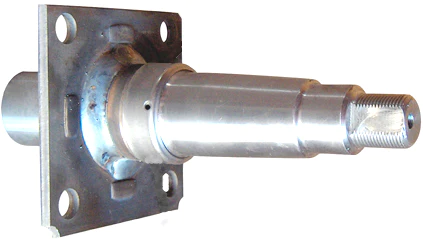

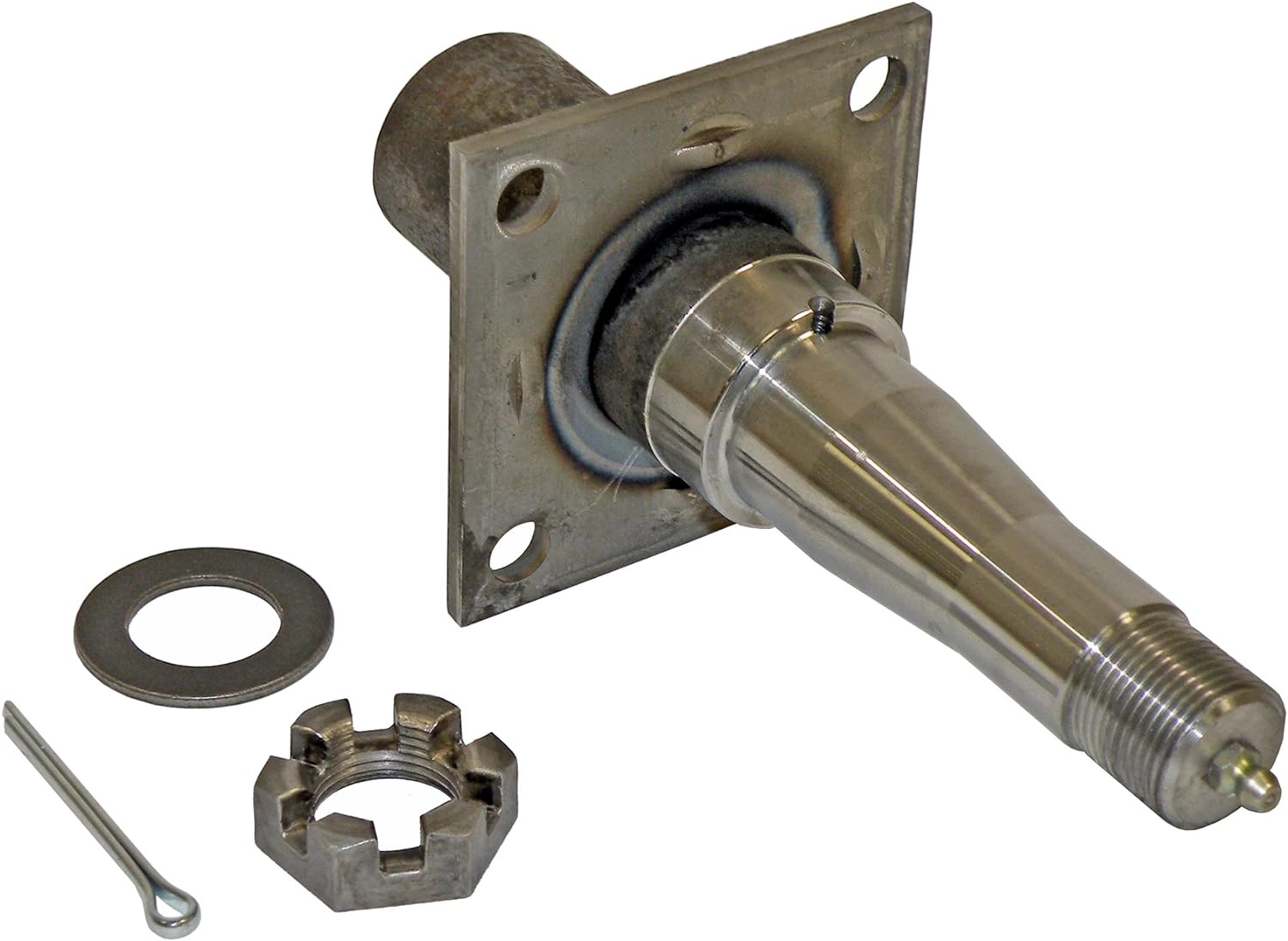

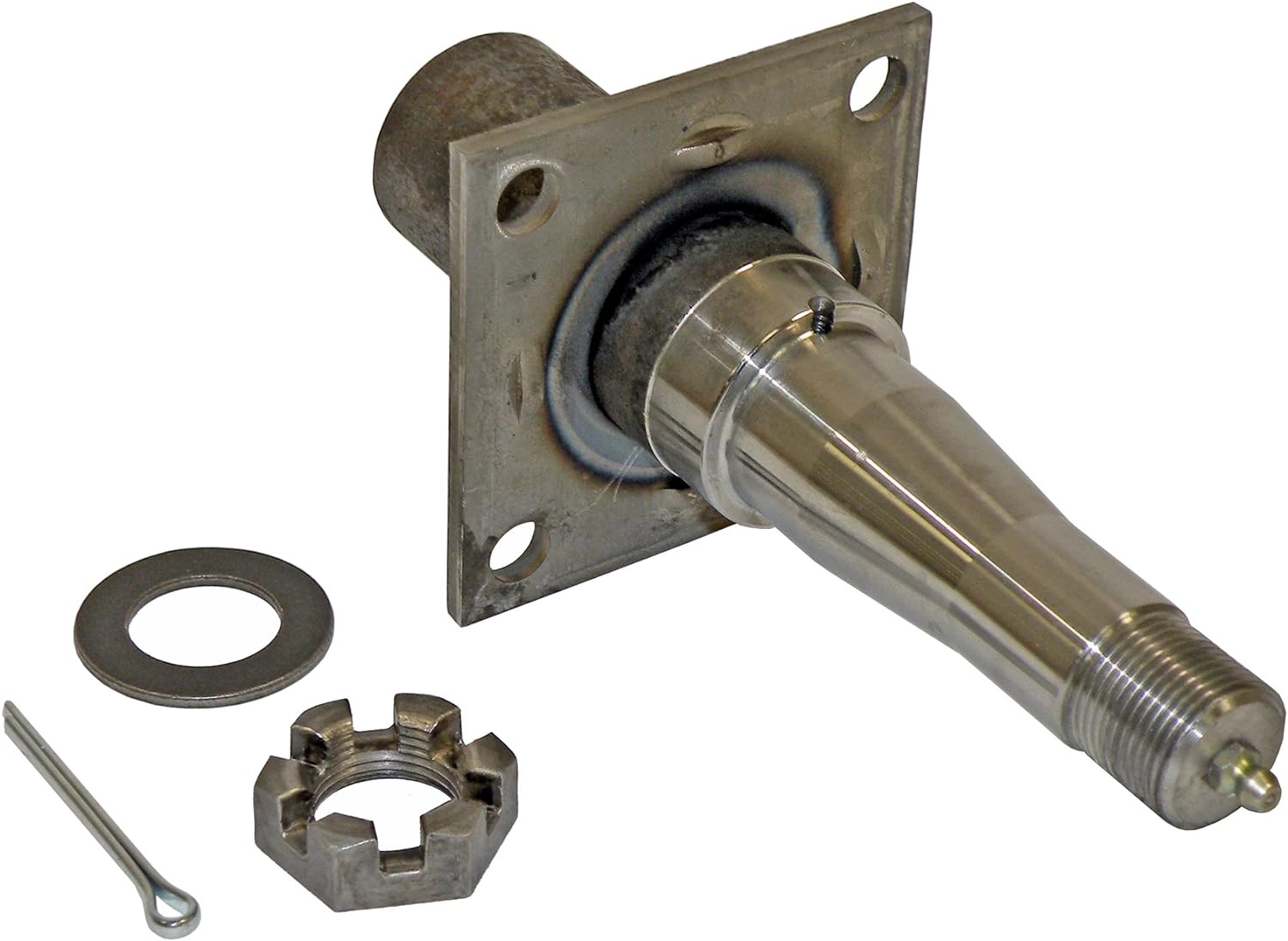

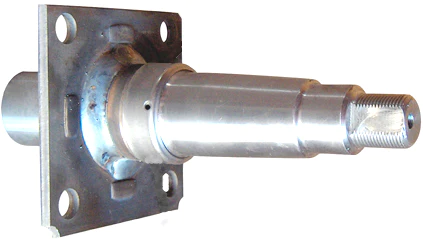

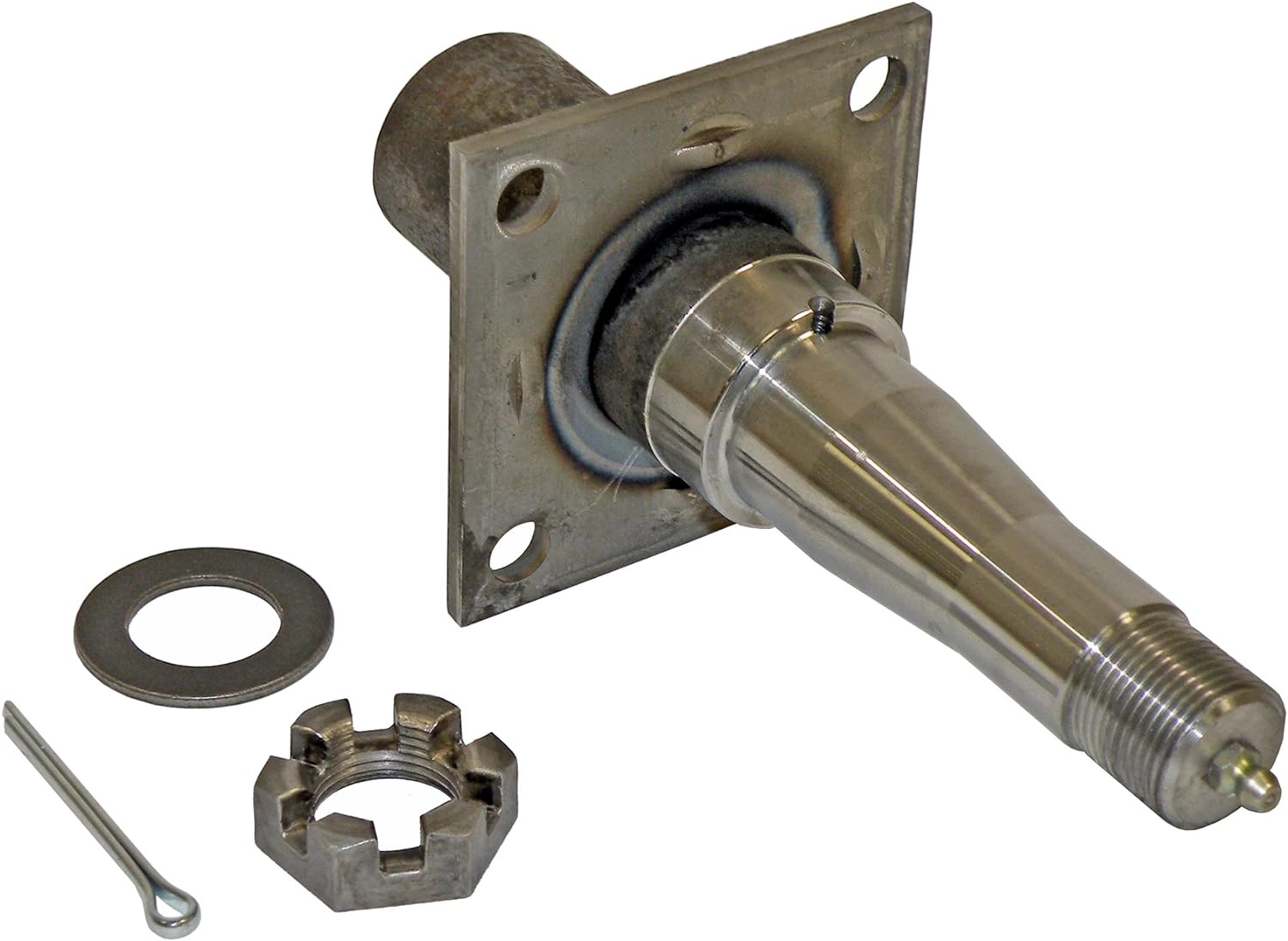

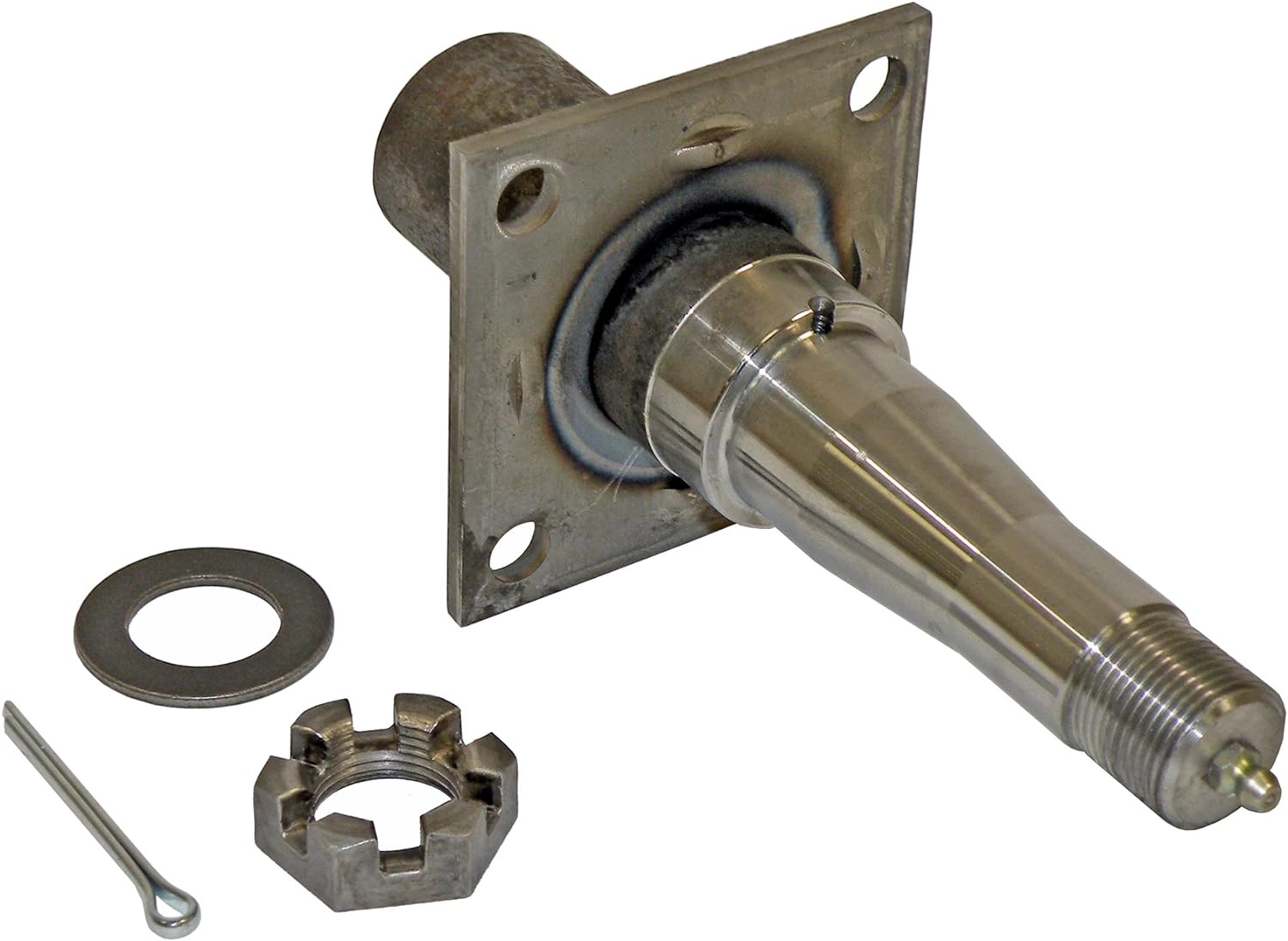

| 42# 35# Steel Spindle 7, 000 Lbs Trailer Axle Spindle for RV Trailer |

Introducing the 42# 35# Steel Spindle 7,000 Lbs Trailer Axle Spindle for RV Trailer, a high-quality and reliable component designed to enhance the performance and durability of your trailer. Crafted with precision and expertise, this steel spindle is the perfect choice for those seeking a dependable solution for their RV trailer.

Constructed from top-grade steel, this spindle boasts exceptional strength and resilience, ensuring it can withstand heavy loads and challenging terrains. With a weight capacity of 7,000 lbs, it is engineered to handle the demands of even the most demanding towing applications. Whether you’re hauling equipment, furniture, or recreational vehicles, this spindle will provide the stability and support you need.

The 42# 35# Steel Spindle is meticulously designed to meet the highest industry standards, guaranteeing a seamless fit and optimal performance. Its precise dimensions and flawless craftsmanship ensure a secure and stable connection between the axle and the trailer, minimizing the risk of accidents or damage during transportation.

This spindle is specifically tailored for RV trailers, making it an ideal choice for RV enthusiasts and professionals alike. Its compatibility with RV trailers ensures a hassle-free installation process, saving you time and effort. Additionally, its robust construction ensures longevity, reducing the need for frequent replacements and repairs.

When it comes to safety and reliability, this steel spindle excels. Its sturdy design and exceptional load-bearing capacity provide peace of mind, allowing you to tow your trailer with confidence. Whether you’re embarking on a cross-country adventure or simply transporting goods, this spindle will deliver the performance and durability you require.

Invest in the 42# 35# Steel Spindle 7,000 Lbs Trailer Axle Spindle for RV Trailer and experience the difference it can make in your towing experience. With its superior strength, precise fit, and unrivaled durability, this spindle is the ultimate choice for those seeking a top-tier solution for their RV trailer. Upgrade your towing capabilities today and enjoy a smoother, safer, and more efficient journey.

42# Steel Spindle for 5,200 lbs to 7,000 lbs Trailer Axle

| Specs | Application: 5,200-lb – 7,000-lb trailer axles Spindle capacity: 3,500 lbs Stub diameter: 2-1/4″ x 6″ long Overall spindle length: 11″ |

| Bearings | Inner bearing: 25580 (1.75″ inner diameter) |

| Outer bearing: 1.25″ inner diameter | |

| Races | Inner race: 25520 |

| Outer race: depends on outer bearing | |

| Grease seal | Inner diameter: 2.25″ |

| Outer diameter: 3.376″ |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Year |

|---|---|

| Warranty: | One Year |

| Type: | Brake System |

| Samples: |

US$ 25/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the role of bearings in conjunction with trailer spindles in towing systems?

Trailer bearings play a critical role in conjunction with trailer spindles in towing systems. Here’s an explanation of their role:

Trailer bearings are components that facilitate the smooth rotation of the trailer wheels around the spindles. They are located within the hub assembly and provide a low-friction interface between the stationary spindle and the rotating wheel. The bearings allow the trailer wheels to rotate freely while supporting the weight of the trailer and its cargo.

The primary functions of bearings in conjunction with trailer spindles are:

- Load Support: Bearings bear the weight of the trailer and its cargo, transferring the load from the axle to the wheels. They distribute the load evenly across the spindle, preventing excessive stress on any specific area and ensuring optimal load capacity.

- Reducing Friction: Bearings minimize friction between the stationary spindle and the rotating wheel hub. By providing a smooth, low-friction interface, they allow the wheels to rotate freely with minimal resistance. This reduces energy consumption and promotes efficient towing.

- Alignment and Stability: Bearings help maintain proper alignment and stability of the trailer wheels. They ensure that the wheels rotate in a straight line and prevent wobbling or uneven tire wear. This is crucial for safe and controlled towing, as improper wheel alignment can lead to handling issues and compromised stability.

- Shock Absorption: Bearings also play a role in absorbing shocks and vibrations encountered during towing. They provide a cushioning effect, reducing the impact of bumps and irregularities on the trailer wheels. This helps improve overall ride comfort and protects the trailer and its contents from excessive jolts or vibrations.

- Lubrication: Properly lubricated bearings reduce friction and heat generation. They also help prevent premature wear and damage to the bearing surfaces. Lubrication ensures smooth operation and extends the lifespan of the bearings and the overall functionality of the towing system.

It’s important to note that trailer bearings require regular maintenance, including inspection, cleaning, and lubrication, to ensure their optimal performance and longevity. Neglecting bearing maintenance can lead to overheating, premature wear, and ultimately, bearing failure, which can result in costly repairs and unsafe towing conditions.

When selecting bearings for trailer spindles, it’s crucial to choose high-quality bearings that are appropriate for the load capacity and towing conditions. It’s recommended to follow the manufacturer’s guidelines regarding bearing specifications, lubrication intervals, and maintenance procedures to ensure proper functioning of the bearings in conjunction with the trailer spindles.

In summary, trailer bearings are essential components in towing systems that work in conjunction with trailer spindles. They support the load, reduce friction, maintain alignment and stability, absorb shocks, and require regular maintenance to ensure optimal functionality and safe towing operations.

How does the choice of materials impact the durability and reliability of trailer spindles?

The choice of materials for trailer spindles has a significant impact on their durability and reliability. Here’s a detailed explanation:

The materials used in the construction of trailer spindles play a crucial role in determining their strength, corrosion resistance, and overall performance. Different materials offer varying levels of durability and reliability in different operating conditions and environments.

- Steel:

Steel is a commonly used material for trailer spindles due to its excellent strength and durability. Steel spindles are known for their ability to withstand heavy loads and provide reliable performance. They are often preferred for applications that require high load capacities, such as commercial trailers or trailers used in demanding industries. Steel spindles can handle rough terrains, frequent use, and challenging towing conditions.

- Aluminum:

Aluminum spindles offer several advantages, including lightweight construction and corrosion resistance. They are commonly used in applications where weight reduction is important, such as recreational trailers or trailers that require improved fuel efficiency. Aluminum spindles provide good durability and reliability while reducing the overall weight of the trailer, which can result in improved towing performance.

- Ductile Iron:

Ductile iron spindles offer a combination of strength, durability, and cost-effectiveness. They are known for their ability to withstand heavy loads and provide reliable performance in various towing applications. Ductile iron spindles are often chosen for their high strength-to-weight ratio and resistance to wear and deformation.

- Composite Materials:

Composite materials, such as fiberglass-reinforced polymers, are gaining popularity in the manufacturing of trailer spindles. These materials offer advantages such as high strength-to-weight ratio, corrosion resistance, and reduced maintenance requirements. Composite spindles can provide excellent durability and reliability while being lighter in weight compared to traditional materials like steel or iron.

When selecting the material for trailer spindles, it’s important to consider the specific requirements of the towing application. Factors such as load capacity, operating conditions, and environmental factors should be taken into account. Additionally, it’s crucial to follow the manufacturer’s recommendations regarding material selection to ensure compatibility with other trailer components and adherence to safety standards.

In summary, the choice of materials significantly impacts the durability and reliability of trailer spindles. Steel spindles offer excellent strength and durability, while aluminum spindles provide lightweight construction and corrosion resistance. Ductile iron spindles offer a combination of strength and cost-effectiveness. Composite materials offer a lightweight alternative with high strength-to-weight ratios. By selecting the appropriate material based on the specific towing requirements, trailer owners can ensure the longevity, performance, and reliability of their trailer spindles.

What are the different types and sizes of trailer spindles available in the market?

Trailer spindles come in various types and sizes to accommodate different trailer configurations and towing requirements. Here’s a detailed explanation of the different types and sizes of trailer spindles available in the market:

- Straight Spindle:

The straight spindle is the most common type of trailer spindle. It features a straight design without any taper. These spindles are typically used in trailers that require a simple and straightforward wheel attachment.

- Tapered Spindle:

Tapered spindles have a tapered shape, with the diameter gradually decreasing from the base towards the end. The taper allows for a secure and tight fit when the spindle is inserted into the wheel hub assembly. Tapered spindles are widely used in trailers and provide enhanced stability by minimizing the potential for wheel detachment.

- Parallel Spindle:

Parallel spindles have a consistent diameter throughout their length and do not feature a taper. These spindles offer simplicity and ease of installation, making them suitable for certain trailer applications where a tapered design is not required.

- Stepped Spindle:

Stepped spindles have a stepped or multi-diameter design. They feature different diameter sections along their length, allowing for compatibility with wheels of varying sizes. Stepped spindles are often used in trailers that need to accommodate different wheel sizes or in situations where wheel upgrades are common.

- Standard Sizes:

Trailer spindles are available in standardized sizes to ensure compatibility with various trailer components. The most common spindle sizes include 1-inch, 1-1/16-inch, 1-3/8-inch, and 1-3/4-inch diameters. These sizes are commonly used in light to medium-duty trailers.

- Heavy-Duty Sizes:

For heavy-duty trailers, larger spindle sizes are available to accommodate higher load capacities. These sizes can range from 2 inches to 3-1/2 inches in diameter, depending on the specific requirements of the trailer.

- Custom Sizes:

In addition to the standard sizes, custom spindle sizes can be manufactured to meet specific trailer specifications or unique applications. These custom spindles are designed and produced based on the specific requirements provided by the trailer manufacturer or the customer.

It’s worth noting that the availability of different types and sizes of trailer spindles may vary depending on the region and specific manufacturers. It is essential to consult with trailer manufacturers, suppliers, or industry professionals to determine the appropriate spindle type and size for a particular trailer application.

In summary, the market offers various types and sizes of trailer spindles, including straight, tapered, parallel, and stepped spindles. Standard sizes range from 1 inch to 1-3/4 inches, while heavy-duty sizes can be larger, from 2 inches to 3-1/2 inches in diameter. Custom spindle sizes are also available to meet specific trailer requirements. Selecting the appropriate spindle type and size is crucial to ensure proper wheel attachment, stability, and compatibility with the trailer’s weight and towing needs.

editor by CX 2024-03-14

China Standard 1.25 Inch Diameter Trailer Spindle for 2500 Lbs Trailer Axle

Product Description

Product Description

1.25 Inch Diameter Trailer Spindle for 2500 Lbs Trailer Axle

Specs:

| Specs | Application: 2,500-lb trailer axles |

| Stub diameter: 1-5/16″ | |

| Spindle capacity: 1,250 lbs | |

| Overall spindle length: 6-11/16″ | |

| Brake flange configuration: 4 bolt | |

| Bearings | Inner bearing: L44649 (1.063″ inner diameter) |

| Outer bearing: L44649 (1.063″ inner diameter) | |

| Races | Inner race: L44610 |

| Outer race: L44610 | |

| Grease seal | Inner diameter: 1.50″ |

| Outer diameter: 1.987″ |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Year |

|---|---|

| Warranty: | One Year |

| Type: | Brake System |

| Material: | Steel |

| Position: | Rear |

| Certification: | IATF-16949, ISO9001, DOT |

| Samples: |

US$ 25/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do trailer spindles contribute to the adaptability and versatility of trailers in various settings?

Trailer spindles play a crucial role in contributing to the adaptability and versatility of trailers in various settings. Here’s a detailed explanation:

Trailer spindles are the components that connect the wheels to the trailer frame and axle. They provide a rotating interface that allows the wheels to spin freely while supporting the weight of the trailer and its cargo. The design and features of trailer spindles enable them to enhance the adaptability and versatility of trailers in the following ways:

- Compatibility with Different Axles: Trailer spindles are designed to be compatible with various types of axles, including straight axles, torsion axles, and independent suspension systems. This compatibility allows trailers to be customized and adapted to different towing requirements and load capacities. Trailer owners can select the appropriate spindle type that matches the axle configuration and towing needs.

- Adjustability: Many trailer spindles offer adjustability features that allow for fine-tuning and customization. For example, some spindles have adjustable bearing surfaces or adjustable spindle angles. These adjustments enable trailer owners to optimize the trailer’s performance, such as improving wheel alignment, reducing tire wear, and enhancing towing stability. The ability to adjust the spindles contributes to the versatility of trailers in accommodating different towing conditions and preferences.

- Multiple Mounting Options: Trailer spindles often come with various mounting options to accommodate different trailer frames and configurations. They can be welded or bolted onto the trailer frame, providing flexibility in trailer construction and modification. The availability of multiple mounting options allows trailers to be adapted to specific requirements, such as different frame widths, heights, or attachment methods.

- Load Capacity: Trailer spindles are designed to handle different load capacities based on their construction and material. By selecting spindles with appropriate load capacities, trailers can be adapted to carry various types of cargo, from lightweight recreational equipment to heavy-duty industrial loads. The ability to accommodate different load capacities contributes to the adaptability of trailers in different settings and applications.

- Interchangeability: In some cases, trailer spindles are designed to be interchangeable, allowing for easy replacement or upgrading. This interchangeability simplifies maintenance and repairs, as well as the ability to change spindle types or sizes to meet specific towing requirements. Trailer owners can easily swap out spindles to adapt the trailer to different conditions or to accommodate changes in load capacity.

Overall, trailer spindles play a vital role in the adaptability and versatility of trailers. Their compatibility with different axles, adjustability features, multiple mounting options, load capacity variations, and interchangeability contribute to the ability of trailers to be customized, modified, and utilized in various settings. Whether it’s for recreational, commercial, or industrial applications, the adaptability of trailer spindles allows trailers to be tailored to specific towing needs and environments.

Can trailer spindles be customized for specific trailer types or load capacities?

Yes, trailer spindles can be customized to meet the specific requirements of different trailer types or load capacities. Here’s a detailed explanation:

Trailer spindles are available in various sizes, configurations, and materials to accommodate different trailer types and load capacities. Manufacturers offer a range of spindle options designed to meet specific application needs.

- Trailer Types:

Trailer spindles can be customized to suit different trailer types such as utility trailers, boat trailers, RV trailers, horse trailers, and more. Each trailer type may have unique requirements in terms of load capacity, axle configuration, wheel size, and operating conditions. Customized spindles are designed to fit the specific dimensions and specifications of the trailer type.

- Load Capacities:

Trailer spindles can be customized to handle varying load capacities. The load capacity of a trailer is determined by factors such as the trailer’s construction, axle rating, suspension system, and intended use. Customized spindles can be engineered to accommodate the specific load capacity requirements, ensuring that they are robust enough to handle the expected weight without compromising safety or performance.

- Materials and Construction:

Trailer spindles can be customized based on the materials used and their construction. Different materials, such as steel or aluminum, may be chosen depending on factors such as strength, weight, and corrosion resistance. Customized spindles can be manufactured using specific materials and construction techniques to meet the desired performance characteristics and environmental considerations.

- Braking Systems:

Customized trailer spindles can be designed to accommodate specific braking systems. Some trailers may require spindles with integrated brake provisions or compatibility with specific brake assemblies, such as hydraulic or electric brakes. Customization ensures that the spindles are properly configured to work in conjunction with the trailer’s braking system, enhancing safety and control during towing.

- Manufacturer Recommendations:

When customizing trailer spindles, it is important to consider the manufacturer’s recommendations or specifications. The trailer manufacturer can provide guidance on the suitable spindle options based on the trailer model, intended use, and performance requirements. Following the manufacturer’s recommendations ensures compatibility and adherence to warranty and safety standards.

It’s worth noting that while customization options are available, it is essential to work with reputable manufacturers or suppliers with expertise in trailer components. They can provide guidance, technical support, and ensure that the customized spindles meet the necessary quality and safety standards.

In summary, trailer spindles can be customized to match specific trailer types or load capacities. Customization allows for the selection of spindles that are tailored to the trailer’s requirements in terms of load capacity, materials, construction, and braking systems. By considering manufacturer recommendations and working with trusted suppliers, customized spindles can be obtained to ensure optimal performance, safety, and compatibility with the trailer.

What are the different types and sizes of trailer spindles available in the market?

Trailer spindles come in various types and sizes to accommodate different trailer configurations and towing requirements. Here’s a detailed explanation of the different types and sizes of trailer spindles available in the market:

- Straight Spindle:

The straight spindle is the most common type of trailer spindle. It features a straight design without any taper. These spindles are typically used in trailers that require a simple and straightforward wheel attachment.

- Tapered Spindle:

Tapered spindles have a tapered shape, with the diameter gradually decreasing from the base towards the end. The taper allows for a secure and tight fit when the spindle is inserted into the wheel hub assembly. Tapered spindles are widely used in trailers and provide enhanced stability by minimizing the potential for wheel detachment.

- Parallel Spindle:

Parallel spindles have a consistent diameter throughout their length and do not feature a taper. These spindles offer simplicity and ease of installation, making them suitable for certain trailer applications where a tapered design is not required.

- Stepped Spindle:

Stepped spindles have a stepped or multi-diameter design. They feature different diameter sections along their length, allowing for compatibility with wheels of varying sizes. Stepped spindles are often used in trailers that need to accommodate different wheel sizes or in situations where wheel upgrades are common.

- Standard Sizes:

Trailer spindles are available in standardized sizes to ensure compatibility with various trailer components. The most common spindle sizes include 1-inch, 1-1/16-inch, 1-3/8-inch, and 1-3/4-inch diameters. These sizes are commonly used in light to medium-duty trailers.

- Heavy-Duty Sizes:

For heavy-duty trailers, larger spindle sizes are available to accommodate higher load capacities. These sizes can range from 2 inches to 3-1/2 inches in diameter, depending on the specific requirements of the trailer.

- Custom Sizes:

In addition to the standard sizes, custom spindle sizes can be manufactured to meet specific trailer specifications or unique applications. These custom spindles are designed and produced based on the specific requirements provided by the trailer manufacturer or the customer.

It’s worth noting that the availability of different types and sizes of trailer spindles may vary depending on the region and specific manufacturers. It is essential to consult with trailer manufacturers, suppliers, or industry professionals to determine the appropriate spindle type and size for a particular trailer application.

In summary, the market offers various types and sizes of trailer spindles, including straight, tapered, parallel, and stepped spindles. Standard sizes range from 1 inch to 1-3/4 inches, while heavy-duty sizes can be larger, from 2 inches to 3-1/2 inches in diameter. Custom spindle sizes are also available to meet specific trailer requirements. Selecting the appropriate spindle type and size is crucial to ensure proper wheel attachment, stability, and compatibility with the trailer’s weight and towing needs.

editor by CX 2024-03-14

China factory TRAILER SPINDLE FOR 3,500 LB #84 AXLE WELD ON 1 7/16 INCH ROUND WITH BRAKE FLANGE

Product Description

Trailer Stub Axles

| PN. | Axle Size(P) | Capacity | Bearing | Length(L) |

| TA036 | 39mm Round | 375 kg | LM | custom-made |

| TA037 | 40mm Square | 500 kg | LM | custom-made |

| TA038 | 45mm Round | 500-800 kg | SL | custom-made |

| TA039 | 45mm Square | 500-800 kg | SL | custom-made |

| TA040 | 50mm Round | 750-1100 kg | SL | custom-made |

| TA041 | 63mm Square | 1250-1750 kg | Parallel | custom-made |

| TA042 | 65mm Round | 1250-1750 kg | Parallel | custom-made |

| TA043 | 75mm Round | 1750-2500 kg | 3Ton | custom-made |

| TA044 | 75mm Square | 1750-2500 kg | 3Ton | custom-made |

Trailer parts to suit a complete axle rebuild or partial replacement.

- Hub kits to fit on a new or existing trailer axle

- Hub and stub kits that also include a weld on stub axle

- Braked or non braked hubs, disc brakes or drum brakes to suit a range of applications

- Wireless trailer brake controller systems

- Non-braked hubs and braked hub options

- Comprehensive spare parts, such as brake pads, stub axles, seal kits etc

HangZhou CHINAMFG Machinery Co., Ltd is a professional manufacturer of trailer parts in HangZhou, ZHangZhoug Province, China since 2016.

We can produce many trailer parts & accessories as follows: Towbars, axles, brake drums, hubs, brake disc, bearings, springs and springs and suspension kits, couplings, mudguards, U-Bolts, Jockey Wheels, keel rollers and brackets, wobble roller, wheel spacer, equalizers and all accessories related to trailers.

If you can send me the drawings or specifications of the trailer parts, mechanical parts and wheels, we can give you our price.

Q1: Do you have factory?

A: Yes, we have our own factory, own engineers, we can meet custom’s unique requirement.

Q2: Can I have a sample order?

A: Yes, welcome sample order to test and check quality. Mixed samples are acceptable.

Q3: It’s OK to print my logo on your product?

A: Yes, we can according to your exact requirement.

Q4:How do you ship the goods and how long does it take arrive?

A: We usually shipped by DHL, UPS, FedEx, it usually takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5: What is your advantages?

A: We are professional supplier for more than 10 years, we always put the quality and price at the first place. At the same time, our products are exported to various countries, we have full experience to solve thorny problems.

If you want to know about our products and us, welcome to enquiry and email me.thanks

1-Welcome OEM

- You can use your own brands or ours, if you use our brand, our professional team will help you design the packing.

2-Our service

- You inquiry related to our products or prices will be replied in 24 hours.

- Well-trained and experienced staffs to answer all your enquirys in fluent English.

- Protection of your sales area, ideas of your design and all your private information.

- We have a QC team, every product will be checked by them before packed.

3-Welcome to visit

- When you come to our company visit us, we will arrange a car for picking up and help you book hotel. If you want to visit the local scenic spot, our colleague will accompany you.

4-Warranty

- Customer should be provide the video and the pictures for the problem products.

- Products returned within the warranty period must bear product number & date code.

5-After service

- In production and after delivery, we will track on time and tell you goods situation.

- When the goods arrived, if you find any design and quality questions, or difference from your samples, please feel free to contact us, we will find the question and solve it with you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Axle Number: | 2 |

| Application: | Trailer |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the role of bearings in conjunction with trailer spindles in towing systems?

Trailer bearings play a critical role in conjunction with trailer spindles in towing systems. Here’s an explanation of their role:

Trailer bearings are components that facilitate the smooth rotation of the trailer wheels around the spindles. They are located within the hub assembly and provide a low-friction interface between the stationary spindle and the rotating wheel. The bearings allow the trailer wheels to rotate freely while supporting the weight of the trailer and its cargo.

The primary functions of bearings in conjunction with trailer spindles are:

- Load Support: Bearings bear the weight of the trailer and its cargo, transferring the load from the axle to the wheels. They distribute the load evenly across the spindle, preventing excessive stress on any specific area and ensuring optimal load capacity.

- Reducing Friction: Bearings minimize friction between the stationary spindle and the rotating wheel hub. By providing a smooth, low-friction interface, they allow the wheels to rotate freely with minimal resistance. This reduces energy consumption and promotes efficient towing.

- Alignment and Stability: Bearings help maintain proper alignment and stability of the trailer wheels. They ensure that the wheels rotate in a straight line and prevent wobbling or uneven tire wear. This is crucial for safe and controlled towing, as improper wheel alignment can lead to handling issues and compromised stability.

- Shock Absorption: Bearings also play a role in absorbing shocks and vibrations encountered during towing. They provide a cushioning effect, reducing the impact of bumps and irregularities on the trailer wheels. This helps improve overall ride comfort and protects the trailer and its contents from excessive jolts or vibrations.

- Lubrication: Properly lubricated bearings reduce friction and heat generation. They also help prevent premature wear and damage to the bearing surfaces. Lubrication ensures smooth operation and extends the lifespan of the bearings and the overall functionality of the towing system.

It’s important to note that trailer bearings require regular maintenance, including inspection, cleaning, and lubrication, to ensure their optimal performance and longevity. Neglecting bearing maintenance can lead to overheating, premature wear, and ultimately, bearing failure, which can result in costly repairs and unsafe towing conditions.

When selecting bearings for trailer spindles, it’s crucial to choose high-quality bearings that are appropriate for the load capacity and towing conditions. It’s recommended to follow the manufacturer’s guidelines regarding bearing specifications, lubrication intervals, and maintenance procedures to ensure proper functioning of the bearings in conjunction with the trailer spindles.

In summary, trailer bearings are essential components in towing systems that work in conjunction with trailer spindles. They support the load, reduce friction, maintain alignment and stability, absorb shocks, and require regular maintenance to ensure optimal functionality and safe towing operations.

What advantages do certain types of trailer spindles offer compared to others?

Trailer spindles come in various types, and each type offers unique advantages compared to others. Here’s a detailed explanation:

- Straight Spindles:

Straight spindles are the most common type and offer several advantages:

- Cost-Effective: Straight spindles are relatively simple in design and construction, making them cost-effective compared to other types.

- Wide Availability: Straight spindles are widely available, making them easy to find and replace if needed.

- Easy Maintenance: Straight spindles are relatively easy to maintain and service, requiring fewer specialized tools or techniques.

- Tapered Spindles:

Tapered spindles provide their own set of advantages:

- Increased Load Capacity: Tapered spindles are designed to handle higher load capacities compared to straight spindles of similar size. The tapered shape enhances their strength and load-bearing capabilities.

- Better Alignment: Tapered spindles offer improved wheel alignment as they allow for precise fitment of the wheel hub assembly. This helps in maintaining proper tracking and reduces tire wear.

- Enhanced Stability: The taper design of these spindles contributes to enhanced stability during towing, reducing the risk of wheel wobbling or vibrations.

- Drop Spindles:

Drop spindles offer specific advantages for certain trailer applications:

- Lowered Trailer Height: Drop spindles are designed to lower the trailer’s ride height, allowing for easier loading and unloading of cargo or equipment.

- Improved Ground Clearance: By lowering the trailer height, drop spindles can also improve ground clearance, reducing the risk of bottoming out on uneven terrain.

- Enhanced Aerodynamics: The lower trailer height achieved with drop spindles can improve aerodynamics, leading to potential fuel efficiency gains.

- Brake Spindles:

Brake spindles offer advantages when used with trailer braking systems:

- Integrated Braking: Brake spindles are designed to accommodate brake assemblies and provide a mounting point for the brake components, allowing for integrated braking systems.

- Improved Stopping Power: Brake spindles, when used with appropriate brake systems, enhance the trailer’s stopping power, improving overall safety during towing.

- Controlled Braking: Brake spindles provide better control and modulation of braking forces, allowing for smoother and more controlled stops.

It’s important to note that the advantages of certain types of trailer spindles may be more relevant to specific trailer applications or towing requirements. Consideration should also be given to factors such as load capacity, compatibility with other trailer components, and manufacturer recommendations when selecting the appropriate spindle type for a given application.

In summary, certain types of trailer spindles offer advantages over others. Straight spindles are cost-effective, widely available, and easy to maintain. Tapered spindles provide increased load capacity, better alignment, and enhanced stability. Drop spindles lower the trailer height, improve ground clearance, and enhance aerodynamics. Brake spindles offer integrated braking, improved stopping power, and controlled braking. Understanding the advantages of different spindle types helps in selecting the most suitable option based on specific trailer requirements and towing needs.

What are the different types and sizes of trailer spindles available in the market?

Trailer spindles come in various types and sizes to accommodate different trailer configurations and towing requirements. Here’s a detailed explanation of the different types and sizes of trailer spindles available in the market:

- Straight Spindle:

The straight spindle is the most common type of trailer spindle. It features a straight design without any taper. These spindles are typically used in trailers that require a simple and straightforward wheel attachment.

- Tapered Spindle:

Tapered spindles have a tapered shape, with the diameter gradually decreasing from the base towards the end. The taper allows for a secure and tight fit when the spindle is inserted into the wheel hub assembly. Tapered spindles are widely used in trailers and provide enhanced stability by minimizing the potential for wheel detachment.

- Parallel Spindle:

Parallel spindles have a consistent diameter throughout their length and do not feature a taper. These spindles offer simplicity and ease of installation, making them suitable for certain trailer applications where a tapered design is not required.

- Stepped Spindle:

Stepped spindles have a stepped or multi-diameter design. They feature different diameter sections along their length, allowing for compatibility with wheels of varying sizes. Stepped spindles are often used in trailers that need to accommodate different wheel sizes or in situations where wheel upgrades are common.

- Standard Sizes:

Trailer spindles are available in standardized sizes to ensure compatibility with various trailer components. The most common spindle sizes include 1-inch, 1-1/16-inch, 1-3/8-inch, and 1-3/4-inch diameters. These sizes are commonly used in light to medium-duty trailers.

- Heavy-Duty Sizes:

For heavy-duty trailers, larger spindle sizes are available to accommodate higher load capacities. These sizes can range from 2 inches to 3-1/2 inches in diameter, depending on the specific requirements of the trailer.

- Custom Sizes:

In addition to the standard sizes, custom spindle sizes can be manufactured to meet specific trailer specifications or unique applications. These custom spindles are designed and produced based on the specific requirements provided by the trailer manufacturer or the customer.

It’s worth noting that the availability of different types and sizes of trailer spindles may vary depending on the region and specific manufacturers. It is essential to consult with trailer manufacturers, suppliers, or industry professionals to determine the appropriate spindle type and size for a particular trailer application.

In summary, the market offers various types and sizes of trailer spindles, including straight, tapered, parallel, and stepped spindles. Standard sizes range from 1 inch to 1-3/4 inches, while heavy-duty sizes can be larger, from 2 inches to 3-1/2 inches in diameter. Custom spindle sizes are also available to meet specific trailer requirements. Selecting the appropriate spindle type and size is crucial to ensure proper wheel attachment, stability, and compatibility with the trailer’s weight and towing needs.

editor by CX 2024-03-13

China Custom 2-1/4″ Diameter 5200 Lb 7000 Lb Trailer Axle Spindle for Trailer Use

Product Description

Our factory

Loading

FAQ:

Q1: How do you guarantee quality?

A: We take quality inspect records from raw material to finished product.

The former department bear 100% responsibility for next process to guarantee quality.

Q2: Can you produce if we have samples only?

A: Our technical ability is strong enough to deal with different types of spring.

Sample drawing and customers’ interests will be protected well.

Q3: Is it possible to have sample for quality testing?

A: Same or similar sample are available for free.

Q4: What is your MOQ?

A: For common material size, MOQ requires 30~50 pcs;

For special material size, Moq requires 3 ton or more;

Q5: What about the package of the product?

A:The goods will be packed according to your requirements and in well protection before delivery.

Q6: What is your terms of payment?

A: T/T, L/C at sight , Western Union.

Q7: What’s the delivery time ?

A: Most of parts are available in storage. For container delivery, 1 container can finish loading in 10 days.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 6 Month |

|---|---|

| Warranty: | 6 Month |

| Type: | Suspension |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the signs that indicate a need for trailer spindle replacement or maintenance, and how can they be diagnosed?

Proper maintenance and timely replacement of trailer spindles are essential for safe towing. Here’s a detailed explanation of the signs that indicate a need for spindle replacement or maintenance and how they can be diagnosed:

- 1. Excessive Play or Movement: If you notice excessive play or movement in the trailer wheels when jacked up or during towing, it may indicate worn-out or damaged spindles. To diagnose this, you can grasp the tire at the top and bottom and try to wiggle it. Excessive movement or play indicates a potential issue with the spindles that requires inspection and possible replacement.

- 2. Abnormal Noises: Unusual noises, such as grinding, squeaking, or rumbling sounds, coming from the trailer wheels while in motion can be a sign of spindle problems. These noises may indicate worn-out bearings, insufficient lubrication, or misaligned spindles. To diagnose the issue, you can listen for any unusual noises while towing or rotating the trailer wheels by hand. If abnormal sounds are present, it is recommended to inspect the spindles and bearings for damage or wear.

- 3. Irregular Tire Wear: Pay attention to the tire wear patterns on the trailer. If you notice uneven or abnormal tire wear, such as cupping, feathering, or bald spots, it could be an indication of misaligned or damaged spindles. To diagnose this, visually inspect the tires for any signs of uneven wear and check for any underlying issues with the spindles or suspension system.

- 4. Excessive Heat: Overheating of the trailer spindles can be a sign of bearing or lubrication problems. If you feel excessive heat when touching the spindle after a tow, it may indicate inadequate lubrication, worn-out bearings, or other issues. To diagnose this, carefully touch the spindles after towing and check for any unusual heat levels. If the spindles feel excessively hot, it is advisable to inspect and address the cause promptly.

- 5. Leaking or Contaminated Grease: Grease leakage or contamination around the spindle area can indicate a problem with the bearings or the spindle seal. Inspect the spindles for any signs of grease leaks or contamination. Excessive grease buildup or the presence of water or debris in the grease may indicate a need for spindle maintenance or bearing replacement.

- 6. Visual Inspection: Regular visual inspection of the spindles is crucial for identifying any visible signs of damage, corrosion, or wear. Look for cracks, fractures, or deformities in the spindle structure. Inspect the spindle surface for signs of rust or corrosion that can weaken the spindle’s integrity. Additionally, check for any loose or missing components, such as nuts or bolts, that secure the spindle to the trailer frame.

- 7. Professional Inspection: If you are uncertain about the condition of the trailer spindles or if you notice any of the aforementioned signs, it is advisable to seek a professional inspection. A qualified mechanic or trailer specialist can perform a thorough examination of the spindles, bearings, and associated components to accurately diagnose any issues and recommend appropriate maintenance or replacement.

Proactive monitoring, regular inspection, and prompt diagnosis of any signs indicating a need for trailer spindle replacement or maintenance are crucial for maintaining safe towing conditions. It is important to address spindle issues promptly to prevent further damage, ensure optimal performance, and minimize the risk of accidents or failures during towing.

Can you provide examples of trailers or towing applications that commonly use spindles?

Trailer spindles are widely used in various types of trailers and towing applications. Here are some examples:

- Utility Trailers: Utility trailers, which are used for transporting a wide range of goods and equipment, commonly utilize spindles. These trailers can be found in industries such as construction, landscaping, and agriculture.

- Boat Trailers: Spindles are commonly used in boat trailers to secure the wheels and ensure proper alignment and stability during the transportation of boats to and from the water.

- RV Trailers: Recreational vehicles (RVs) often rely on spindles to support the weight of the trailer and provide a connection point for the wheels. Spindles play a crucial role in maintaining stability and ensuring a smooth towing experience for RV owners.

- Horse Trailers: Horse trailers utilize spindles to secure the wheels and provide stability during transportation. The safety and comfort of the horses being transported are dependent on the proper functioning of the spindles.

- Cargo Trailers: Cargo trailers, commonly used for commercial purposes or moving household goods, rely on spindles to support the weight of the trailer and provide a connection point for the wheels.

- Car Trailers: Trailers designed for transporting cars, such as car carriers or car haulers, utilize spindles to secure the wheels and ensure proper alignment during transportation.

- Travel Trailers: Travel trailers, which are towed behind vehicles for recreational purposes, commonly use spindles to support the weight of the trailer and provide stability during travel.

- Flatbed Trailers: Flatbed trailers, used for transporting large or irregularly shaped cargo, often rely on spindles to secure the wheels and ensure stability and load distribution.

- Enclosed Trailers: Enclosed trailers, commonly used for transporting goods or equipment that require protection from the elements, utilize spindles to support the wheels and ensure proper alignment.

These are just a few examples of trailers and towing applications that commonly use spindles. Spindles are a critical component in various types of trailers, ensuring the stability, load distribution, and safety of the towing system.

When selecting spindles for a specific trailer or towing application, it is important to consider factors such as load capacity, compatibility with other trailer components, and manufacturer recommendations to ensure optimal performance and safety.

What is a trailer spindle, and what role does it play in a trailer’s construction?

A trailer spindle is a crucial component in the construction of a trailer. It serves a vital role in supporting and facilitating the movement of the trailer’s wheels. Here’s a detailed explanation of what a trailer spindle is and its significance in a trailer’s construction:

A trailer spindle is a shaft-like component that connects the trailer axle to the wheel hub. It is typically made of high-strength steel and is responsible for supporting the weight of the trailer and facilitating the rotation of the wheels. The spindle is mounted within the wheel hub assembly and allows the wheel to rotate smoothly and securely.

The trailer spindle performs several important functions:

- Wheel Attachment: The spindle provides a secure attachment point for the trailer wheels. It is designed to fit into the wheel hub assembly and is often tapered to ensure a tight and reliable connection. The wheel is typically mounted on the spindle using lug nuts or bolts, which secure it in place.

- Load Bearing: The trailer spindle bears the weight of the trailer and its cargo. It transfers the load from the trailer’s frame and axle to the wheels, distributing the weight evenly across the axle. The spindle must be strong enough to withstand the weight and forces exerted on the wheels during trailer operation.

- Wheel Rotation: The spindle allows the trailer wheels to rotate freely. As the trailer moves, the spindle transfers the rotational force from the axle to the wheel hub, enabling the wheels to spin. This rotation is essential for the trailer’s mobility and maneuverability.

- Lubrication and Heat Dissipation: Some trailer spindles incorporate grease or oil seals and fittings to allow for lubrication. Proper lubrication reduces friction and wear between the spindle and the wheel hub, enhancing the overall performance and lifespan of the trailer’s wheels. Additionally, the spindle’s design facilitates heat dissipation, helping to prevent excessive heat buildup that can lead to component failure.

In summary, a trailer spindle is a vital component in a trailer’s construction. It serves as the connection between the axle and the wheel hub, providing a secure attachment point for the wheels and supporting the weight of the trailer. The spindle enables the wheels to rotate freely, facilitating the trailer’s mobility. It may also incorporate features for lubrication and heat dissipation to ensure proper functioning and longevity of the trailer’s wheels. Overall, the trailer spindle plays a critical role in maintaining the stability, safety, and performance of the trailer during operation.

editor by CX 2024-03-13

China Custom High Quality Trailer Axle Spindle with 6 Stubs Idler Hub Assembly Camper Trailer Use

Product Description

PRODUCT CHARACTERISTICS of Heavy Duty Low Price 13tons Truck Semi Trailer Axle Type

1. One-piece high quality special heat tube, low alloy steel shaft bearing capacity is strong, light weight, long life and other characteristics;

2. Product configuration wear sensor alarm device;

3. The wheel hub system maintenance simple, wearing parts in any place can buy;

4. The caliper, brake disc, gas chamber adopts domestic CHINAMFG brand, has many characteristics, such as crack resistance, long service life

5. Special heat treatment, low alloy steel axle beam, good comprehensive performance, strong bearing capacity, low dead weight;

6. High quality alloy CHINAMFG spindle provides superior fatigue resistance through integral heat treatment;

7. Camshaft adopts special sealing processing to ensure that grease will not enter the brake drum, which is more safe;

Specification of Heavy Duty Low Price 13tons Truck Semi Trailer Axle Type

. New tight fit wheel hubcap, O-ring seal, good sealing performance;

F: Shaft Tube Construction Code:

F-150 Integral Square axis

H-150Square axis for welding

K-127 Integral Square axis

W-120Integral Square axis

Y-127 integral round shaft

R-146 integral round shaft

N-152 integral round shaft

D-89 welding round shaft

S-120Square axis for welding

. Extend the free maintenance time

|

item |

value |

|

Use |

Trailer Parts |

|

Parts |

Trailer Axles |

|

Max Payload |

13ton |

|

Size |

1840mm |

|

Place of CHINAMFG |

China |

|

Brand Name |

CHINAMFG |

|

Product Name |

Trailer Axle |

|

Material |

Steel |

|

Color |

Customer Demands |

|

MOQ |

1 pc |

|

Package |

Standard Package |

Suspension For Trailer: wooden tray or others ways according to your requirements.

CHINAMFG Export all kinds of trailers, trailer parts and Man-hand Welding Machinery, Automatic Welding machinery, Trailer Production Line,trailer Axle, brake assemblies , backing plates,brake drums and hubs Etc. We can supply the right product in shortest ways and cheapest value.

Competitive steady-going quality, competitive prices and better services, our products are well exported to North America, Europe and Oceania. Strong technical force, sophisticated manufacturing equipment, professional production team, for product innovation, research and development, quality assurance provides a CHINAMFG backing.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free After Service |

|---|---|

| Warranty: | Free After Service |

| Type: | Axle |

| Certification: | ISO/TS16949, CCC, ISO |

| Loading Weight: | 25T |

| ABS: | Without ABS |

| Samples: |

US$ 1200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What safety considerations should be taken into account when using trailer spindles in towing?

When using trailer spindles in towing, several safety considerations should be taken into account. Here’s a detailed explanation:

- Proper Installation: Ensure that the trailer spindles are installed correctly according to the manufacturer’s guidelines. This includes securely attaching the spindles to the trailer frame and using appropriate hardware and torque specifications. Improper installation can compromise the structural integrity of the trailer and lead to handling issues or failure during towing.

- Regular Inspection and Maintenance: Regularly inspect the trailer spindles for signs of wear, damage, or misalignment. Check for any cracks, corrosion, or loose components. Additionally, inspect the bearings, seals, and lubrication system to ensure they are in good condition. Perform routine maintenance tasks such as greasing the bearings and replacing worn-out parts as recommended by the manufacturer.

- Proper Weight Distribution: Ensure that the trailer’s load is properly distributed to avoid overloading the spindles or placing excessive stress on specific components. Follow the manufacturer’s guidelines for the trailer’s maximum load capacity and distribute the weight evenly across the axles. Improper weight distribution can lead to instability, reduced braking performance, and increased risk of accidents.

- Appropriate Speed and Driving Behavior: Adhere to safe driving practices when towing a trailer. Maintain a safe and appropriate speed, considering the load, road conditions, and legal limits. Avoid sudden maneuvers, excessive braking, and rapid acceleration, as they can exert additional stress on the spindles and other towing components.

- Tire Maintenance: Properly maintained tires are essential for safe towing. Ensure that the trailer tires are properly inflated, have adequate tread depth, and are in good overall condition. Uneven tire wear or worn-out tires can affect the stability and handling of the trailer, potentially leading to accidents or tire blowouts.

- Proper Hitching and Coupling: Ensure that the trailer is properly hitched and coupled to the towing vehicle. Use a hitch that matches the trailer’s weight capacity, and ensure that the coupling mechanism is engaged securely. Improper hitching or coupling can result in trailer detachment, loss of control, or accidents.

- Trailer Braking System: If the trailer is equipped with brakes, ensure that the braking system is properly maintained and functioning correctly. Regularly inspect and test the brakes to ensure they provide adequate stopping power and are synchronized with the towing vehicle’s braking system.

- Safe Loading and Securing of Cargo: Properly load and secure the cargo in the trailer to prevent shifting, imbalance, or load loss during towing. Use appropriate tie-downs, straps, or cargo nets to secure the load and ensure it does not exceed the trailer’s weight capacity.

- Weather and Road Conditions: Consider the impact of weather and road conditions on towing safety. Adjust driving behavior and speed accordingly, especially in adverse weather conditions such as rain, snow, or strong winds. Be cautious on uneven or slippery road surfaces to maintain control and stability.

- Emergency Preparedness: Equip the towing vehicle and trailer with essential safety equipment, including a spare tire, jack, lug wrench, reflective triangles, and a fire extinguisher. Familiarize yourself with emergency procedures and know how to handle potential towing-related emergencies.

Following these safety considerations when using trailer spindles in towing can help ensure a safe and secure towing experience. It is essential to prioritize regular maintenance, adhere to recommended guidelines, and exercise caution while operating a trailer to prevent accidents, minimize risks, and protect both yourself and other road users.

How does the choice of materials impact the durability and reliability of trailer spindles?

The choice of materials for trailer spindles has a significant impact on their durability and reliability. Here’s a detailed explanation:

The materials used in the construction of trailer spindles play a crucial role in determining their strength, corrosion resistance, and overall performance. Different materials offer varying levels of durability and reliability in different operating conditions and environments.

- Steel:

Steel is a commonly used material for trailer spindles due to its excellent strength and durability. Steel spindles are known for their ability to withstand heavy loads and provide reliable performance. They are often preferred for applications that require high load capacities, such as commercial trailers or trailers used in demanding industries. Steel spindles can handle rough terrains, frequent use, and challenging towing conditions.

- Aluminum:

Aluminum spindles offer several advantages, including lightweight construction and corrosion resistance. They are commonly used in applications where weight reduction is important, such as recreational trailers or trailers that require improved fuel efficiency. Aluminum spindles provide good durability and reliability while reducing the overall weight of the trailer, which can result in improved towing performance.

- Ductile Iron:

Ductile iron spindles offer a combination of strength, durability, and cost-effectiveness. They are known for their ability to withstand heavy loads and provide reliable performance in various towing applications. Ductile iron spindles are often chosen for their high strength-to-weight ratio and resistance to wear and deformation.

- Composite Materials:

Composite materials, such as fiberglass-reinforced polymers, are gaining popularity in the manufacturing of trailer spindles. These materials offer advantages such as high strength-to-weight ratio, corrosion resistance, and reduced maintenance requirements. Composite spindles can provide excellent durability and reliability while being lighter in weight compared to traditional materials like steel or iron.

When selecting the material for trailer spindles, it’s important to consider the specific requirements of the towing application. Factors such as load capacity, operating conditions, and environmental factors should be taken into account. Additionally, it’s crucial to follow the manufacturer’s recommendations regarding material selection to ensure compatibility with other trailer components and adherence to safety standards.

In summary, the choice of materials significantly impacts the durability and reliability of trailer spindles. Steel spindles offer excellent strength and durability, while aluminum spindles provide lightweight construction and corrosion resistance. Ductile iron spindles offer a combination of strength and cost-effectiveness. Composite materials offer a lightweight alternative with high strength-to-weight ratios. By selecting the appropriate material based on the specific towing requirements, trailer owners can ensure the longevity, performance, and reliability of their trailer spindles.

In what types of trailers are spindles commonly used, and how do they vary?

Trailer spindles are commonly used in various types of trailers, and their design can vary depending on the specific trailer application. Here’s a detailed explanation of the types of trailers where spindles are commonly used and how they can vary:

- Utility Trailers:

Utility trailers, including flatbed trailers, equipment trailers, and landscape trailers, often utilize spindles. These trailers are commonly used for transporting a wide range of goods and equipment. The spindles used in utility trailers can vary in size, load-bearing capacity, and configuration to accommodate different trailer sizes and weight requirements.

- Boat Trailers:

Boat trailers are designed to transport boats of various sizes and types. Spindles used in boat trailers are typically designed to withstand corrosive environments due to exposure to water and may incorporate special coatings or materials to enhance durability. They can also have unique features such as bearing buddies or seals to provide additional protection against water intrusion and lubrication.

- RV and Camper Trailers:

Recreational vehicles (RVs) and camper trailers often employ spindles to support the wheels and axles. These spindles are designed to handle the weight of the living quarters and amenities found in these trailers. They may have specific load-bearing capacities and configurations to meet the requirements of different RV and camper trailer sizes and designs.

- Horse Trailers:

Horse trailers are used for transporting horses and typically feature spindles to support the wheels. These spindles are designed to withstand the additional dynamic loads and stresses associated with transporting live animals. They may have features such as grease fittings or sealed bearings for ease of maintenance and durability.

- Cargo Trailers:

Cargo trailers are used for transporting goods and merchandise. They often incorporate spindles to support the wheels and accommodate the weight of the cargo. The design of spindles used in cargo trailers can vary depending on the trailer’s size, load capacity, and intended use.

- Travel Trailers and Caravans:

Travel trailers and caravans are towable living quarters designed for recreational travel. They utilize spindles to support the wheels and axles. The spindles used in travel trailers and caravans can vary depending on the trailer’s size, weight, and specific features. They may incorporate features for ease of maintenance and durability, such as grease fittings or sealed bearings.

In summary, spindles are commonly used in a wide range of trailers, including utility trailers, boat trailers, RV and camper trailers, horse trailers, cargo trailers, and travel trailers. The design of spindles can vary based on the specific trailer application, including size, weight capacity, load-bearing requirements, and environmental considerations. These variations ensure that the spindles are well-suited to the demands of different trailer types and provide reliable support for the wheels and axles during towing.

editor by CX 2024-03-12

China Good quality Trailer Axle Drop Spindle, Tapered for 1 3/8″ x 1 1/16″ bearings, 2900-3750lb Axles #34398

Product Description

Manufacturer’s Part Number: SP-HF-IF-84L

Spindle Size: #84

Axle Size: 3,500

For Axle Tube Size: 2-3/8″ Round

Spindle Weight Rating: 1,750 lbs

Grease Type: Easy lube with grease zerk

Flange Size: 4 bolt 10″ Brakes

| Part Name | Material | Process | Spindle Weight Rating | Application |

| Easy Lube Spindle | C45 | Hot forged | 3,500 lbs | used for the 10″ or 12″ electric or hydraulic drum brake assemblies |

Trailer parts to suit a complete axle rebuild or partial replacement.

- Hub kits to fit on a new or existing trailer axle

- Hub and stub kits that also include a weld on stub axle

- Braked or non braked hubs, disc brakes or drum brakes to suit a range of applications

- Wireless trailer brake controller systems

- Non-braked hubs and braked hub options

- Comprehensive spare parts, such as brake pads, stub axles, seal kits etc

HangZhou CHINAMFG Machinery Co., Ltd is a professional manufacturer of trailer parts in HangZhou, ZHangZhoug Province, China since 2016.

We can produce many trailer parts & accessories as follows: Towbars, axles, brake drums, hubs, brake disc, bearings, springs and springs and suspension kits, couplings, mudguards, U-Bolts, Jockey Wheels, keel rollers and brackets, wobble roller, wheel spacer, equalizers and all accessories related to trailers.

If you can send me the drawings or specifications of the trailer parts, mechanical parts and wheels, we can give you our price.

Q1: Do you have factory?

A: Yes, we have our own factory, own engineers, we can meet custom’s unique requirement.

Q2: Can I have a sample order?

A: Yes, welcome sample order to test and check quality. Mixed samples are acceptable.

Q3: It’s OK to print my logo on your product?

A: Yes, we can according to your exact requirement.

Q4:How do you ship the goods and how long does it take arrive?

A: We usually shipped by DHL, UPS, FedEx, it usually takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5: What is your advantages?

A: We are professional supplier for more than 10 years, we always put the quality and price at the first place. At the same time, our products are exported to various countries, we have full experience to solve thorny problems.

If you want to know about our products and us, welcome to enquiry and email me.thanks

1-Welcome OEM

- You can use your own brands or ours, if you use our brand, our professional team will help you design the packing.

2-Our service

- You inquiry related to our products or prices will be replied in 24 hours.

- Well-trained and experienced staffs to answer all your enquirys in fluent English.

- Protection of your sales area, ideas of your design and all your private information.

- We have a QC team, every product will be checked by them before packed.

3-Welcome to visit

- When you come to our company visit us, we will arrange a car for picking up and help you book hotel. If you want to visit the local scenic spot, our colleague will accompany you.

4-Warranty

- Customer should be provide the video and the pictures for the problem products.

- Products returned within the warranty period must bear product number & date code.

5-After service

- In production and after delivery, we will track on time and tell you goods situation.

- When the goods arrived, if you find any design and quality questions, or difference from your samples, please feel free to contact us, we will find the question and solve it with you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Axle Number: | 2 |

| Application: | Trailer |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the signs that indicate a need for trailer spindle replacement or maintenance, and how can they be diagnosed?

Proper maintenance and timely replacement of trailer spindles are essential for safe towing. Here’s a detailed explanation of the signs that indicate a need for spindle replacement or maintenance and how they can be diagnosed:

- 1. Excessive Play or Movement: If you notice excessive play or movement in the trailer wheels when jacked up or during towing, it may indicate worn-out or damaged spindles. To diagnose this, you can grasp the tire at the top and bottom and try to wiggle it. Excessive movement or play indicates a potential issue with the spindles that requires inspection and possible replacement.

- 2. Abnormal Noises: Unusual noises, such as grinding, squeaking, or rumbling sounds, coming from the trailer wheels while in motion can be a sign of spindle problems. These noises may indicate worn-out bearings, insufficient lubrication, or misaligned spindles. To diagnose the issue, you can listen for any unusual noises while towing or rotating the trailer wheels by hand. If abnormal sounds are present, it is recommended to inspect the spindles and bearings for damage or wear.

- 3. Irregular Tire Wear: Pay attention to the tire wear patterns on the trailer. If you notice uneven or abnormal tire wear, such as cupping, feathering, or bald spots, it could be an indication of misaligned or damaged spindles. To diagnose this, visually inspect the tires for any signs of uneven wear and check for any underlying issues with the spindles or suspension system.

- 4. Excessive Heat: Overheating of the trailer spindles can be a sign of bearing or lubrication problems. If you feel excessive heat when touching the spindle after a tow, it may indicate inadequate lubrication, worn-out bearings, or other issues. To diagnose this, carefully touch the spindles after towing and check for any unusual heat levels. If the spindles feel excessively hot, it is advisable to inspect and address the cause promptly.

- 5. Leaking or Contaminated Grease: Grease leakage or contamination around the spindle area can indicate a problem with the bearings or the spindle seal. Inspect the spindles for any signs of grease leaks or contamination. Excessive grease buildup or the presence of water or debris in the grease may indicate a need for spindle maintenance or bearing replacement.

- 6. Visual Inspection: Regular visual inspection of the spindles is crucial for identifying any visible signs of damage, corrosion, or wear. Look for cracks, fractures, or deformities in the spindle structure. Inspect the spindle surface for signs of rust or corrosion that can weaken the spindle’s integrity. Additionally, check for any loose or missing components, such as nuts or bolts, that secure the spindle to the trailer frame.

- 7. Professional Inspection: If you are uncertain about the condition of the trailer spindles or if you notice any of the aforementioned signs, it is advisable to seek a professional inspection. A qualified mechanic or trailer specialist can perform a thorough examination of the spindles, bearings, and associated components to accurately diagnose any issues and recommend appropriate maintenance or replacement.

Proactive monitoring, regular inspection, and prompt diagnosis of any signs indicating a need for trailer spindle replacement or maintenance are crucial for maintaining safe towing conditions. It is important to address spindle issues promptly to prevent further damage, ensure optimal performance, and minimize the risk of accidents or failures during towing.

What advantages do certain types of trailer spindles offer compared to others?

Trailer spindles come in various types, and each type offers unique advantages compared to others. Here’s a detailed explanation:

- Straight Spindles:

Straight spindles are the most common type and offer several advantages:

- Cost-Effective: Straight spindles are relatively simple in design and construction, making them cost-effective compared to other types.

- Wide Availability: Straight spindles are widely available, making them easy to find and replace if needed.

- Easy Maintenance: Straight spindles are relatively easy to maintain and service, requiring fewer specialized tools or techniques.

- Tapered Spindles:

Tapered spindles provide their own set of advantages:

- Increased Load Capacity: Tapered spindles are designed to handle higher load capacities compared to straight spindles of similar size. The tapered shape enhances their strength and load-bearing capabilities.

- Better Alignment: Tapered spindles offer improved wheel alignment as they allow for precise fitment of the wheel hub assembly. This helps in maintaining proper tracking and reduces tire wear.

- Enhanced Stability: The taper design of these spindles contributes to enhanced stability during towing, reducing the risk of wheel wobbling or vibrations.

- Drop Spindles:

Drop spindles offer specific advantages for certain trailer applications:

- Lowered Trailer Height: Drop spindles are designed to lower the trailer’s ride height, allowing for easier loading and unloading of cargo or equipment.

- Improved Ground Clearance: By lowering the trailer height, drop spindles can also improve ground clearance, reducing the risk of bottoming out on uneven terrain.

- Enhanced Aerodynamics: The lower trailer height achieved with drop spindles can improve aerodynamics, leading to potential fuel efficiency gains.

- Brake Spindles:

Brake spindles offer advantages when used with trailer braking systems:

- Integrated Braking: Brake spindles are designed to accommodate brake assemblies and provide a mounting point for the brake components, allowing for integrated braking systems.

- Improved Stopping Power: Brake spindles, when used with appropriate brake systems, enhance the trailer’s stopping power, improving overall safety during towing.

- Controlled Braking: Brake spindles provide better control and modulation of braking forces, allowing for smoother and more controlled stops.

It’s important to note that the advantages of certain types of trailer spindles may be more relevant to specific trailer applications or towing requirements. Consideration should also be given to factors such as load capacity, compatibility with other trailer components, and manufacturer recommendations when selecting the appropriate spindle type for a given application.

In summary, certain types of trailer spindles offer advantages over others. Straight spindles are cost-effective, widely available, and easy to maintain. Tapered spindles provide increased load capacity, better alignment, and enhanced stability. Drop spindles lower the trailer height, improve ground clearance, and enhance aerodynamics. Brake spindles offer integrated braking, improved stopping power, and controlled braking. Understanding the advantages of different spindle types helps in selecting the most suitable option based on specific trailer requirements and towing needs.

Can you explain the primary functions and importance of trailer spindles in towing?

Trailer spindles play crucial functions and hold significant importance in towing operations. Here’s a detailed explanation of the primary functions and importance of trailer spindles in towing:

- Wheel Attachment:

The primary function of a trailer spindle in towing is to provide a secure attachment point for the trailer wheels. The spindle is designed to fit into the wheel hub assembly and allows for the installation of the wheels. It typically utilizes lug nuts or bolts to secure the wheel tightly to the spindle, ensuring that it remains in place during towing.

- Load Bearing:

Trailer spindles bear the weight of the trailer and its cargo. As the trailer moves, the weight is transferred from the trailer’s frame and axle to the wheels through the spindles. The spindles distribute the load evenly across the axle, ensuring that the weight is adequately supported. It is crucial for the spindles to be strong enough to handle the weight and forces exerted on the wheels during towing.

- Wheel Rotation:

Another essential function of trailer spindles is to facilitate the rotation of the wheels. As the towing vehicle moves forward, the spindles transfer the rotational force from the trailer axle to the wheel hubs, allowing the wheels to rotate freely. This rotation enables the trailer to move smoothly and maneuver effectively.

- Lubrication and Heat Dissipation:

Trailer spindles may incorporate features for lubrication and heat dissipation. Proper lubrication is essential to reduce friction and wear between the spindle and the wheel hub, ensuring smooth wheel rotation and minimizing the risk of damage. Some spindles include grease or oil seals and fittings that allow for regular lubrication. Additionally, the spindle’s design often includes mechanisms to dissipate heat generated during towing. Effective heat dissipation helps prevent excessive heat buildup, which can lead to component failure.

- Maintaining Stability and Control:

The proper functioning of trailer spindles is crucial for maintaining stability and control during towing. The secure attachment of the wheels to the spindles ensures that they remain in place, preventing wheel separation or instability. The even distribution of weight across the spindles promotes balanced towing, minimizing the risk of swaying or fishtailing. The smooth rotation of the wheels facilitated by the spindles enables precise maneuvering and control of the trailer.

- Overall Safety:

The importance of trailer spindles in towing cannot be overstated in terms of safety. Reliable and properly functioning spindles contribute to the overall safety of the towing operation. By securely attaching the wheels and maintaining stability, they help prevent accidents or incidents caused by wheel detachment, loss of control, or trailer instability. Proper lubrication and heat dissipation also minimize the risk of mechanical failures or damage that could compromise safety.